NLDMOS device and manufacture method thereof

A manufacturing method and device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that the breakdown voltage is not easy to increase, and achieve the effect of increasing the conduction breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

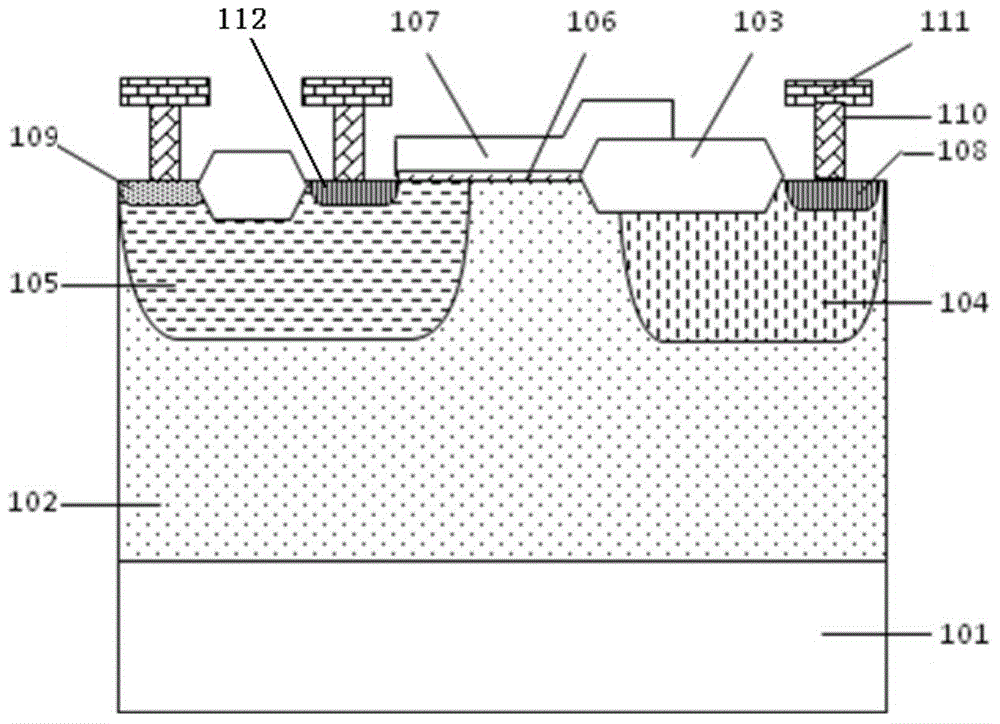

[0040] NLDMOS (N-type laterally diffused metal oxide semiconductor) devices, such as figure 2 As shown, an N-type deep well 102 is formed on the left part of the P-type silicon substrate 101;

[0041] A P well 105 is formed on the N-type deep well 102;

[0042] An N well 104 is formed on the right part of the P-type silicon substrate 101;

[0043] There is a P-type silicon substrate 101 spacer between the N-type deep well 102 and the N-well 104;

[0044] The P well 105 has a channel region field oxygen 114 formed in the middle;

[0045] A heavily doped P-type region 109 is formed on the P well 105 on the left side of the field oxygen 114 in the channel region, and a heavily doped N-type region 112 is formed on the P well 105 on the right side of the field oxygen in the channel region;

[0046] A drift region field oxygen 103 is formed in the middle of the N well 104; a heavily doped N-type region 108 is formed on the N well 104 on the right side of the drift region field o...

Embodiment 2

[0057] The manufacturing method of the NLDMOS device of Embodiment 1 mainly includes the following process steps:

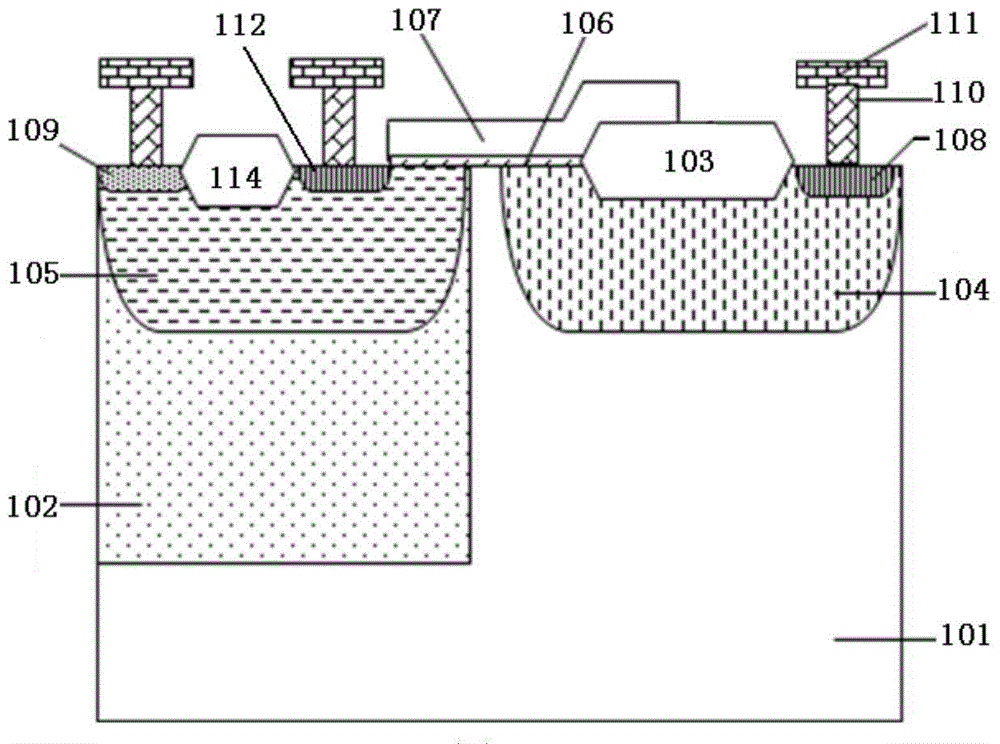

[0058] 1. On the left part of the P-type substrate 101, an N-type deep well 102 is formed by N-type ion implantation, such as image 3 shown;

[0059] 2. Utilize photolithography in the active region to open the field oxygen region, etch the field oxygen region, grow the field oxygen, form the field oxygen 114 in the channel region on the N-type deep well 102, and form the drift on the right part of the P-type substrate 101 Field Oxygen 103, such as Figure 4 shown;

[0060] 3. Photolithography opens the well implantation area, implants P-type impurity ions into the N-type deep well 102 below the channel region field oxygen 114 and its left and right sides to form a P well 105, and forms a P well 105 under the field oxygen 103 in the drift region and its left and right sides. N well 104 is formed by implanting N-type impurity ions into the P-type substrate 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com