Preparation method of reactive brilliant blue K-GR intermediate

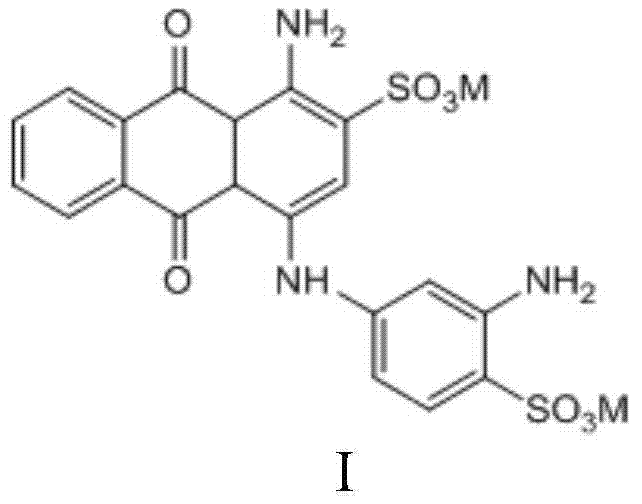

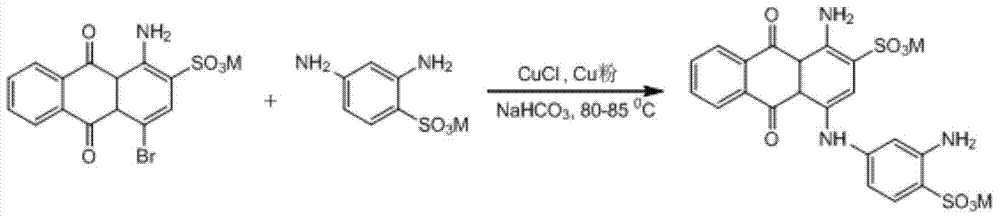

A technology of reactive brilliant blue and intermediates, which is applied in the preparation of sulfonates, chemical instruments and methods, anthracene dyes, etc., can solve the problems of reducing the amount of catalyst used, incomplete conversion of bromoamino acid, and reducing bicondensate, etc. The effect of reducing heavy metal content, improving yield, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

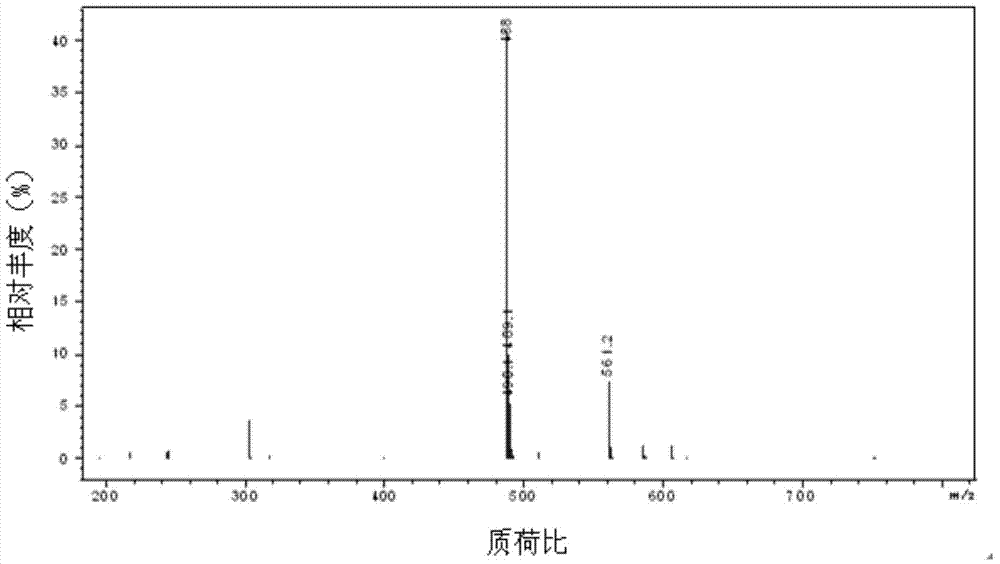

Method used

Image

Examples

Embodiment 1

[0042] Weigh 8.4 grams of sodium 2,4-diaminobenzenesulfonate, 8.4 grams of sodium bicarbonate, and 20 milliliters of water, add them to a container equipped with a stirrer, a condenser and a thermometer, and heat to 80°C while stirring. Weigh respectively 8.08 grams of bromine, 15% mol (based on bromine) of monovalent copper and 1,4,7,10-tetraazacyclododecane-1,3-diene (C 8 h 18 N 4 ) complex aqueous solution. Alternately add solid bromine and monovalent copper complexes into the container within 1 hour, keep the reaction temperature at 80-82°C, the pH of the reaction system at 9, and stir for 3 hours; raise the reaction temperature to 85-90°C, Stir the reaction, take a sample for thin-layer chromatography and liquid chromatography analysis, and no bromidine is the end point of the reaction. In the reaction liquid mixture, there are no hydrolyzed products of bromoacidic acid (purple side) and bicondensates, but there are traces of debrominated products.

[0043] Cool the a...

Embodiment 2

[0045] Weigh 21 grams of 2,4-diaminobenzenesulfonic acid, 26.5 grams of sodium carbonate, and 50 milliliters of water, add them into a container equipped with a stirrer, a condenser, and a thermometer, and heat to 80°C while stirring. Weigh respectively 20.2 grams of bromine, 10% mol (based on bromine) of monovalent copper and 1,4,7,10-tetraazacyclododecane-1,3-diene (C 8 h 18 N 4 ) complex aqueous solution. Alternately add solid bromine and monovalent copper complexes into the container within 2.5 hours, keep the reaction temperature at 78-82°C, the pH of the reaction system at 8-9, stir for 3-5 hours; keep the reaction temperature at 80-90 ℃, stirring the reaction, sampling for thin-layer chromatography and liquid chromatography analysis, no bromidine as the reaction end point. In the reaction liquid mixture, there are no hydrolyzed products of bromoacidic acid (purple side) and bicondensates, but there are traces of debrominated products.

[0046] The above materials we...

Embodiment 3

[0048] Weigh 8.4 g of 2,4-diaminobenzenesulfonic acid, 8.4 g of sodium bicarbonate, and 20 ml of water, add them into a container equipped with a stirrer, a condenser, and a thermometer, and heat to 80°C while stirring. Weigh respectively 8.08 grams of bromine, 10% mol (based on bromine) of monovalent copper and 1,4,7,10-tetraazacyclododecane-1,3-diene (C 8 h 18 N 4 ) complex ethanol solution. Alternately add solid bromine and monovalent copper complexes into the container within 1 hour, keep the reaction temperature at 75-80°C, the pH of the reaction system at 8, stir for 3-4 hours; keep the reaction temperature at 85-90°C, Stir the reaction, take a sample for thin-layer chromatography and liquid chromatography analysis, and no bromidine is the end point of the reaction. In the reaction liquid mixture, there are no hydrolyzed products of bromoacidic acid (purple side) and bicondensates, but there are traces of debrominated products.

[0049] The above materials were coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com