DMD (Dacron/Mylar/Dacron) flexible composite material adhesive

A technology of composite materials and adhesives, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of large internal stress, impact resistance, poor crack resistance and heat and humidity resistance, shrinkage Low problems, to achieve the effect of excellent bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of DMD soft composite material adhesive provided by the invention comprises the following steps:

[0038] Step 1: adding epoxy resin, phenolic resin and polyurethane resin to acetone and mixing, stirring evenly to obtain a mixed resin solution;

[0039] Step 2: Add the curing agent and the accelerator into the mixed resin solution, and stir evenly to obtain the adhesive.

[0040] The consumption of described acetone is 2-5 times of epoxy resin consumption.

Embodiment 1

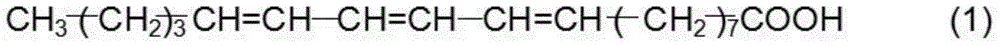

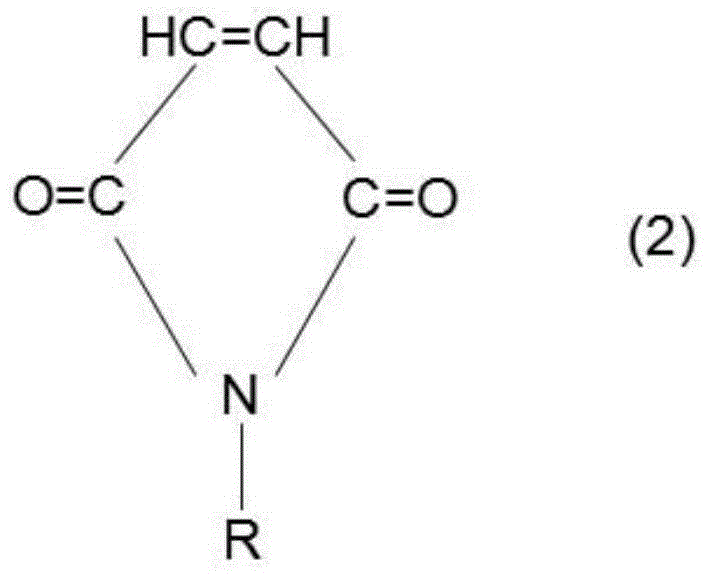

[0042] Preparation of curing agent: Add 120 parts by weight of dry vegetable oil and 60 parts by weight of imine monomer into the reaction kettle, heat it with microwave to 100°C, stir and react for 3 hours, add 30 parts by weight of maleic anhydride, and stir and react at 150°C After 5 hours, a curing agent was obtained.

[0043] Preparation of the adhesive: 35 parts by weight of polyphenol glycidyl ether epoxy resin, 10.5 parts by weight of phenol-formaldehyde resin and 22.5 parts by weight of polyurethane resin were mixed in 70 parts by weight of acetone, and stirred evenly to obtain a mixed resin solution; Add the curing agent in parts by weight and the triethanolamine accelerator in 2 parts by weight into the mixed resin solution, and stir evenly to obtain the adhesive.

Embodiment 2

[0045] Preparation of curing agent: Add 100 parts by weight of dry vegetable oil and 50 parts by weight of imine monomer into the reaction kettle, heat it with microwave to 150°C, stir and react for 5 hours, add 40 parts by weight of maleic anhydride, stir and react at 180°C After 4 hours, a curing agent was obtained.

[0046] Preparation of adhesive: Add 35 parts by weight of glycidylamine epoxy resin, 15 parts by weight of p-tert-butylphenol formaldehyde resin and 20 parts by weight of polyurethane resin into 140 parts by weight of acetone and mix them evenly to obtain a mixed resin solution ; Add 25 parts by weight of curing agent and 5 parts by weight of accelerator triethanolamine into the mixed resin solution, and stir evenly to obtain an adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com