A kind of reinforced long spiral rock-socketed construction equipment and its technology

A construction equipment and enhanced technology, applied in drilling equipment, drilling equipment and methods, rotary drilling and other directions, can solve problems such as stuck drilling and immobility, and achieve small impact, enhanced drilling ability, and agitation and spraying. Pile uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

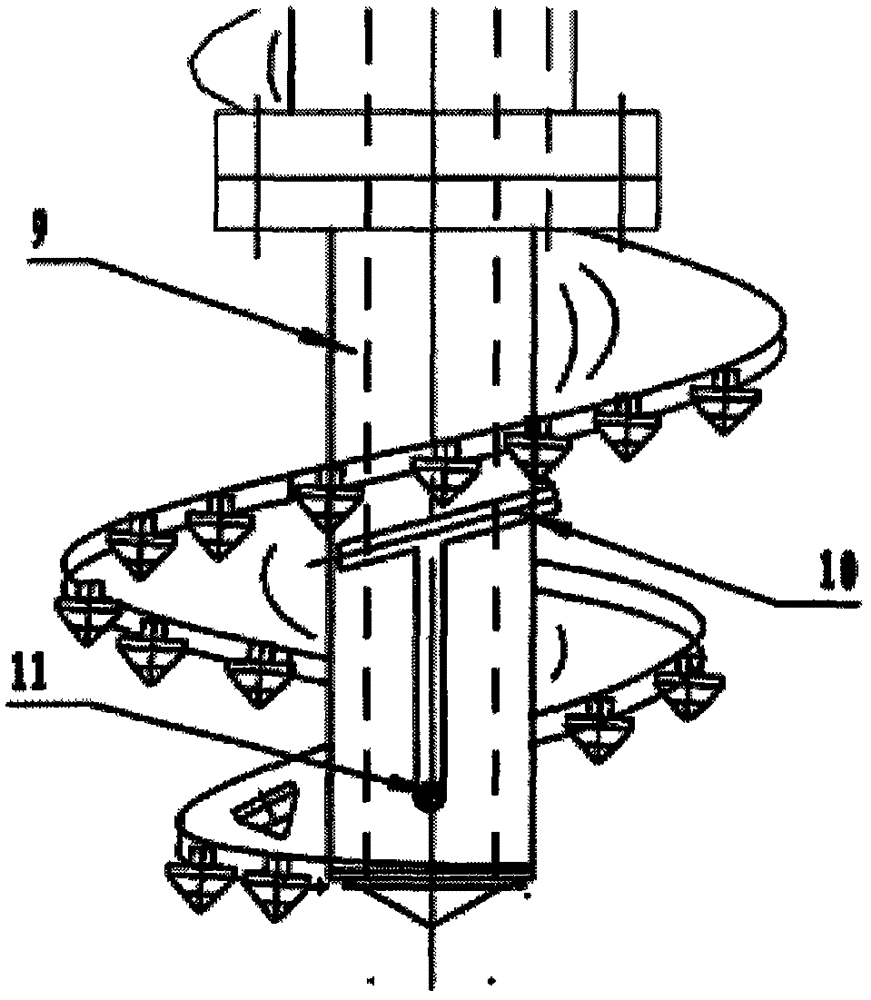

[0030] Fig. 2 is a schematic structural diagram of reinforced long spiral rock-socketed construction equipment, which consists of four parts: reinforced frame, power system, drilling system, and cooling system.

[0031] Among them, the power system is composed of power head (2), oil pressure output / inlet pipe (3), and power station (4). ), and connected with multifunctional flange (7) and reinforced drill pipe (8). When working, the power station inputs the oil pressure power into the power head through the oil pressure output / inlet pipe, and the drilling system is driven by the power bucket to drill into the hole, and the power is input to the motor on the pile frame to complete the lifting and lowering of the reinforced drill pipe . The torque provided by the power system is 150-210kN·m, and the drilling speed is 1.5-2.5m / min. The multifunctional flange can not only meet the requirements of normal concrete pouring, but also meet the requirements of cooling system grouting ...

Embodiment 2

[0035] Reinforced long spiral rock-socketed construction equipment consists of four parts: reinforced frame, power system, drilling system and cooling system.

[0036] Among them, the power system is composed of power head (2), oil pressure output / inlet pipe (3), and power station (4). ), and connected with multifunctional flange (7) and reinforced drill pipe (8). When working, the power station inputs the oil pressure power into the power head through the oil pressure output / inlet pipe, and the drilling system is driven by the power bucket to drill into the hole, and the power is input to the motor on the pile frame to complete the lifting and lowering of the reinforced drill pipe . The torque provided by the power system is above 230kN·m, and the drilling speed is 2.5-3.0m / min. The multifunctional flange can not only meet the requirements of normal concrete pouring, but also meet the requirements of cooling system grouting or water injection.

[0037] The drilling system ...

Embodiment 3

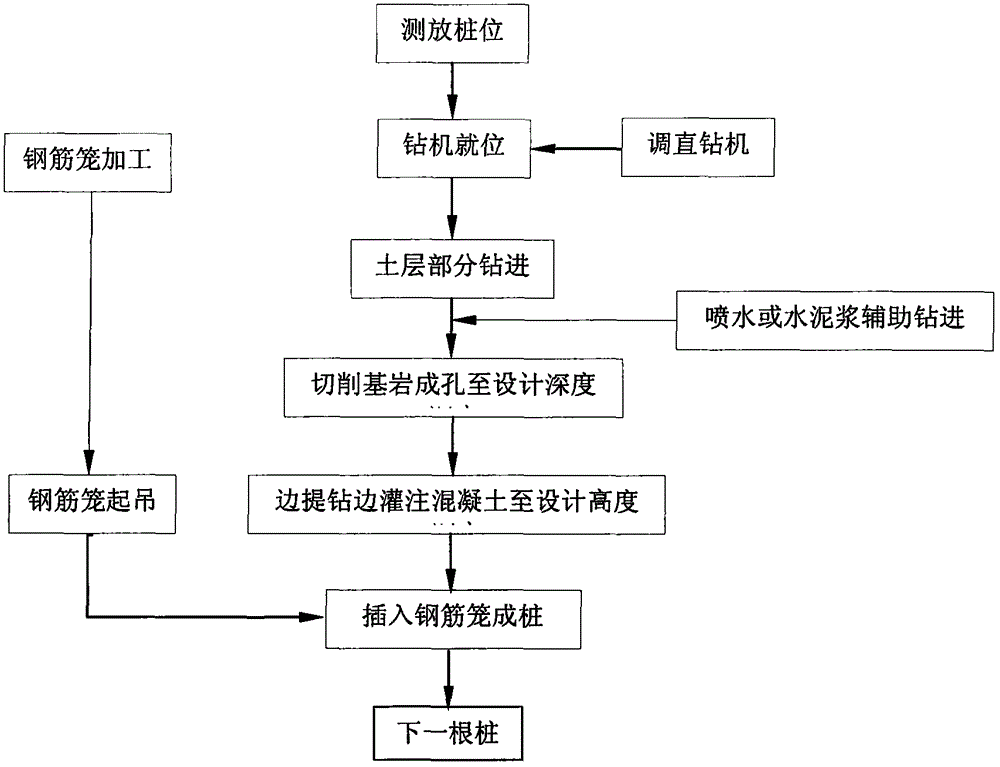

[0040] figure 1 It is a long spiral rock-socketed construction process flow chart. According to the process, it is explained as follows in conjunction with the following engineering example (a project in Hunan).

[0041] 1. Project overview

[0042] The high-rise building of Building 3# in a residential area, the structure type is a shear wall structure, with 44 floors above the ground and 1 floor underground. The foundation is planned to use pile foundation. The design elevation of the outdoor floor is 33.80m.

[0043] The design of this site adopts rock-socketed cast-in-place piles + post-grouting construction, the pile diameter is 800mm, the pile top elevation is 26.2m, the pile length is not less than 11m, and the pile end is required to enter the bearing layer⑦Strongly weathered slate is not less than 6.0m or stroke The argillaceous slate ⑧ is not less than 1.0m, and the characteristic value of the bearing capacity of a single pile is 4000KN.

[0044] 2. Engineering ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com