Cold-hot impact three-stage coal breaking device and implementing method

A heat-cooling and coal-breaking technology, applied in safety devices, drilling equipment and methods, earthwork drilling, etc., can solve the problem of low efficiency of gas drainage drilling drilling operations, reduce the working efficiency of drilling fracturing operations, and increase the Gas and coal seam outburst risks, etc., to overcome drilling equipment failures and borehole collapse risks, reduce drilling costs and gas outburst risks, and avoid coal and rock stress instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

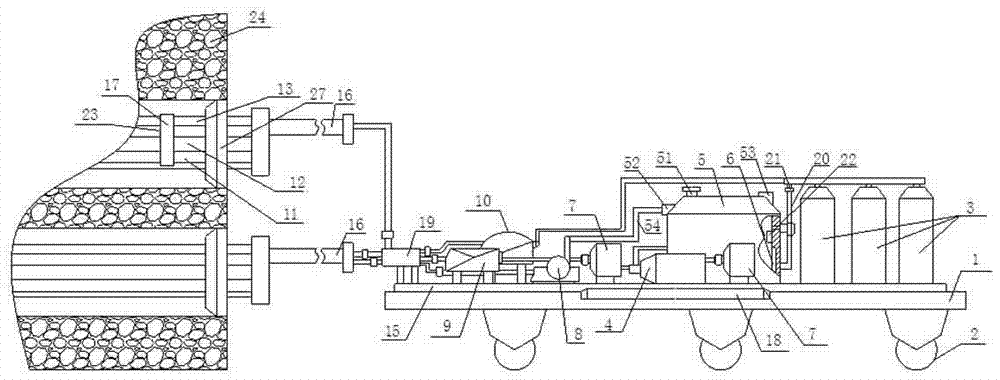

[0031] Such as image 3 As shown, a coal-breaking impact implementation method of a hot-cold impact three-stage coal-breaking device, which includes the following steps:

[0032] The first step, prefabricated drilling, at first, according to the needs of the design and mining operations, several drilling holes 23 are used on the coal seam. The spacing is 2-8 meters, and the drill holes 23 are distributed in an array structure, and the depth of the drill holes 23 is 1 / 15-1 / 10 of the design depth of the drill holes;

[0033] The second step is the prefabrication of the coal-breaking group. After the first step is completed, each coal-breaking group is connected to the jet pump 8, the jet fan 9, and the liquid nitrogen booster pump 10, and then the coal-breaking group is deep into the drill In the hole 23, the front end of the coal breaking unit is positioned by the elastic sealing plug 27 and the borehole 23 is sealed, so that the coal breaking unit and the borehole 23 are coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com