Chemical agent capable of completely recycling power plant wastewater into circulating cooling water and preparation method of chemical agent

A technology for circulating cooling water and power plant wastewater, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as high operating costs, large heat consumption, and large investment, and achieve Does not require investment and does not increase the effect of facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The self-provided power plant of an enterprise in Ningxia fills the circulating water system with waste water, reverse osmosis concentrated water, and acid-base wastewater regenerated by ion exchange resins. The amount of water added per day is 50-100PPM), Cl - Reached 7682mg / l, 11 times as much as the national standard. The conductance is 21000us / cm, the hardness is 4263mg / l, and the alkalinity is 450mg / l. It has been running for half a year for a long time. During this period, the heat exchanger has been opened many times for inspection. Not only is there no scaling and corrosion, but the old scale has been removed. The membrane has been installed, and the zero discharge of the circulating water system has been realized.

Embodiment 2

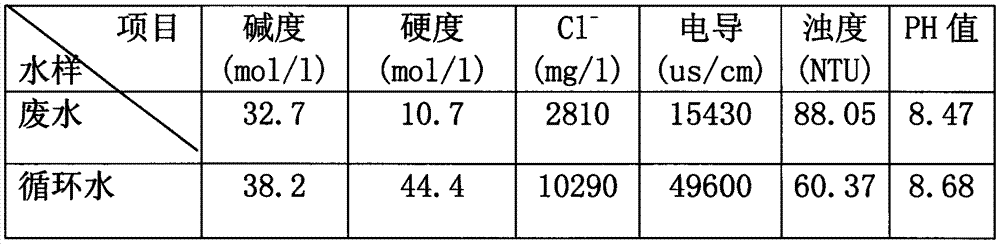

[0047]After adding the medicament of the present invention in the circulating water system of another enterprise's self-provided power plant in Ningxia (according to different water quality and the amount of water retained in the circulating water system, the amount added every day is 50-100PPM) the water quality on May 30, 2014 is:

[0048]

[0049] The circulating water system has not discharged a drop of water in the past six months of operation, and the equipment has no scale, corrosion, or mud, and calcium scale and rust scale have been removed.

Embodiment 3

[0051] There are two self-provided power plants of iron and steel enterprises in Handan. Desulfurization waste water, reverse osmosis concentrated water, ion exchange resin acid-base regeneration waste water are all used as supplementary water for circulating water. After adding medicament of the present invention in circulating water system (according to different water quality and the circulating water system retains water of 50-100PPM per day), and its wastewater quality is: alkalinity 8.5mmol / l, hardness 20mmol / l, Cl - 200mg / l, turbidity 60NTU. Industrial water is used when it is insufficient. Under the condition of zero discharge of circulating water, the equipment can operate safely for more than one year.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com