Utilization device for spiral internal air energy

A technology of air internal energy and exhaust device, applied in jet propulsion device, gas turbine device, machine/engine, etc., can solve the problem of limited effective enthalpy drop and thermal efficiency improvement, no major breakthrough in thermal engine efficiency, and can not reach the average heat absorption Problems such as temperature corresponding to pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

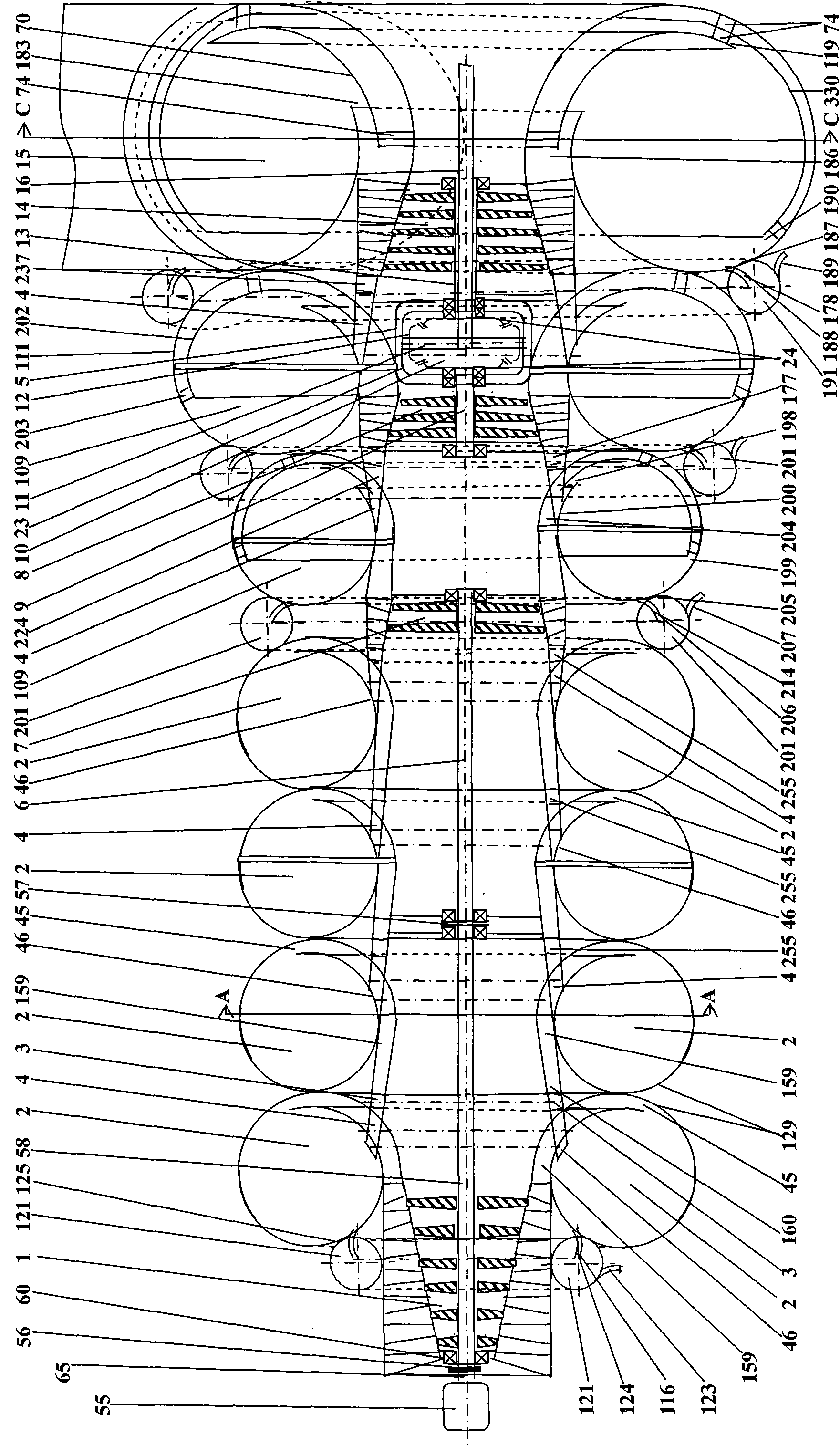

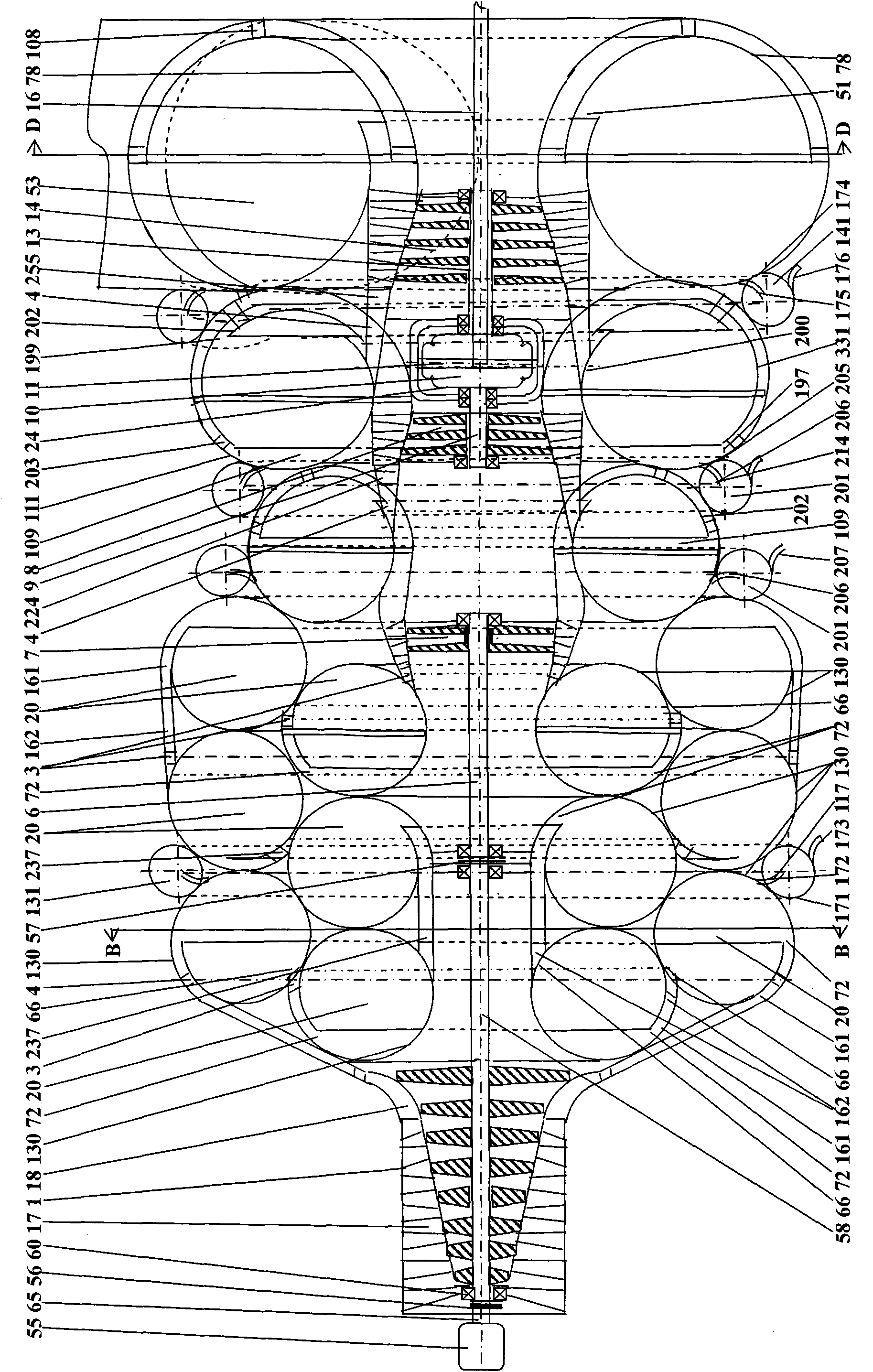

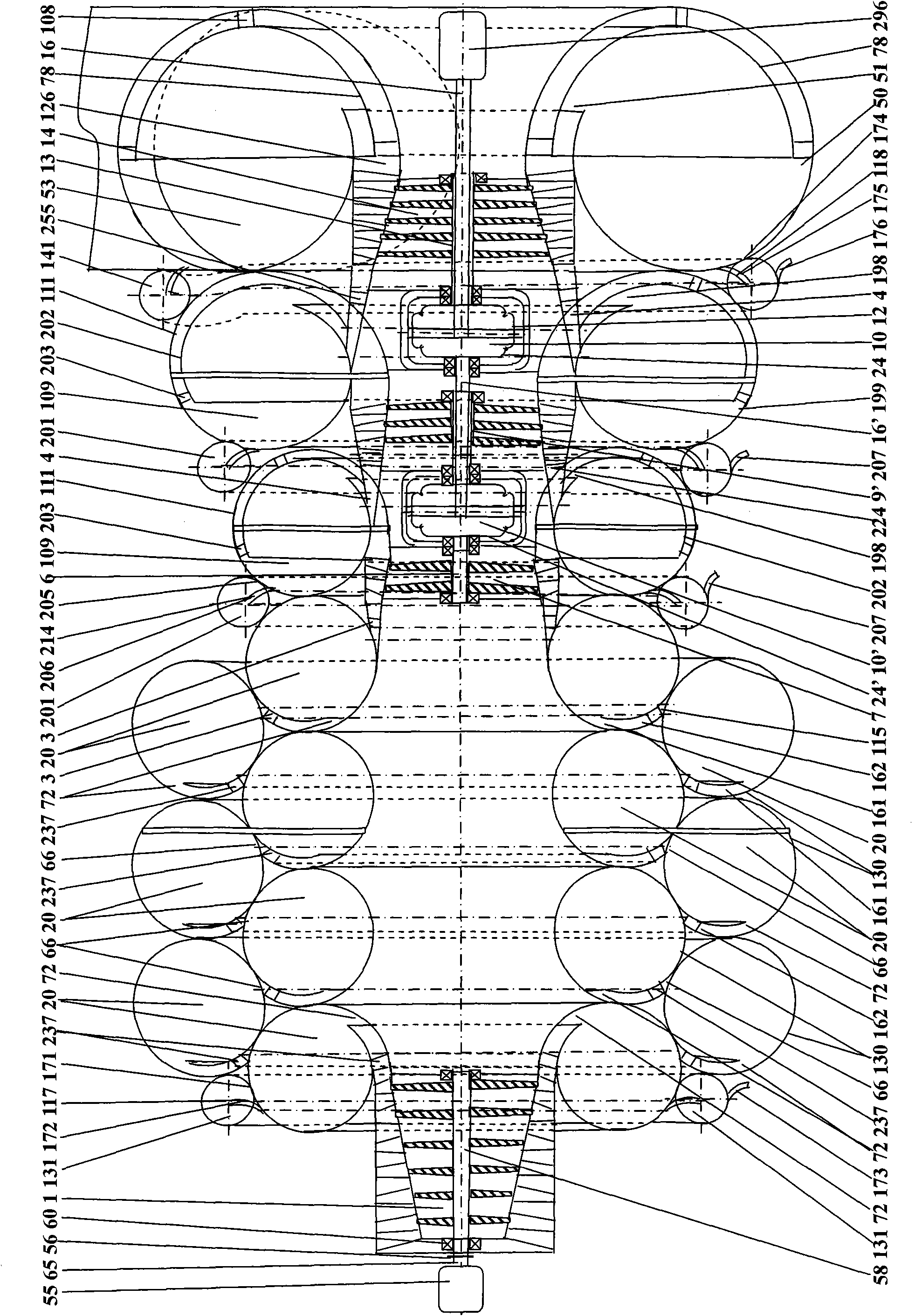

[0016] Specific implementation mode one, combining Figure 1 to Figure 27Describe this embodiment, the vortex air internal energy utilization device of this embodiment includes starter 55, starter clutch 56, compressor 1, ratchet type overrunning clutch 57, bushing type differential coupling, high pressure turbine 7, Medium-pressure turbine 8, low-pressure turbine 14 and computer control center; it is characterized in that: the energy utilization device in the vortex air also includes a vortex supercharger, a vortex exhaust device, a wedge control device; the vortex The turbocharger is composed of the first group of series-connected multi-stage scroll turbochargers arranged between the compressor 1 and the high-pressure turbine 7, and the second group of series-connected multi-stage turbochargers arranged between the high-pressure turbine 7 and the medium-pressure turbine 8. The scroll supercharger and the third group of series-connected multi-stage scroll superchargers arrang...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1 to Figure 4 , Figure 13 to Figure 15 Illustrate this specific embodiment, the wedge-shaped body regulating device of this specific embodiment is a one-position variant wedge-shaped body regulating device 224; Control device runner 226, at least three one-position variable wedge control device slideways 227 and the same number of one-position variable wedge control device rack chute 228, one-position variable wedge control device gear 229, one The gear shaft 230 of the position-variable wedge regulating device is composed of; the flow path 226 of the one-position variable wedge regulating device is a tapered or gradually expanding annular airflow passage, and at least three one-position variable wedge regulating device slides 227 are installed on On the inner wall of the channel 226 of the one-position variable wedge control device parallel to the axis, two adjacent one-position variable wedge control device slide...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 1 to Figure 4 , Figure 16 and Figure 17 Illustrate this specific embodiment, the wedge-shaped body regulating device of this specific embodiment is the extrapolation deformed wedge-shaped body regulating device 237; Extrapolation deformed wedge body 238, two first bar irons 244, at least two extrapolated deformed wedge regulating device gear shafts 243, at least four extrapolated deformed wedge regulating device gears 242 and the same number of outer The push-out deformation wedge control device rack chute 241 and the external push-out wedge control device slideway 240 are formed; each external push-out wedge 238 is made up of at least two strip-shaped elastic steel plates, and the two outer One end of the push-out deformed wedge 238 is fixedly installed on the corresponding two walls of the flow channel 239 of the push-out deformed wedge control device respectively, and the push-out deformed wedge control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com