A method for modifying steel fibers in semi-metallic formula brake pads

A steel fiber and semi-metal technology, which is applied in the field of steel fiber modification in semi-metal formula brake pads, can solve problems such as adhesive wear, and achieve the effects of improving thermal decay, reducing wear rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

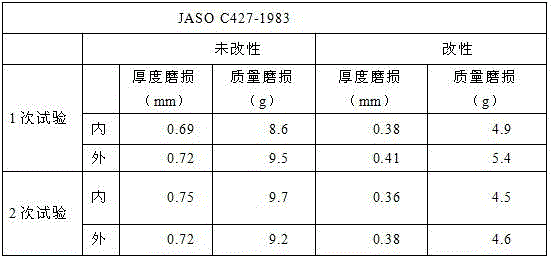

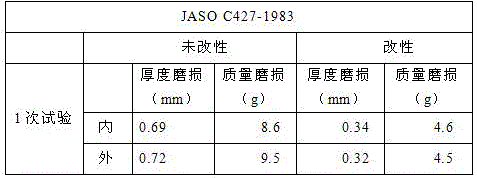

Examples

Embodiment 1

[0026] Step 1: Add water, Na 2 CO 3 Heating and stirring to dissolve, obtaining 200L of Na with a mass fraction of 4% 2 CO 3 solution, then slowly add 50kg of steel fiber into Na 2 CO 3 Stir in the solution to completely immerse the steel fibers in Na 2 CO 3 solution, keep Na 2 CO 3 The temperature of the solution is 40°C, soak for 15 minutes, take out the steel fiber after removing the grease on the surface of the steel fiber, and drain;

[0027]Step 2: Soak the steel fiber removed from the surface grease in step 1 in 200L piranha solution diluted 90 times with water for 20 minutes. The piranha solution is prepared by diluting concentrated sulfuric acid 100 times and diluting 10 times 30% hydrogen peroxide at a mass ratio of 4:1 , then remove the steel fibers and drain;

[0028] Step 3: Mix silane coupling agent, absolute ethanol, water, NaH 2 PO 4 , sodium tartrate and citric acid are put into the reaction container and mixed to obtain 100kg coupling agent soluti...

Embodiment 2

[0036] Step 1: Add water, Na 2 CO 3 Heating and stirring to dissolve, obtaining 200L of Na with a mass fraction of 4% 2 CO 3 solution, then slowly add 50kg of steel fiber into Na 2 CO 3 Stir in the solution to completely immerse the steel fibers in Na 2 CO 3 solution, keep Na 2 CO 3 The temperature of the solution is 40°C, soak for 15 minutes, take out the steel fiber after removing the grease on the surface of the steel fiber, and drain;

[0037] Step 2: Soak the steel fiber removed from the surface grease in step 1 in 200L piranha solution diluted 90 times with water for 20 minutes. The piranha solution is prepared by diluting concentrated sulfuric acid 100 times and diluting 10 times 30% hydrogen peroxide at a mass ratio of 4:1 , then remove the steel fibers and drain;

[0038] Step 3: Mix silane coupling agent, absolute ethanol, water, NaH 2 PO 4 , sodium tartrate and citric acid are put into the reaction container and mixed to obtain 100kg coupling agent solut...

Embodiment 3

[0045] Step 1: Add water, Na 2 CO 3 Heating and stirring to dissolve, obtaining 200L of Na with a mass fraction of 3% 2 CO 3 solution, then slowly add 50kg of steel fiber into Na 2 CO 3 Stir in the solution to completely immerse the steel fibers in Na 2 CO 3 solution, keep Na 2 CO 3 The temperature of the solution is 35°C, soak for 10 minutes, take out the steel fiber after removing the grease on the surface of the steel fiber, and drain;

[0046] Step 2: Soak the steel fiber removed from the surface grease in step 1 in 200L piranha solution diluted 80 times with water for 15 minutes. The piranha solution is prepared by diluting concentrated sulfuric acid 100 times and diluting 10 times 30% hydrogen peroxide at a mass ratio of 3:1 , then remove the steel fibers and drain;

[0047] Step 3: Mix silane coupling agent, ethanol, methanol, water, NaH 2 PO 4 , sodium tartrate and citric acid are put into the reaction container and mixed to obtain 100kg coupling agent solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com