Rotary type polluted soil thermal desorption experiment device and experiment method

An experimental device and thermal desorption technology, applied in the field of rotary contaminated soil thermal desorption experimental device, can solve the problems of inability to achieve thermal desorption, lack of broad-spectrum adaptability, etc., and achieve the effect of all-round control and parameter optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

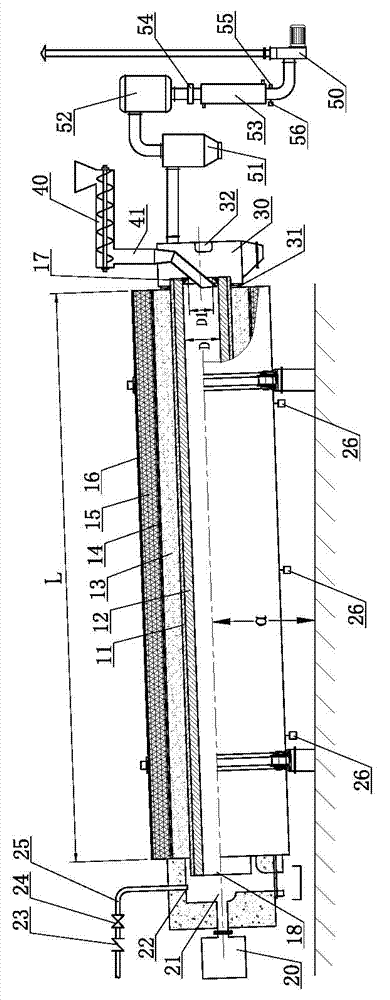

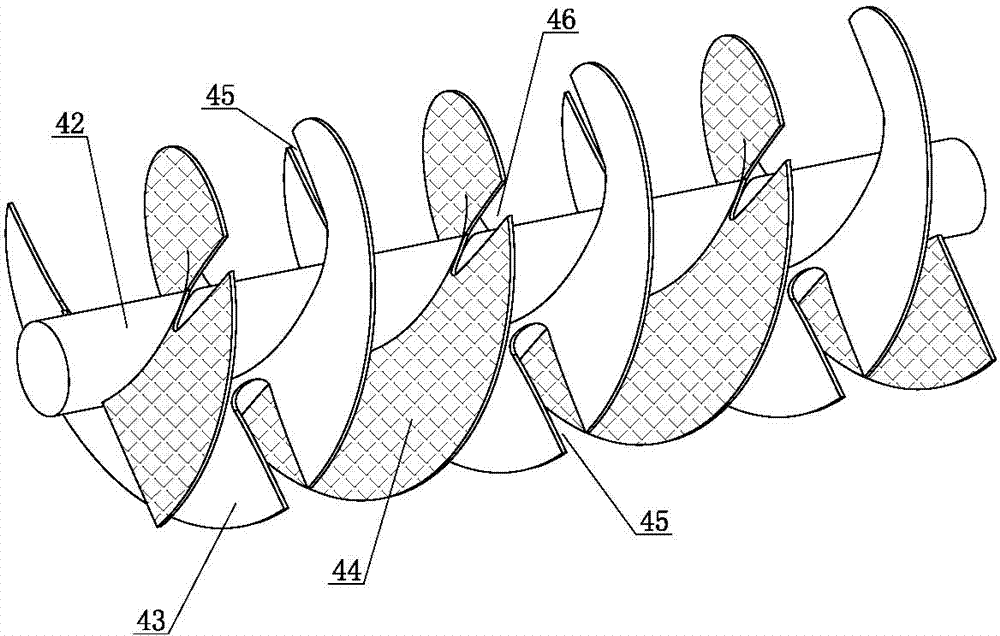

[0032] Such as figure 1 , figure 2 A rotary contaminated soil thermal analysis experimental device is used to collect gas generated by thermal analysis of organic polluted soil, including a rotary kiln for high temperature thermal analysis of contaminated soil, a feeding device, and a gas processing device.

[0033]The length of the rotary kiln cylinder is L=3200mm. The rotary kiln includes a corundum furnace tube 11, a layer of mullite refractory layer 12 is arranged inside the corundum furnace tube, and an inner layer of alumina fiber is coated outside the corundum furnace tube for heat preservation. Material 13, the inner layer of alumina fiber insulation material is coated with a stainless steel outer cylinder 14, the outer layer of stainless steel outer cylinder is coated with an outer layer of alumina fiber insulation material 15, and the outer layer of alumina fiber insulation material is The material is covered with a stainless steel jacket 16 . The rotary kiln is e...

Embodiment 2

[0070] An experimental method for thermal analysis of polluted soil, the polluted soil is determined by GC-MS to belong to the low-boiling-point organic matter polluted soil; the organic pollutants in the polluted soil contain 53.27 mg / kg of benzene, 12.88 mg / kg of toluene, and 6.45 mg / kg of others .

[0071]Adjust the inclination angle α of the rotary kiln to 3.5°, so that the time for the contaminated soil to pass through the rotary kiln is controlled at 30 minutes, even if the contaminated soil is kept at the temperature of the thermal analysis experiment for 30 minutes.

[0072] Air is input from the thermal analysis atmosphere gas input port of the combustion mixing chamber.

[0073] The contaminated soil is evenly fed into the rotary kiln through the feeder for thermal heating, and the heated contaminated soil is discharged from the discharge port of the rotary kiln.

[0074] 11 thermal analysis experiments were carried out on the polluted soil, and the thermal analysis...

Embodiment 3

[0079] An experimental method for thermal analysis of polluted soil. The polluted soil is determined by GC-MS to belong to the polluted soil of medium-boiling point organic substances; the polluted soil contains 49.15 mg / kg of fluorene, 19.8 mg / kg of pyrene, and 13.5 mg / kg of anthracene.

[0080] Adjust the inclination angle α of the rotary kiln to 3°, so that the time for the contaminated soil to pass through the rotary kiln is controlled at 30 minutes, even if the contaminated soil is kept at the temperature of the thermal analysis experiment for 30 minutes.

[0081] The thermal analysis atmosphere gas is input from the thermal analysis atmosphere gas input port of the combustion mixing chamber. The thermal analysis atmosphere gas contains 3.1% oxygen, 24.2% carbon dioxide, 7.8% water vapor, and the rest is nitrogen.

[0082] The contaminated soil is evenly fed into the rotary kiln through the feeder for thermal heating, and the heated contaminated soil is discharged from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com