High wear resistance high chromium cast iron used for bimetallic composite tube and preparation method thereof

A technology of bimetal composite pipe and high chromium cast iron, which is applied in the field of wear-resistant metal materials, can solve problems such as poor wear resistance, and achieve the effects of improved wear resistance, high hardness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

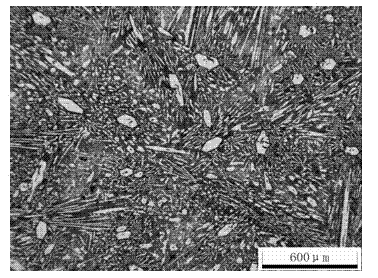

[0031] Embodiment 1: The high-wear-resistant high-chromium cast iron used in the bimetal composite pipe adopts the following composition ratio and preparation method.

[0032] The chemical composition is calculated by mass percentage: C 2.56%, Mn 1.0%, Si 2.5%, P 0.08%, S 0.04%, Cr 9.47%, V 0.10%, Ti 0.16%, and the balance is Fe and unavoidable impurities.

[0033]Preparation method: smelting in a 500kg intermediate frequency induction furnace and performing V and Ti alloying treatment. Before alloying treatment, add aluminum accounting for 0.30% of the qualified molten iron quality for deoxidation, and the furnace temperature is 1520°C; the furnace lining is acidic or basic. The proportioning, knotting, drying and sintering of the furnace lining are all carried out according to the conventional process. After being out of the furnace, the bimetallic composite pipe is made by centrifugal casting, and then heat treated. The specific process is: 980°C, heat preservation for 2 ho...

Embodiment 2

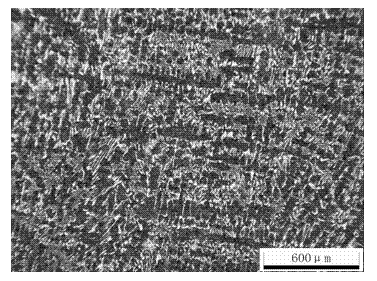

[0035] Embodiment 2: The high wear-resistant high-chromium cast iron adopts the following composition ratio and preparation method.

[0036] The chemical composition is calculated by mass percentage: C 3.25%, Mn 0.59%, Si 3.0%, P 0.065%, S 0.03%, Cr 11.37%, V 0.89%, Ti 0.20%, and the balance is Fe and unavoidable impurities.

[0037] Preparation method: adding 0.20% aluminum of qualified molten iron quality for deoxidation, the furnace temperature is 1500°C; the heat treatment process is: 960°C, heat preservation for 2.5h, air cooling; tempering temperature 400°C, heat preservation for 4h, air cooling; the rest is the same as in Example 1 .

[0038] The high chromium cast iron obtained in this example was tested according to relevant national standards, and the test results are shown in Table 1.

Embodiment 3

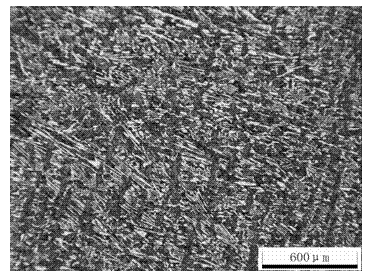

[0039] Embodiment 3: The high wear-resistant high-chromium cast iron adopts the following composition ratio and preparation method.

[0040] The chemical composition is calculated by mass percentage: C 2.70%, Mn 0.82%, Si 2.69%, P 0.059%, S 0.017%, Cr 12.13%, V 0.21%, Ti 0.15%, and the balance is Fe and unavoidable impurities.

[0041] Preparation method: adding 0.40% aluminum of qualified molten iron quality for deoxidation, the furnace temperature is 1540°C; the heat treatment process is: 970°C, heat preservation 3h, air cooling; tempering temperature 420°C, heat preservation 3.5h, air cooling; the rest is the same as in Example 1 .

[0042] The high chromium cast iron obtained in this example was tested according to relevant national standards, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com