Membrane dispersion extraction device and method for extracting and separating rear-earth elements by using device

An extraction device and membrane dispersion technology, which is applied in the direction of improving process efficiency, can solve the problem that the extraction and separation device cannot be industrialized, and achieve the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

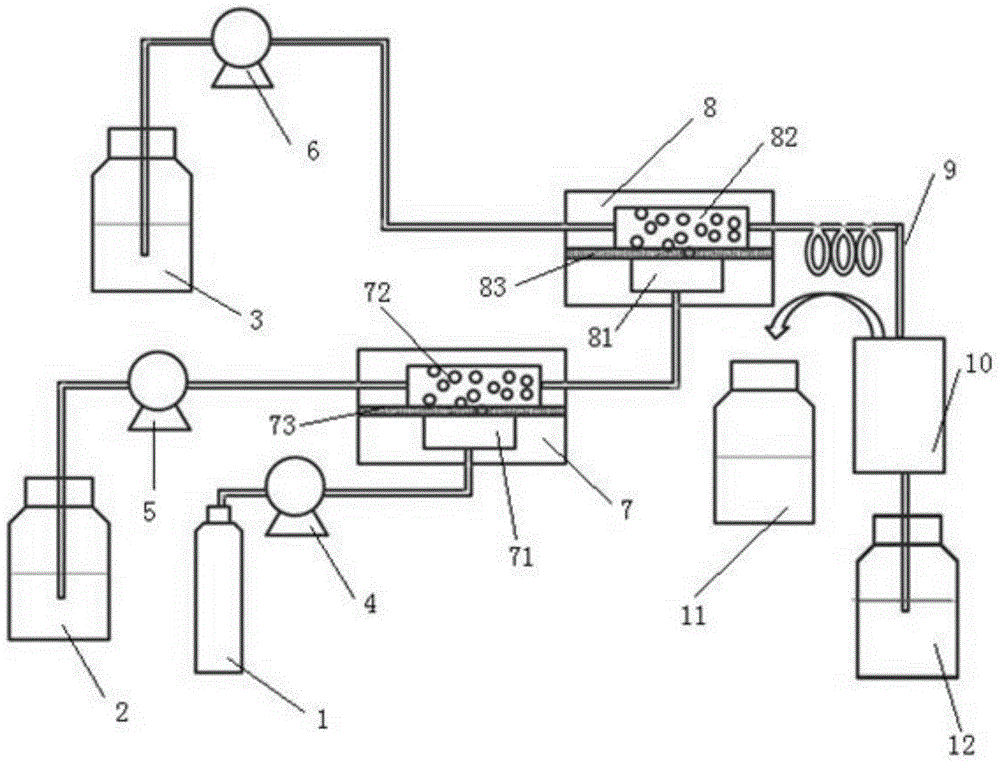

[0045] A kind of membrane dispersion extraction device described in this embodiment, such as figure 1 As shown, it includes: a bubble dispersed phase device 7, a gas-in-oil dispersed phase device 8 arranged in series with the bubble dispersed phase device 7; wherein, the bubble dispersed phase device 7 includes an air chamber 71 and an organic phase chamber 72, wherein , the gas-inflating chamber 71 is provided with a gas-phase delivery pipeline, and the gas-phase delivery pipeline is also connected with a gas delivery device. Controller 4; the organic phase chamber 72 is provided with an organic phase delivery pipeline, and the organic phase delivery pipeline is also connected with an organic phase delivery device. In this embodiment, the organic phase delivery device is sequentially connected The organic phase liquid reservoir 2 and the organic phase metering pump 5; the gas phase dispersion membrane 73 is arranged between the gas-filled chamber 71 and the organic phase cham...

Embodiment 2

[0050] (1) select nitrogen as the first dispersed phase;

[0051] (2) Prepare the first continuous phase: stir the concentrated ammonia water with a concentration of 26-28% and P507 with a purity of 92% at a volume ratio of 1:24 for saponification, and after a homogeneous phase is formed, a P507 solution with a degree of saponification of 20% is obtained , it is mixed with sulfonated kerosene in a volume ratio of 7.1:100 to prepare the P507 sulfonated kerosene solution of 0.2mol / L;

[0052] (3) Prepare the second continuous phase: add 0.46g LaCl to 1.0L, pH=2.0 hydrochloric acid solution 3 ·7H 2 O and 0.47g CeCl 3 ·7H 2 O, stir until completely dissolved;

[0053] (4) The parameters for selecting the gas-phase dispersion film are: the gas-phase dispersion film is a stainless steel sintered film with a pore size of 3 μm, a porosity of 70%, and a film thickness of 0.3 mm; the parameters for selecting the gas-in-oil dispersion film are: the oil-in-oil dispersion film The air...

Embodiment 3

[0056] (1) select compressed air as the first dispersed phase;

[0057] (2) Prepare the first continuous phase: stir the concentrated ammonia water with a concentration of 26-28% and P507 with a purity of 92% at a volume ratio of 1:16 for saponification. After a homogeneous phase is formed, a P507 solution with a saponification degree of 30% is obtained , it is mixed with sulfonated kerosene in a volume ratio of 10.6:100 to prepare the P507 sulfonated kerosene solution of 0.3mol / L;

[0058](3) Prepare the second continuous phase: add 0.56g LaCl to 1.0L, pH=3.0 hydrochloric acid solution 3 ·7H 2 O and 0.54g CeCl 3 ·7H 2 O, stir until completely dissolved;

[0059] (4) The parameters for selecting the gas-phase dispersion film are: the gas-phase dispersion film is a stainless steel sintered film with a pore diameter of 1 μm, a porosity of 50%, and a film thickness of 0.3 mm; the parameters for selecting the gas-in-oil dispersion film are: the oil The air-encapsulated disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com