Low-shrinkage acrylic ester type vacuum impregnation agent for sealing reinforcement

A low-shrinkage acrylate and vacuum impregnation technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of labor, raw materials, energy waste, large contact area, corrosion, etc., and improve industrial production efficiency and volume Effect of low shrinkage and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

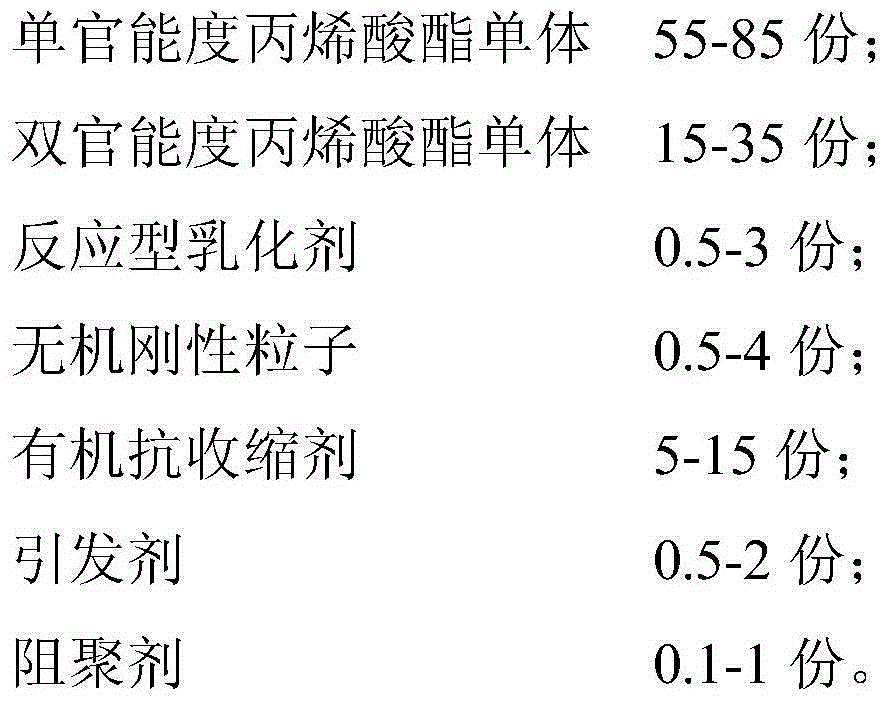

Method used

Image

Examples

Embodiment 1

[0019] Taking a representative acrylate impregnating agent formula as an example, its composition is 69 parts by weight of lauryl methacrylate, 16 parts of 1,6 hexanediol diacrylate, 8 parts of trimethylolpropane triacrylate Parts, modified alkylphenol polyoxyethylene ether 12 parts, dimethacrylate modified polyethylene glycol (400) 10 parts, silane coupling agent KH550 modified nano-silica 2 parts, azobisisobutyl 2 parts of nitrile, 0.04 part of hydroquinone. The specific steps are as follows:

[0020] (1) Add lauryl methacrylate, 1,6 hexanediol diacrylate, trimethylolpropane triacrylate, modified alkylphenol polyoxyethylene ether, modified nano-silica, modified polyethylene Diol, hydroquinone, stirring speed 300-600 rpm, stirring for 10-30 minutes;

[0021] (2) Add azobisisobutyronitrile, stir at a speed of 600-800 rpm, and stir for 20-40 minutes;

[0022] (3) Stand for 10-60 minutes.

[0023] The physical properties of the acrylate impregnating agent obtained by Example...

Embodiment 2

[0026] Taking a representative acrylate impregnating agent formula as an example, its composition is 66 parts by weight of isodecyl methacrylate, 9 parts of diethylene glycol dimethacrylate, trimethylolpropane three 7 parts of acrylate, 2 parts of fatty acid polyoxyethylene ester, 2 parts of silane coupling agent KH550 modified nano-silica, 7 parts of dimethacrylate modified polyethylene glycol (200), azobisisobutyronitrile 3.5 parts, 0.08 parts of 2,5-di-tert-butylhydroquinone. The specific steps are as follows:

[0027] (1) Add isodecyl methacrylate, ethylene glycol diacrylate, trimethylolpropane triacrylate, polyoxyethylene fatty acid ester, modified nano-silica, modified polyethylene glycol, 2,5-di-tert-butylhydroquinone, stirring speed 300-600 rpm, stirring for 10-30 minutes;

[0028] (2) Add azobisisobutyronitrile, stir at a speed of 600-800 rpm, and stir for 20-40 minutes;

[0029] (3) Stand for 10-60 minutes.

[0030] The physical properties of the acrylate impregn...

Embodiment 3

[0033] Taking a representative acrylate impregnating agent formula as an example, its composition is 64 parts by weight of stearyl methacrylate, 6 parts of triethylene glycol dimethacrylate, glycerol trimethacrylate 8 parts of ester, 2 parts of modified alkylphenol polyoxyethylene ether, 3 parts of nano-silica modified by silane coupling agent KH550, 8 parts of dimethacrylate modified polyethylene glycol (200), azobis 2 parts of isobutyronitrile, 0.08 parts of 2,5-di-tert-butylhydroquinone. The specific steps are as follows:

[0034] (1) Add stearyl methacrylate, triethylene glycol dimethacrylate, glycerol trimethacrylate, modified alkylphenol polyoxyethylene ether, modified nano-silica, modified Polyethylene glycol, 2,5-di-tert-butylhydroquinone, stirring speed 300-600 rpm, stirring for 10-30 minutes;

[0035] (2) Add azobisisobutyronitrile, stir at a speed of 600-800 rpm, and stir for 20-40 minutes;

[0036](3) Stand for 10-60 minutes.

[0037] The physical properties of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com