Low-smoke halogen-free flame-retardant polyethylene cable material and preparation method thereof

A technology of flame-retardant polyethylene and cable materials, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem that the flame-retardant performance cannot meet market demand, and achieve good flame-retardant performance, broad application prospects, excellent durability The effect of heat aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

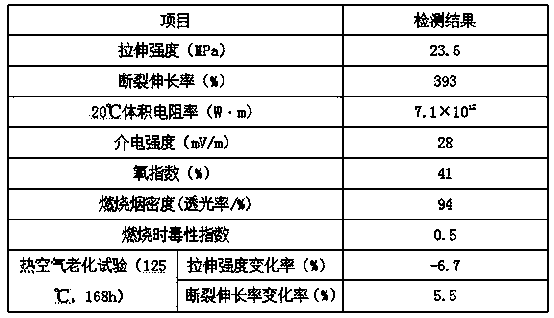

Examples

Embodiment

[0012] A low-smoke halogen-free flame-retardant polyethylene cable material, made of the following raw materials by weight (kg): medium density polyethylene 42, polyamide imide 30, diacetyl epoxy glycerin soybean oleate 8, antimony acid Sodium 6, bisphenol A polycarbonate 22, calcium stearate 3, ammonium metatungstate 8, benzyl benzoate 13, zinc ricinoleate 2.5, strong powder 18, toluene diphenyl phosphate 11, tin Magnesium acid 4.5, 2,5-di-tert-amyl hydroquinone 1.5, triethylene glycol methyl ether borate triester 10, flame retardant 12, bis(2,4-di-tert-butylphenyl) pentaerythritol diethylene Phosphate 2.5, cresyl trisiloxane 2;

[0013] The preparation method of the flame retardant is as follows: a, weigh boehmite, brucite, and montmorillonite in a ratio of 6:5:3 by mass, mix them evenly, pulverize them, pass through a 200-mesh sieve, and then add water to make an oar Concentration is 50% slurry, then add 5% ZnO, 27% NaOH and 21% Na 2 Sn(OH) 6 , heated to 75°C in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com