A kind of friction modifier containing graphene and preparation method thereof

A technology of friction modifier and nano-graphene, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of chemical corrosion wear, difficulty, blockage of filter oil supply, etc., and achieve stable chemical properties and excellent self-lubrication performance and reduce the wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

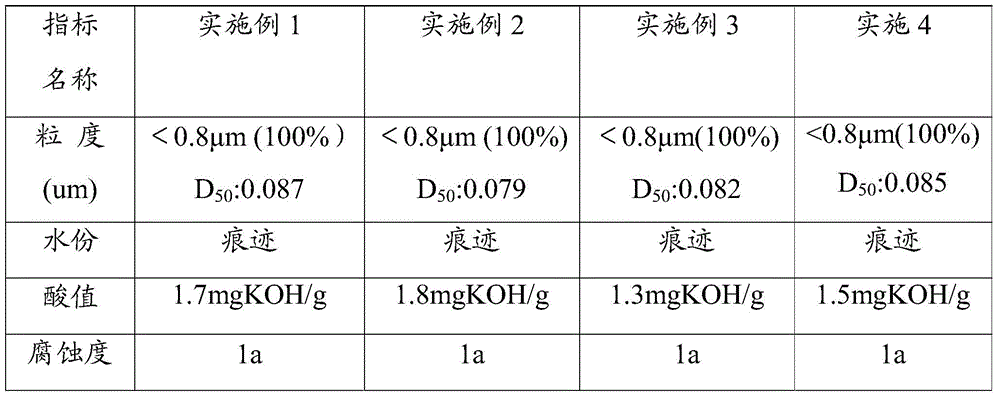

Examples

Embodiment 1

[0050] A friction modifier containing graphene, which is prepared from the following raw materials in mass percent:

[0051] Nanographene: 0.3%;

[0052] Nano graphite particles: 3%;

[0053] Ethylene-propylene copolymer 0.5%:

[0054] Bis-succinimide: 3.5%;

[0055] Base Oil: 95%

[0056] Specific steps are as follows:

[0057] 1) Preparation of nano-graphite particles

[0058]Abrasive preparation: 20% of graphite powder, 0.1% of cellulose, 0.5% of sodium methylene bis-naphthalene sulfonate, 0.5% of 25% ammonia water, and the balance of pure water in mass percent;

[0059] Crushing: the above-mentioned abrasives are ground and pulverized in a horizontal sand mill;

[0060] Classification: the above-mentioned graphite powder is classified by high-speed centrifugation at a speed of 5000 rpm;

[0061] Purification: add hydrochloric acid to the above-mentioned classified graphite powder to purify and condense, and adjust the pH to 2.3, press filter after condensing, and ob...

Embodiment 2

[0068] A friction modifier containing graphene, which is prepared from the following raw materials in mass percent:

[0069] Nano graphene: 0.5 parts

[0070] Nano graphite particles: 5 parts

[0071] Styrene-diene copolymer: 1%

[0072] Succinate / Benzylamine: 2%

[0073] Base oil: balance;

[0074] Specific steps are as follows:

[0075] 1) Preparation of nano-graphite particles

[0076] Abrasive preparation: 25% of graphite powder, 0.3% of cellulose, 0.2% of sodium methylene bis-naphthalene sulfonate, 0.7% of 25% ammonia water, and the balance of pure water in mass percent;

[0077] Pulverization: the above-mentioned grinding material is circularly ground and pulverized by a horizontal sand mill; classification: the above-mentioned graphite powder is classified by high-speed centrifugation at a speed of 6000 rpm;

[0078] Purification: add hydrochloric acid to the above-mentioned classified graphite powder to purify and condense, and adjust the pH to 2.5, press filter ...

Embodiment 3

[0085] A friction modifier containing graphene, which is prepared from the following raw materials in mass percent:

[0086] Nanographene: 1%

[0087] Nano graphite particles: 5%

[0088] Cetyl-N-vinylpyrrolidone copolymer: 5%

[0089] Succinate: 3%

[0090] Base oil: balance;

[0091] The specific preparation method is carried out according to the steps of Example 1; in the grinding material preparation step, graphite powder 27.6%, cellulose 0.4%, sodium methylene bis-naphthalene sulfonate 0.3%, 25% ammonia water 0.6%, pure The water balance; in the step of dispersing and degumming, it is calculated by weight percentage: graphite filter cake: 29%, cellulose: 0.3%, polyvinyl alcohol: 0.2%, 25% ammonia water: 0.7%, pure water: the balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com