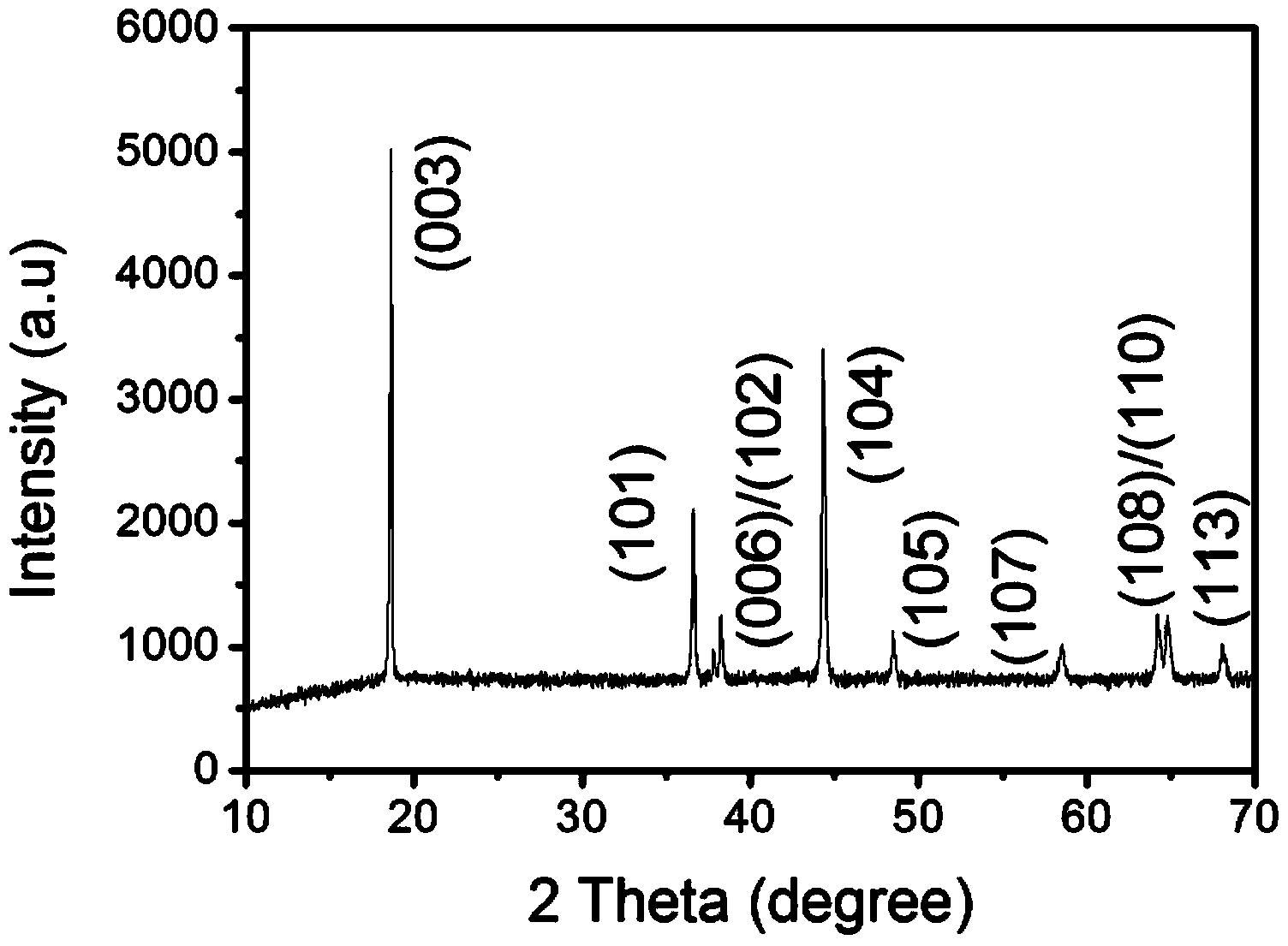

Preparation method for high-tapping-density modified nickel-cobalt lithium manganate positive material

A technology of nickel cobalt lithium manganate and positive electrode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of complicated preparation process, wide particle size distribution, difficult to uniform particle size, etc., and achieve excellent cycle performance and good dispersion effect. , the effect of easy temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] NiSO 4 , MnSO 4 、CoSO 4 According to the molar ratio Ni:Co:Mn=5:2:3, the mixed aqueous solution of nickel manganese cobalt salt is prepared, the total concentration is 1mol / L, and 1% magnesium acetate and 1% cerium nitrate are added to the solution, and another 2.0mol / L NaOH solution and 6.0mol / L ammonia water, the multi-component salt solution, NaOH solution, and ammonia water are respectively input into the reaction vessel filled with sodium citrate in advance with a metering pump for reaction. Under the protection of nitrogen, control the temperature of the reactor to 60°C, control the flow of alkali to make the pH value 11.0, and the stirring speed to 500r / min. The reactor feed liquid is naturally discharged, and the feed is continuously fed for 60 hours. Transfer the material in the kettle to the aging tank, add 2mol / L NaOH solution to adjust the pH to 12.0, stir for 4.0h for surface treatment, then filter for solid-liquid separation, wash the solid product obta...

Embodiment 2

[0043] NiCl 2 , CoCl 2 , MnCl 2 Prepare a nickel-manganese-cobalt mixed aqueous solution according to the molar ratio Ni:Co:Mn=4:2:4, the total concentration is 2.5mol / L, and add 1% aluminum nitrate and 2% potassium tantalate to the solution to prepare 10.0mol / L NaOH solution and ammonia solution with a concentration of 6.0mol / L, use a metering pump to respectively input the multi-component salt solution, sodium hydroxide solution, and ammonia solution into the reaction vessel filled with EDTA in advance for reaction. Under the condition of argon protection, the temperature of the reaction vessel is controlled at 50°C, the pH value is 10.8, the stirring speed is 800r / min, the material liquid in the reaction vessel is discharged naturally, the continuous feeding is stopped for 60 hours, and the material in the reaction vessel is transferred to mature tank, add 4mol / L NaOH solution to adjust the pH to 11.5, stir for 1.0h for solid-liquid separation until the pH value of the w...

Embodiment 3

[0046] Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 According to the molar ratio of Ni:Co:Mn=3:3:3, prepare nickel-manganese-cobalt mixed aqueous solution with a total concentration of 2.5mol / L, and add 0.5% zinc chloride and 0.5% indium chloride to the solution to prepare 10.0 The mol / L NaOH solution and the 6.0mol / L ammonia solution are used to input the multiple salt solution, the NaOH solution and the ammonia solution into the reaction vessel filled with sodium tartrate in advance with a metering pump for reaction. Under the condition of argon protection, the temperature of the reaction vessel is controlled at 50°C, the pH value is 10.8, the stirring speed is 200r / min, the material liquid in the reaction vessel is discharged naturally, the continuous feeding is stopped for 72 hours, and the material in the reaction vessel is transferred to mature tank, add 5mol / L NaOH solution to adjust the pH to 11.8, stir for 1.0h for solid-liquid separation until the pH value of the was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

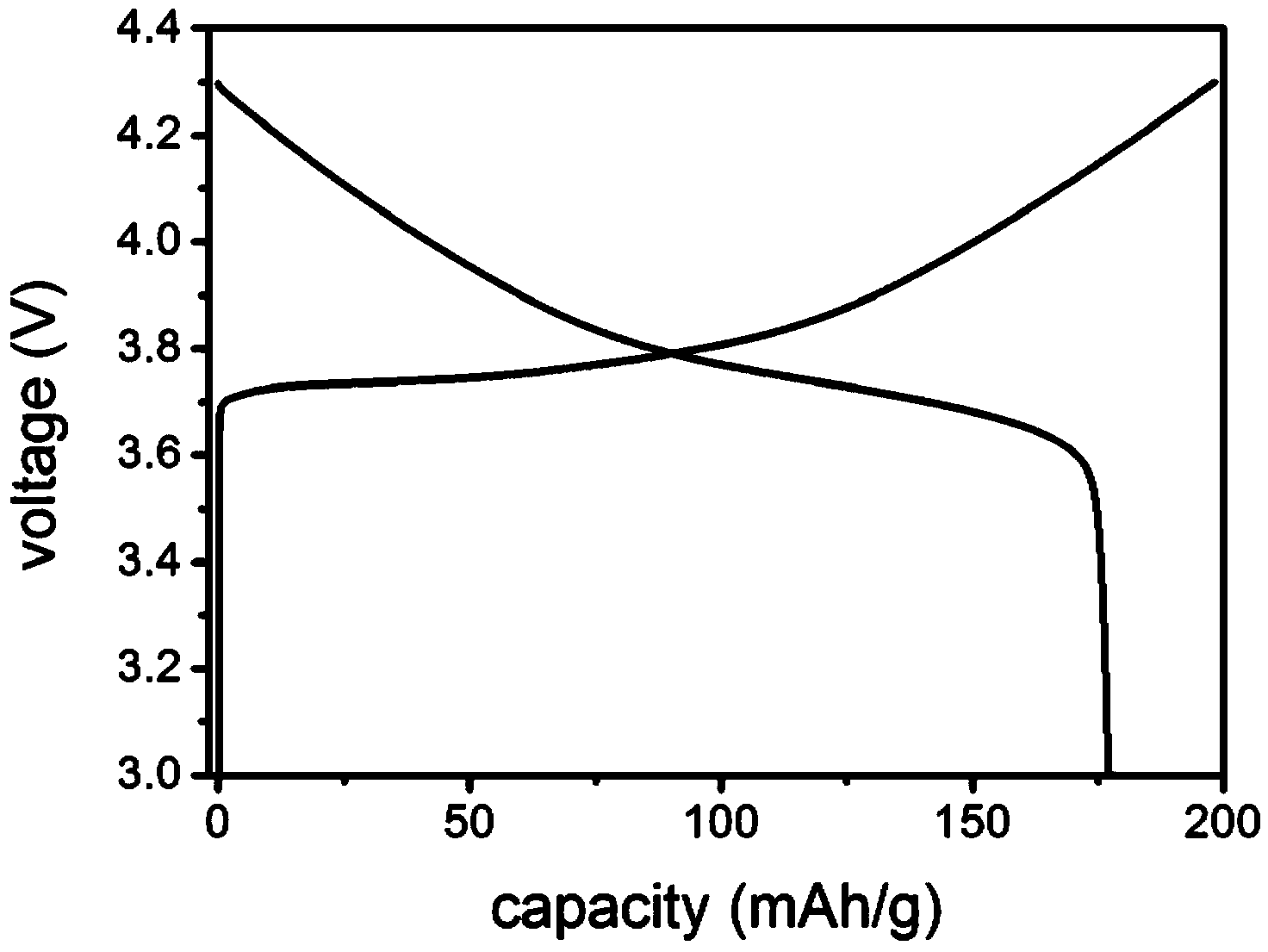

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com