A kind of metal fiber electric brush and preparation method thereof

A metal fiber and fiber technology, applied in the field of electrical contact materials, can solve problems such as circuit short circuit, brush wear, system burnout, etc., and achieve the effects of small contact resistance, long service life, and large current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

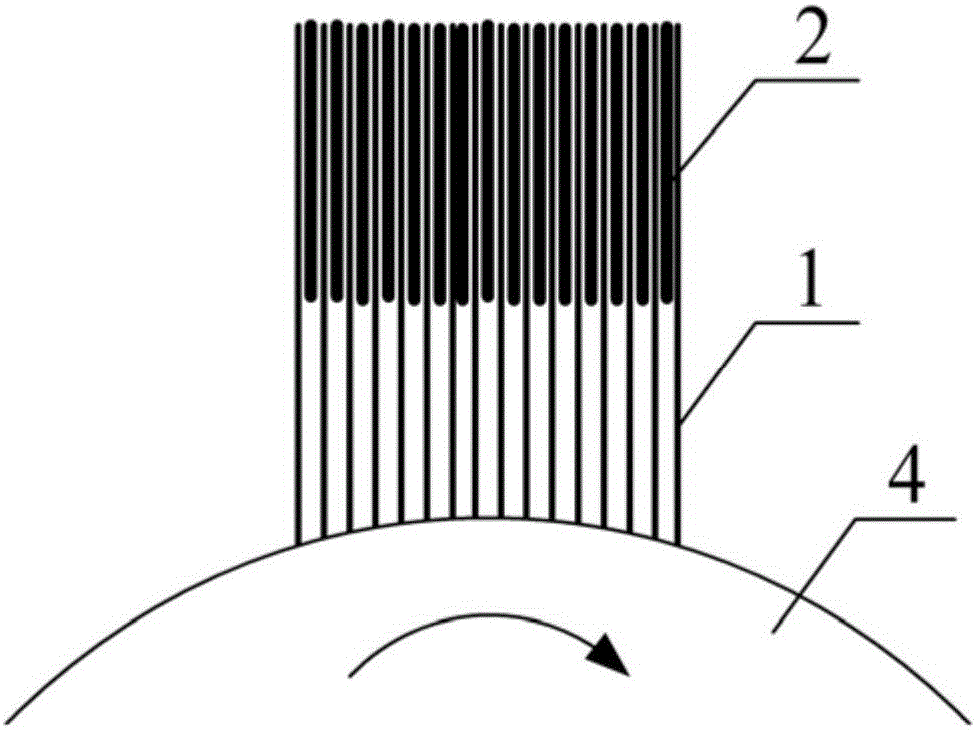

[0047] A method for preparing a metal fiber brush is achieved by adopting the following scheme:

[0048] The first step: 1 brass fiber with a diameter of 30 μm (Cu-20wt% Zn alloy fiber; conductive metal fiber) and 7 aluminum-magnesium alloy fibers with a diameter of 30 μm (Al-5wt% Mg alloy fiber; filled metal fiber) Winding together on the winding reel to obtain a metal fiber ring in which the brass fiber and the aluminum-magnesium alloy fiber are evenly matched;

[0049] Step 2: After the winding is completed, the metal fiber ring is cut to obtain a metal fiber bundle in which the brass fiber and the aluminum-magnesium alloy fiber are evenly matched;

[0050] The third step: press the metal fiber bundle obtained in the second step and wrap it with a metal sheath to obtain a metal fiber brush blank. Since the brush blank cannot be completely dense during pressing, the relative density of the prepared brush blank is relatively high. The density is about 85%; the pressure needs...

Embodiment 2

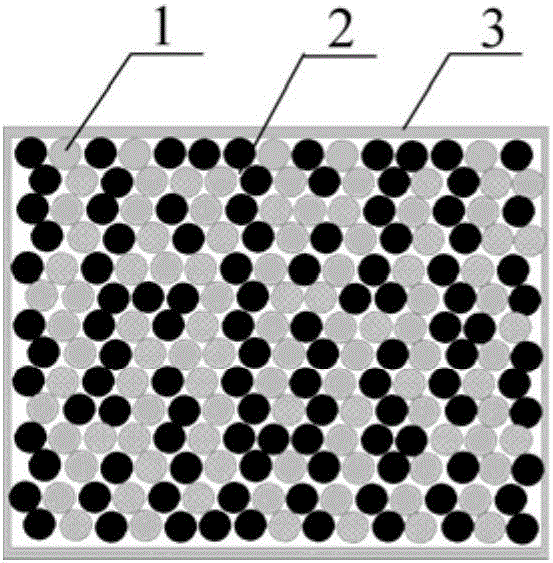

[0054] A method for preparing a metal fiber brush is achieved by adopting the following scheme:

[0055] The first step: a brass fiber (Cu-20wt% Zn alloy fiber; conductive metal fiber) with a diameter of 200 μm and an aluminum-magnesium alloy fiber (Al-5wt% Mg alloy fiber; filled metal fiber) with a diameter of 50 μm Winding together on the winding reel to obtain a metal fiber ring in which the brass fiber and the aluminum-magnesium alloy fiber are evenly matched;

[0056] Step 2: After the winding is completed, the metal fiber ring is cut to obtain a metal fiber bundle in which the brass fiber and the aluminum-magnesium alloy fiber are evenly matched;

[0057] The third step: Press the metal fiber bundle obtained in the second step and wrap it with a metal sheath to obtain a metal fiber brush blank. The relative density of the brush blank is about 85%. The pressure needs to be controlled during pressing to ensure a softer brush. The aluminum-magnesium alloy fiber has a certa...

Embodiment 3

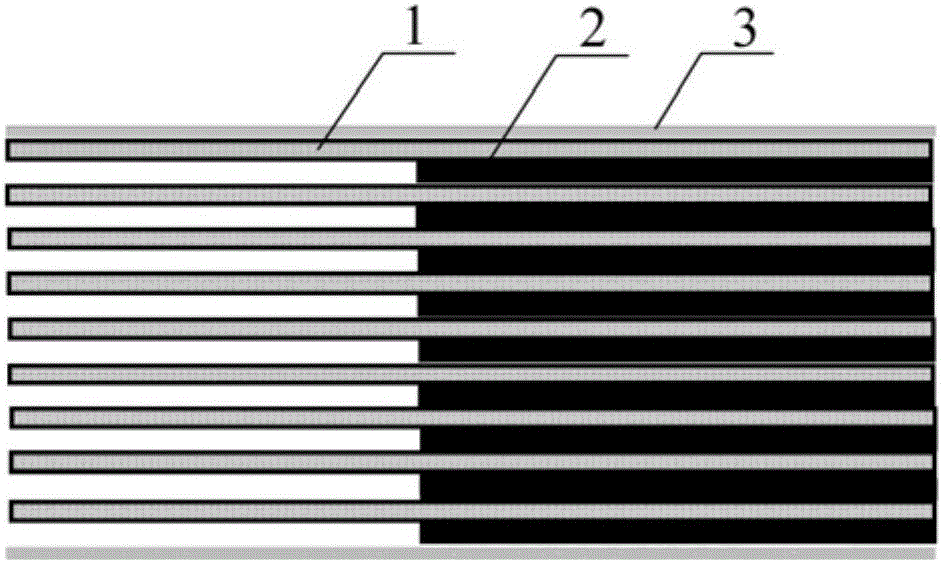

[0061] A method for preparing a metal fiber brush is achieved by adopting the following scheme:

[0062] The first step: 2 brass fibers with a diameter of 50 μm (Cu-20wt% Zn alloy fiber; conductive metal fiber) and 1 aluminum-magnesium alloy fiber with a diameter of 120 μm (Al-5wt% Mg alloy fiber; filled metal fiber) Winding together on the winding reel to obtain a metal fiber ring in which the brass fiber and the aluminum-magnesium alloy fiber are evenly matched;

[0063] Step 2: After the winding is completed, the metal fiber ring is cut off to obtain a metal fiber bundle in which the brass fiber and the aluminum-magnesium alloy fiber are evenly matched; the obtained metal fiber bundle is cut according to the length of the designed metal fiber brush, After obtaining multi-segment metal fiber bundles, arrange them uniformly along the length direction;

[0064] The third step: Press the metal fiber bundle obtained in the second step and wrap it with a metal sheath to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com