Self-repairing polyurethane coating and preparation method thereof

A polyurethane coating, self-healing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the complex preparation process of the microcapsule repair method, the influence of coating transparency and film formation, and the inability to achieve multiple repairs, etc. problems, to achieve the effect of easy control of the synthesis process, improved physical and mechanical properties, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

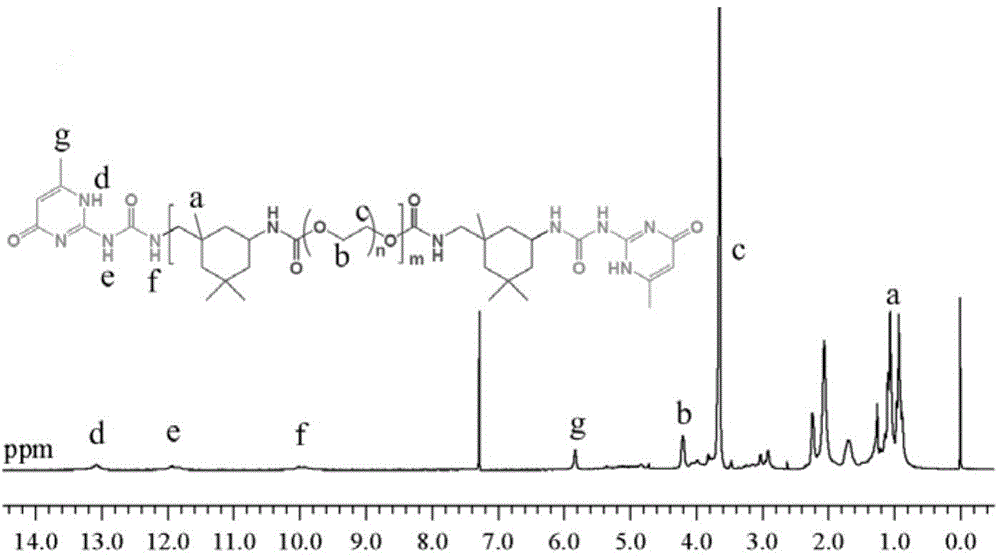

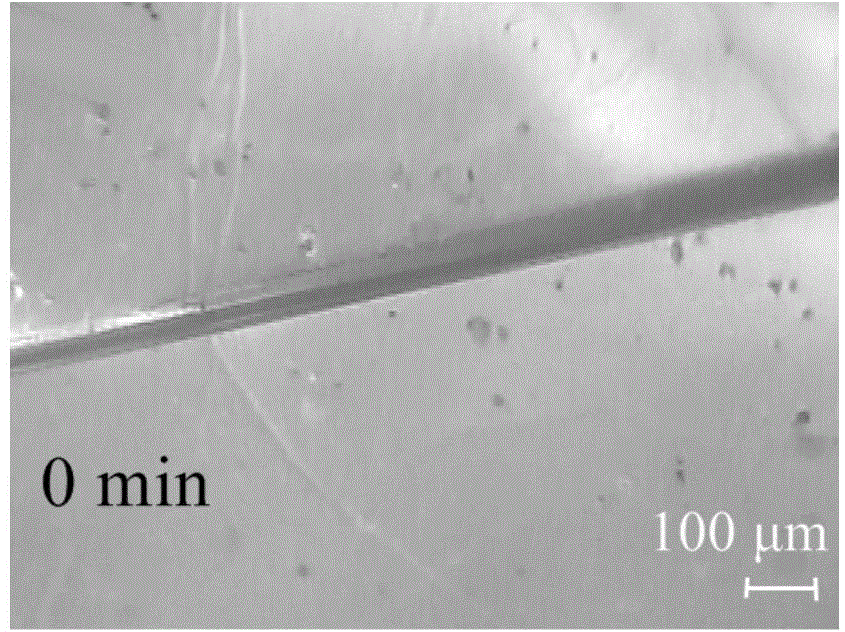

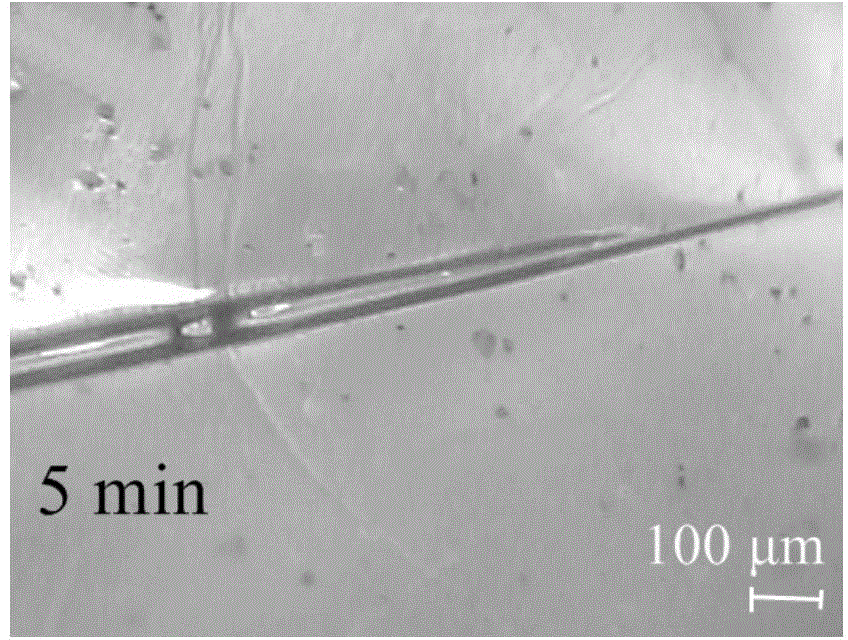

Method used

Image

Examples

Embodiment 1

[0035] Synthesis of hydrophilic polyurethane prepolymer: In terms of mass fraction, add 40 parts of polyethylene glycol and 3 parts of 1,4-butanediol chain extender into the Erlenmeyer flask, stir evenly, heat up to 120 ° C, and make Keep the vacuum degree of the reaction system above 0.08MPa. After dehydration for 3 hours, place it to lower the temperature to 60°C; then, add 15 parts of isophorone diisocyanate dropwise, and keep the reaction system at a temperature of 85°C The reaction was carried out for 3 hours, and the mass content of ─N═C═O in the prepolymer was determined by di-n-butylamine titration. When the actual measured value is close to the theoretical value, vacuum defoaming, sealed and stored for future use, the isocyanate group mass content of the hydrophilic polyurethane prepolymer is 3.5g / 100g, and the molar concentration is 0.0833mol / 100g;

[0036] Preparation of self-healing polyurethane coating: In terms of mass fraction, add 10 parts of MIC white powder a...

Embodiment 2

[0043] Synthesis of hydrophilic polyurethane prepolymer: Add 60 parts of hydrophilic polyether polyol, 1 part of 1,4-butanediol and 2 parts of trimethylolpropane chain extender into the Erlenmeyer flask, stir evenly, and heat up to 130°C, and keep the vacuum degree of the reaction system above 0.08MPa. After dehydration for 2 hours, place it to lower the temperature to 60°C; then, add 15 parts of isophorone diisocyanate dropwise, and let the reaction The system was reacted at a temperature of 85° C. for 2 hours, and the mass content of ─N═C═O in the prepolymer was determined by di-n-butylamine titration. When the actual measured value is close to the theoretical value, vacuum defoaming, sealed and stored for later use, the mass content of isocyanate group is 2.5g / 100g, and the molar concentration is 0.0595mol / 100g;

[0044] Preparation of self-healing polyurethane coating: Add 7 parts of MIC white powder and 100 mL of chloroform to a Erlenmeyer flask equipped with a mechanical...

Embodiment 3

[0047] Synthesis of hydrophilic polyurethane prepolymer: Add 40 parts of polyethylene glycol and 2 parts of 1,4-butanediol chain extender into the Erlenmeyer flask, stir evenly, heat up to 130°C, and make the vacuum of the reaction system Keep it above 0.08MPa, after dehydration for 2.5 hours, let it stand to lower the temperature to 60°C; then, add 20 parts of 1,6‐hexamethylene diisocyanate dropwise, and make the reaction system at a temperature of 80°C After reacting for 4 hours, the mass content of ─N═C═O in the prepolymer was measured by di-n-butylamine titration method. When the actual measured value is close to the theoretical value, vacuum defoaming, sealed and stored for later use, the mass content of isocyanate group is 4.0g / 100g, and the molar concentration is 0.0952mol / 100g;

[0048] Preparation of self-healing polyurethane coating: Add 10 parts of HMIC white powder and 100 parts of N,N‐dimethylformamide into a Erlenmeyer flask equipped with a mechanical stirring pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com