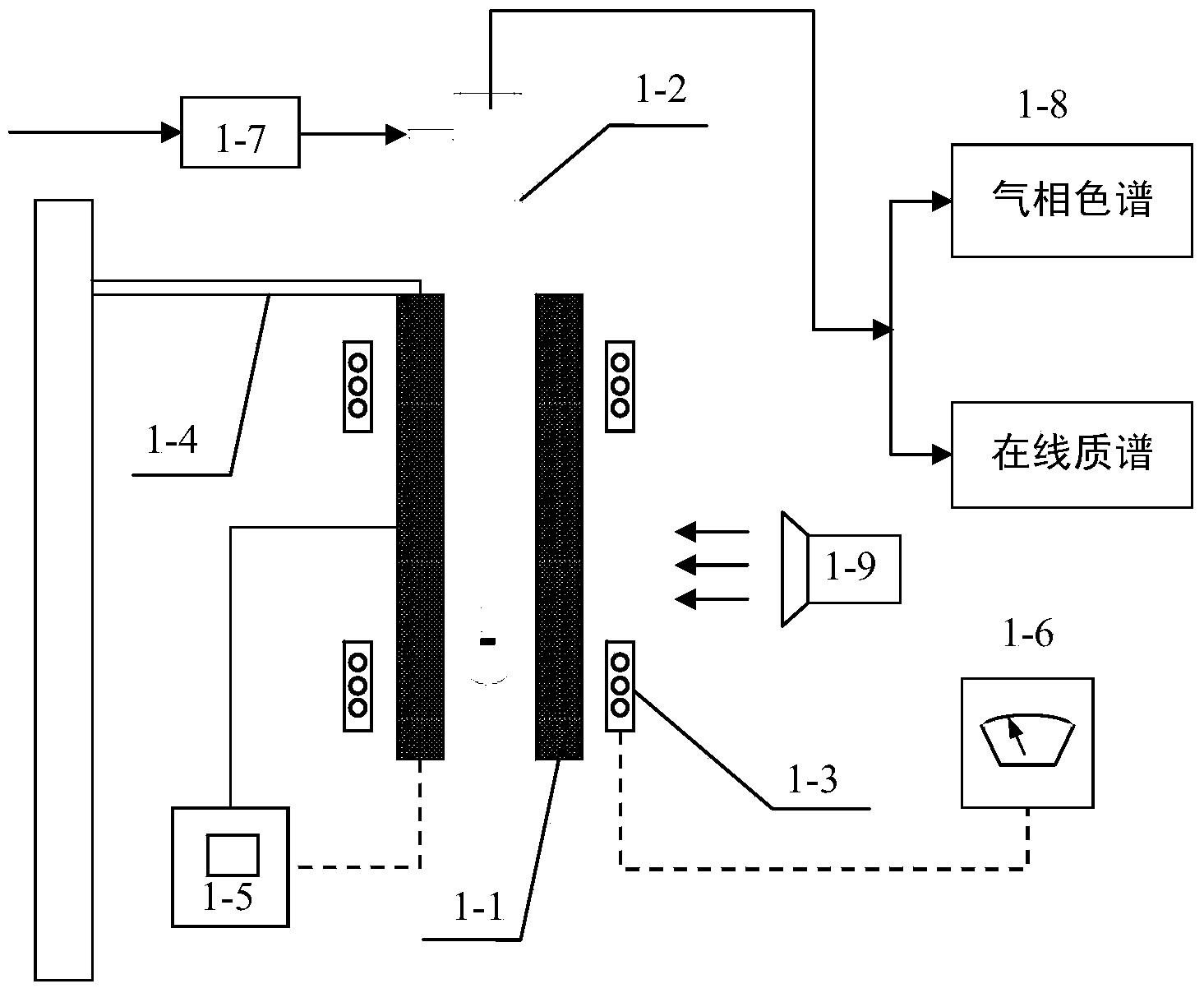

Visual fluidized bed reaction analysis system

A technology of fluidized bed reaction and fluidized bed reactor, which is applied in the field of visual fluidized bed reaction analysis system in the field of fluidization, can solve the problems of large furnace diameter, long distance between inner tube and outer tube, magnetic field coil weight and Volume increase and other problems, to achieve the effect of simple and flexible structure, enhanced fluidization performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

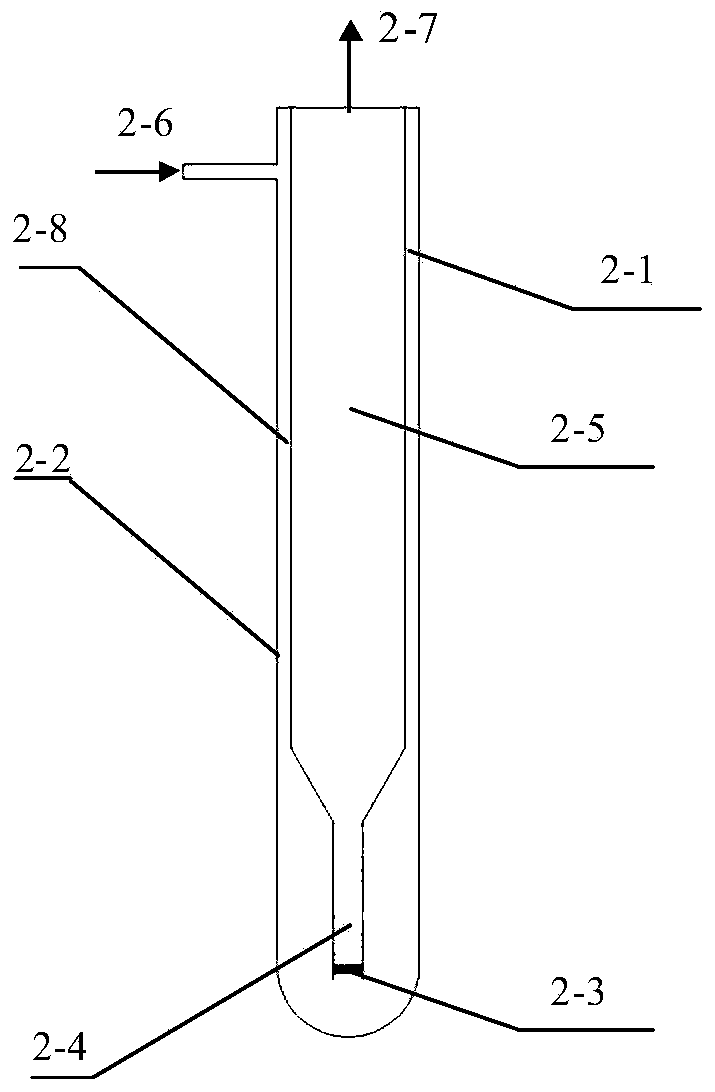

[0076] Taking the methane-carbon dioxide reforming reaction process as an example, the specific implementation of the visualized fluidized bed reaction analysis system of the present invention is further described.

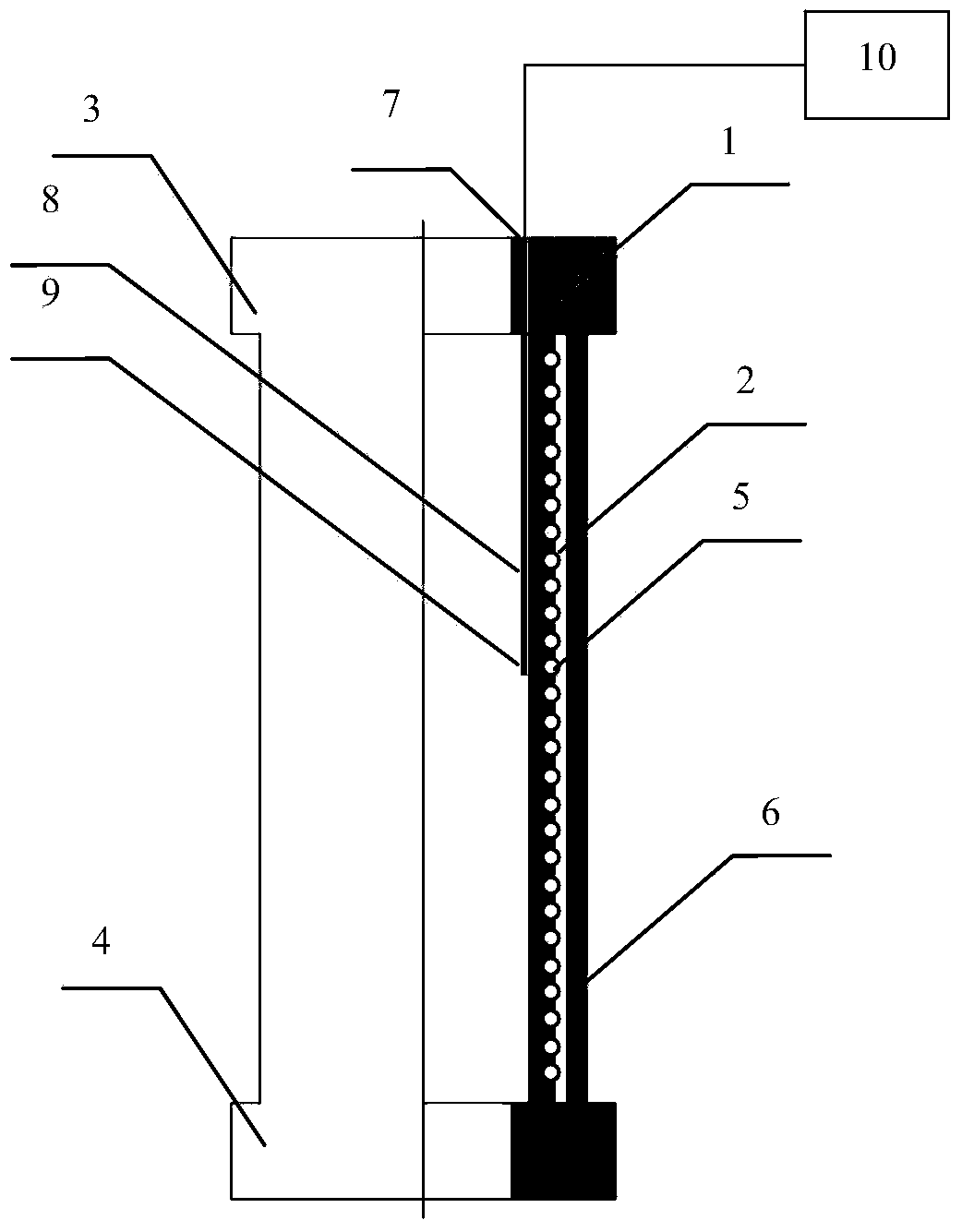

[0077] In this embodiment, a film-coated visible heating furnace with an observation window is used as a heating device for methane-carbon dioxide reforming reaction. The outer wall of the inner tube of the visualization heating furnace is provided with a spiral groove. The heating element is made of Cr20Ni80 high temperature resistant resistance wire with a diameter of 1.0 mm. The thermal insulation coating on the outer wall of the outer tube is a gold-plated coating with a thickness of 50 nm; Some are provided with observation windows without metal coating along the radial direction. The heating power of the heating furnace is 2000W, and the maximum heating temperature is 950°C.

[0078] The methane reforming catalyst used is Ni-Co-Al 2 o 3 Bimetallic catalys...

Embodiment 2

[0081] Taking the carbon monoxide methanation reaction as an example, the specific implementation of the visualized fluidized bed reaction analysis system of the present invention is further described.

[0082] In this embodiment, a coating visible heating furnace with an observation window is used as a heating device for the carbon monoxide methanation reaction. The outer wall of the inner tube of the visualization heating furnace is provided with spiral grooves. The heating element is Cr20Ni80 high temperature resistant resistance wire with a diameter of 1.0mm. The thermal insulation coating on the outer wall of the outer tube is silver-plated coating with a thickness of 100nm. In the central part of the heating furnace, there is an observation window without metal coating along the axial direction. The heating power of the heating furnace is 500W, and the maximum heating temperature is 600°C.

[0083] The methanation catalyst used is Ni-Al 2 o 3 Catalyst (the mass fracti...

Embodiment 3

[0085] Taking hydrogen reduction of nanometer iron oxide as an example, the specific implementation of the visualized fluidized bed reaction analysis system of the present invention is further described.

[0086] In this embodiment, a visible heating furnace with a coating with an observation window is used as a heating device for the hydrogen reduction reaction of nanometer iron oxide. A support frame is provided on the outer wall of the inner tube, and there is a card slot on the support frame. The heating element is a silicon-molybdenum rod with a diameter of 5.0mm. The thermal insulation coating on the outer wall of the outer tube is a nickel-tungsten alloy coating with a thickness of 20nm. In the central part of the heating furnace, there is an observation window without metal coating along the radial direction. The heating power of the heating furnace is 4000W, and the maximum heating temperature is 1050°C.

[0087] The nanometer iron oxide used is the iron oxide powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com