Acid texturing additive for polysilicon film and use method thereof

An acid texturing, polycrystalline silicon wafer technology, applied in the field of polycrystalline silicon texturing of solar cells, achieves the effects of reducing the number of black wires, reducing surface defects, and having strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 is a comparison group example:

[0022] 1) Prepare acidic texturing solution: Add 3L of deionized water, 1.5L of hydrofluoric acid with a concentration of 49%, and 5.5L of nitric acid with a concentration of 68-71% into the texturing tank and stir to obtain 10L of acidic texturing liquid;

[0023] 2) Texturing: put the solar polysilicon wafer into the texturing tank for texturing, the temperature for texturing is 8°C, and the time for texturing is 80s.

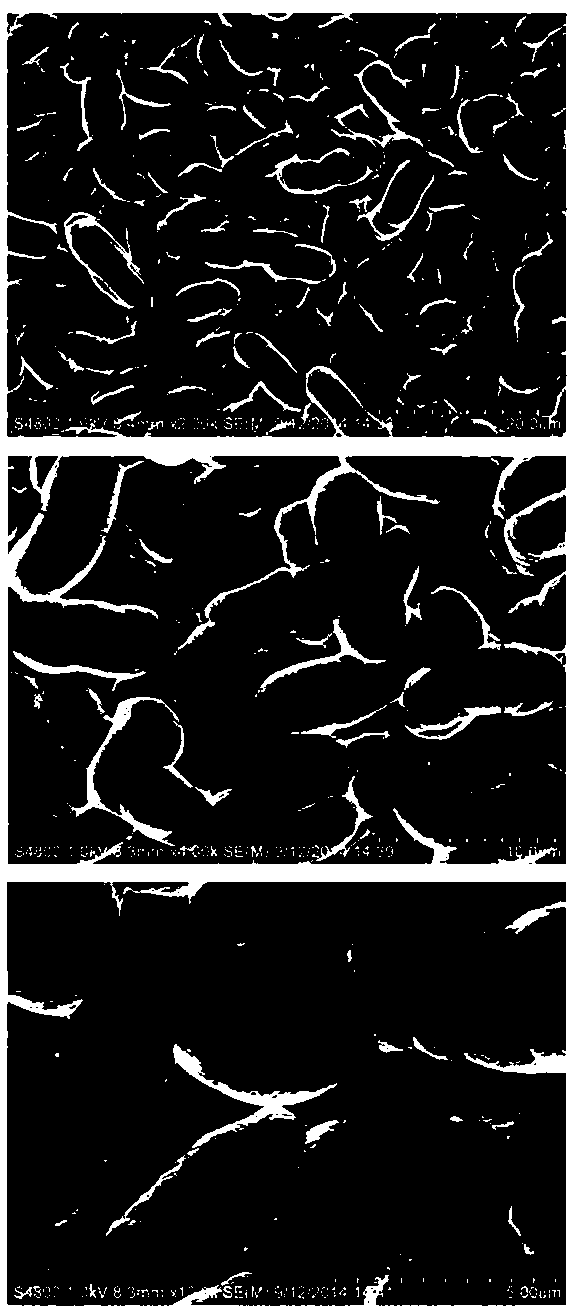

[0024] The reflectance after conventional texturing is 24.0%, which is determined by figure 1 It can be seen that suede with large size and uneven distribution was obtained.

Embodiment 2

[0026] 1) Configure polycrystalline texture additive: 0.01g perfluorinated nonionic surfactant, 0.05g pentaerythritol, 0.05g citric acid are added in 100ml deionized water to make polycrystalline texture additive;

[0027] 2) Prepare acidic texturing solution: add 3L of deionized water, 1.5L of hydrofluoric acid with a concentration of 49%, and 5.5L of nitric acid with a concentration of 68-71% into the texturing tank and stir to obtain 10L of acidic texturing liquid;

[0028] 3) Add 0.2L additive to the acidic texturing solution prepared in step 2);

[0029] 4) Texturing: put the solar polysilicon wafer into the texturing tank for texturing, the temperature for texturing is 8°C, and the time for texturing is 80s.

Embodiment 3

[0031] 1) Obtain the configuration polycrystalline texture additive: add 5g perfluorinated non-ionic surfactant, 5g n-butanol, 5g citric acid into 100ml deionized water to make polycrystalline texture additive;

[0032] 2) Prepare acidic texturing solution: add 3L of deionized water, 1.5L of hydrofluoric acid with a concentration of 49%, and 5.5L of nitric acid with a concentration of 68-71% into the texturing tank and stir to obtain 10L of acidic texturing liquid;

[0033] 3) Add 0.05L additive to the acidic texturing solution prepared in step 2);

[0034] 4) Texturing: put the solar polysilicon wafer into the texturing tank for texturing, the temperature for texturing is 8°C, and the time for texturing is 80s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com