Artificial perlite and puffed products and preparation method of artificial perlite

A technology for artificial pearls and products, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of devitrification, large differences in natural perlite grades, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

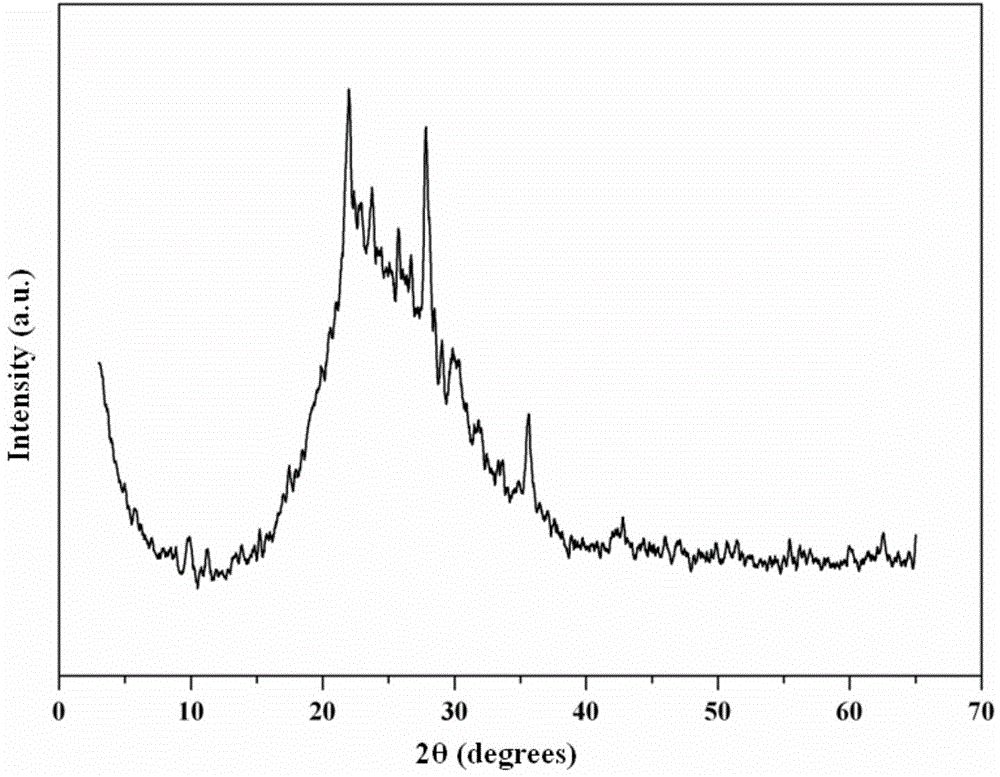

Image

Examples

Embodiment 1

[0106] In the present embodiment, the calcium-based bentonite used has a chemical composition and content as shown in Table 1-1; the sodium silicate used has a modulus of m=2.8 and a solid content of 37%, and its parameters are shown in Table 1-2 shown. The experimental materials selected in the experiment are all qualified industrial-grade raw materials, and no optimization processing has been carried out before the experiment.

[0107] Table 1-1 Chemical composition and content of calcium-based bentonite

[0108] chemical composition

SiO 2

Al 2 o 3

Fe 2 o 3

FeO

TiO

CaO

MgO

MnO

K 2 o

Na 2 o

P 2 o 5

Content (wt%)

65.04

16.08

1.12

0.20

0.27

5.01

2.13

0.29

1.00

0.22

0.05

[0109] Table 1-2 Parameters of sodium water glass

[0110]

[0111] Compared with natural perlite, in the chemical composition of calcium-based bentonite, Al 2 o 3 Higher con...

Embodiment 2

[0129]The reason why natural perlite is widely used is that it can expand into a lightweight material with a honeycomb structure at high temperature, but the expansion temperature of natural perlite is relatively high, which is 1050-1350 °C; and the expansion multiple mainly depends on the natural perlite ore. grade. Artificial perlite not only has the same puffing characteristics as natural perlite, but also has a low puffing temperature. The preparation process does not require mechanical crushing, basically does not generate dust pollution, and the puffed products have excellent chemical stability. In the present embodiment, test the expansion ratio of artificial perlite in the following way:

[0130] 1. Use a 10ml graduated cylinder to take an appropriate amount of the sample to be tested, about 1ml, and record it as V 1 (Try to vibrate and compact until the volume no longer changes);

[0131] 2. Quickly pour the sample into the burning porcelain evaporating dish (the ac...

Embodiment 3

[0145] In this embodiment, the influence of the water glass modulus on the various properties of the artificial perlite and its puffed products described in the present invention will be explored. Choose 1# and 2# two kinds of sodium silicate with different modulus, and the parameters of the silicate are shown in Table 3-1:

[0146] 3-1 Two kinds of water glass parameters used in the experiment

[0147]

[0148]

[0149] With above-mentioned two kinds of water glass as raw material respectively, the artificial perlite that is raw material with 1# water glass is defined as 1#, and the artificial perlite that is raw material with 2# water glass is defined as 2#, according to Al 2 o 3 The content is from 14% to 4%, and the formulas of 1# and 2# artificial perlite are respectively defined as 3-1~3-11 and 3-12~3-22, and the above formulas are prepared by molding trapping method or mechanical shearing method artificial perlite. The experimental results show that the appeara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com