Preparation method of PET polyester based on emulsion polymerization process

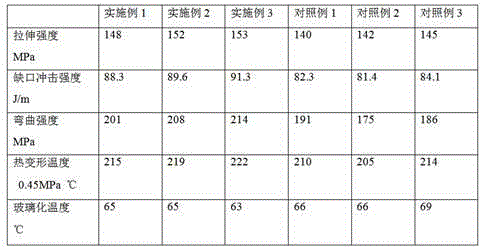

An emulsion polymerization method and emulsion polymerization technology are applied in the field of preparation of PET polyester, which can solve the problems of high glass transition temperature and poor mechanical strength of PET polyester, and achieve the effects of improving mechanical strength and reducing glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method based on the PET polyester of emulsion polymerization method may further comprise the steps:

[0027] Step 1. Preparation of polymer by emulsion polymerization: Add 90Kg of water and 2Kg of emulsifier into the reactor, stir evenly, then add 4Kg of acrylic acid, 4Kg of hydroxyethyl acrylate, and 5Kg of methyl methacrylate, stir evenly, and then add initiator Add 0.2Kg of agent, heat for polymerization reaction, then add 1Kg of iron trioxide, 10Kg of glass fiber, 4Kg of silicon oxide powder and stir evenly, obtain the polymer after suction filtration, wash the filter cake with ethanol, and dry the filter cake to obtain Prepolymer, the polymerization reaction temperature is 70°C, the polymerization reaction time is 1 hour, the initiator is potassium persulfate, the emulsifier is sodium dodecylbenzenesulfonate, and the length of the glass fiber is 10-500 microns ;

[0028] Step 2, prepolymer, polyethylene terephthalate 40Kg, butanediol diacrylate 3Kg...

Embodiment 2

[0032] The preparation method based on the PET polyester of emulsion polymerization method may further comprise the steps:

[0033] Step 1. Preparation of polymer by emulsion polymerization: Add 110Kg of water and 4Kg of emulsifier into the reactor, stir well, then add 6Kg of acrylic acid, 7Kg of hydroxyethyl acrylate, and 9Kg of methyl methacrylate, stir well, and then add trigger Add 0.4Kg of agent, heat for polymerization reaction, then add 2Kg of iron trioxide, 20Kg of glass fiber, 8Kg of silicon oxide powder and stir evenly, obtain the polymer after suction filtration, wash the filter cake with ethanol, and dry the filter cake to obtain Prepolymer, the polymerization reaction temperature is 80°C, the polymerization reaction time is 2 hours, the initiator is potassium persulfate, the emulsifier is sodium dodecylbenzenesulfonate, and the length of the glass fiber is 10-500 microns ;

[0034] The 2nd step, with prepolymer, polyethylene terephthalate 60Kg, butanediol diacryl...

Embodiment 3

[0038] The preparation method based on the PET polyester of emulsion polymerization method may further comprise the steps:

[0039] Step 1. Preparation of polymer by emulsion polymerization: Add 100Kg of water and 3Kg of emulsifier into the reactor, stir evenly, then add 5Kg of acrylic acid, 6Kg of hydroxyethyl acrylate, and 8Kg of methyl methacrylate, stir evenly, and then add initiator Add 0.3Kg of agent, heat to carry out polymerization reaction, then add 2Kg of iron trioxide, 15Kg of glass fiber, 6Kg of silicon oxide powder and stir evenly, obtain the polymer after suction filtration, then wash the filter cake with ethanol, after drying the filter cake, obtain Prepolymer, the polymerization reaction temperature is 75°C, the polymerization reaction time is 2 hours, the initiator is potassium persulfate, the emulsifier is sodium dodecylbenzenesulfonate, and the length of the glass fiber is 10-500 microns ;

[0040] Step 2, prepolymer, polyethylene terephthalate 50Kg, butane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com