Device for preparing ordered micro structure resin base composite material film

A composite material film and preparation device technology, applied in the direction of coating and the like, can solve the problems of not involving the preparation of thermoplastic resin-based composite materials, the narrow size range of the composite material, and the low preparation efficiency of the composite material, so as to achieve a large degree of design freedom and improve the Efficiency, the effect of increasing application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

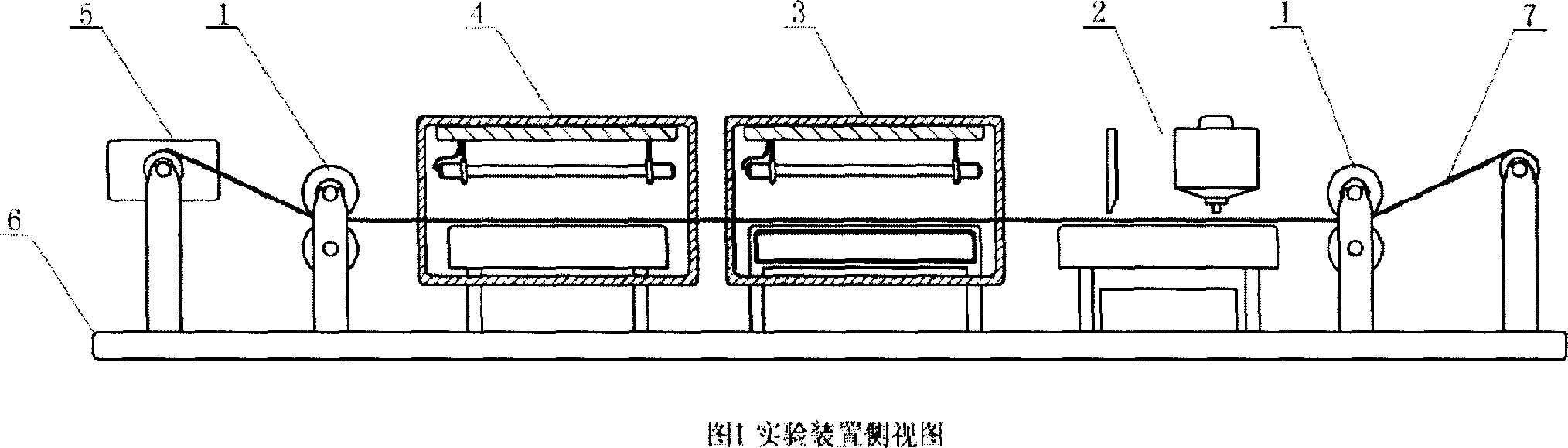

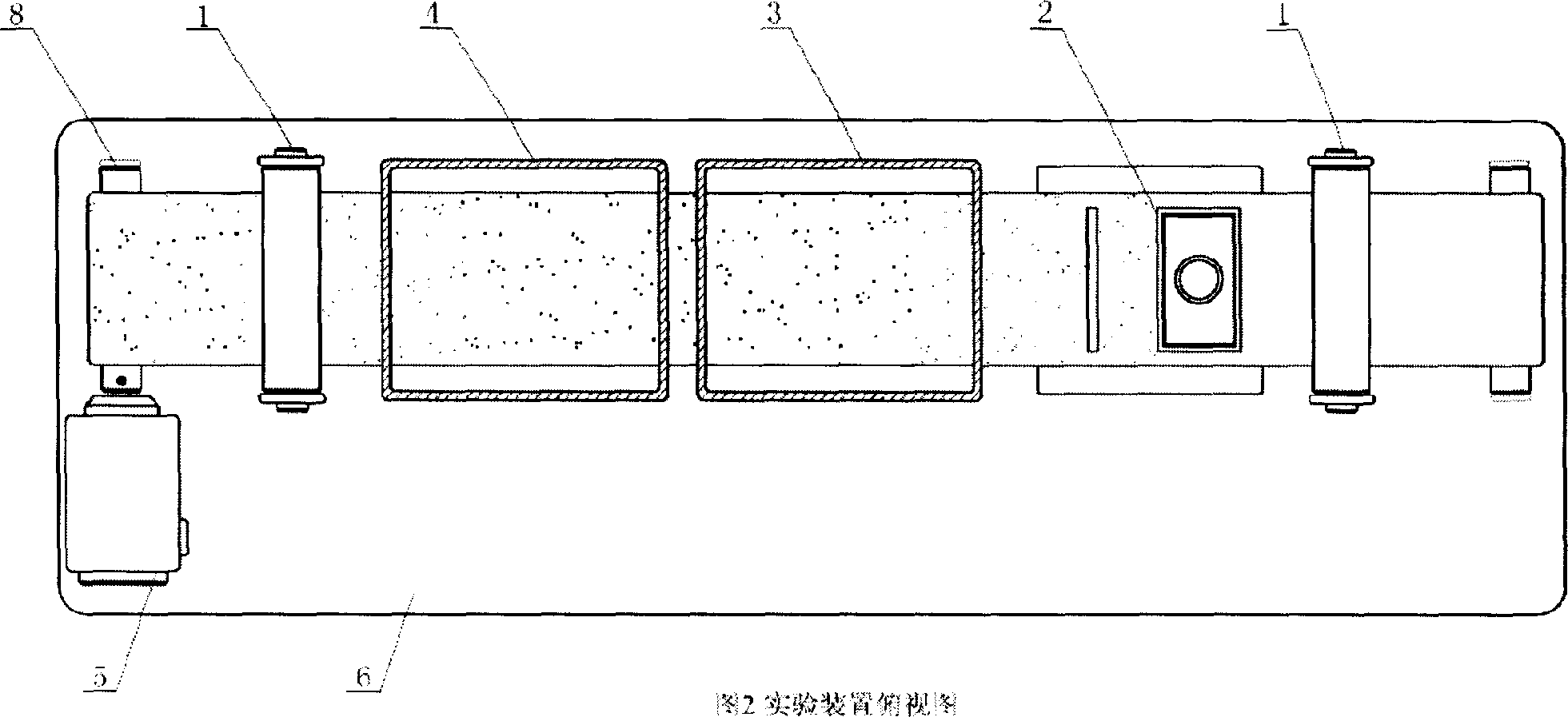

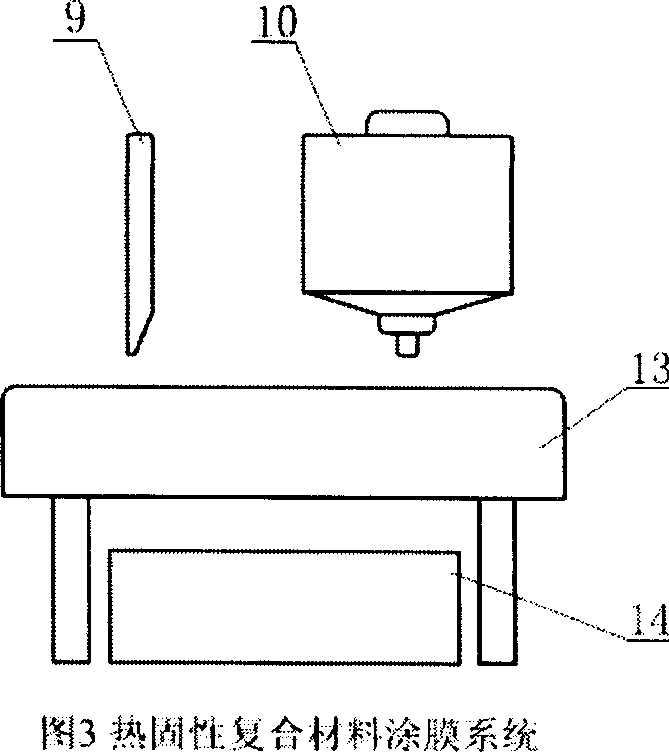

[0035] Weigh ferrite:epoxy resin:tetraethylenepentamine (curing agent) in a mass ratio of 1:10:2, mix, then ultrasonically disperse, and vacuum degas to obtain a ferrite / epoxy resin composite material liquid. The liquid is introduced into the thermosetting composite raw material casting extrusion groove in the coating system, and the composite material is extruded and coated on the base film. Start the DC servo motor with a speed of 2r / min, the motor drives the bottom film to move, adjust the height of the thickness control plate, and control the thickness of the composite film. When the composite material enters the magnetic field processing system, it is heated with a heating tube, and the temperature of the heating tube is controlled at about 40°C, so that the epoxy resin is gradually pre-cured during the process of ordering the ferrite. When the composite came out of the magnetic field, the epoxy crosslinked enough to hold the ordered ferrites in place. Then the composite...

Embodiment 2

[0037] Dissolve 5g of polyvinyl alcohol (PVA) with a polymerization degree of 1750 in 50ml of water at 85°C, add 1g of ferrite, stir, and then transfer the composite material solution to a thermoplastic raw material casting extrusion tank at a temperature of 85°C, At this point, heat the heating plate to 85°C, then extrude the composite material and coat it on the bottom film, start the DC servo motor at a speed of 2r / min, the motor drives the bottom film to move, adjust the height of the thickness control board, and control the thickness of the composite film . When the composite material enters the magnetic field treatment system, it is heated and dried with a heating tube, and the temperature is controlled at about 60°C, so that the composite material still has a certain fluidity, so that the ferrite can be well ordered in the magnetic field system. After the composite material comes out of the magnetic field, it is cooled and dried at room temperature, so that the ordered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com