Method for synthesizing beta-phase indium selenide flaky nanocrystalline by using hydrazine hydrate-assisted polyhydric alcohol solution

A nanocrystal, hydrazine hydrate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high cost and pollution, and achieve low cost, good repeatability, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The process parameters of Examples 1-6 are injection temperature / reflux temperature. From the results in Table 2, it can be concluded that in Example 1, that is, when the injection temperature / reflow temperature is 170 / 170°C, the phase of the synthesized product is Se without In 2 Se 3 phase generated. As the injection temperature / reflow temperature increases to 210 / 210°C, Se is reduced to generate α-In 2 Se3 , the synthetic product phase of Example 3 is a single α-In 2 Se 3 . The injection temperature / reflux temperature increased from 250 / 250°C to 270 / 270°C, and the synthetic products of Examples 5 and 6 were single sheet-like β-In 2 Se 3 . The stoichiometric ratios of Examples 2-6 are all close to the stoichiometric ratio of the reaction solution In:Se=1:1.5, and Example 6 is the best. The morphology of the synthesized product increases with temperature, and the α-In 2 Se 3 to β-In 2 Se 3 Phase transition, the morphology changes from granular to flake. Fr...

Embodiment 11

[0041] The process parameter of embodiment 11,12 is that the addition amount of hydrazine hydrate is different. Wherein the synthetic product of embodiment 11 is γ-In 2 Se 3 Mixed phase with Se, Example 12 is β-In 2 Se 3 , γ-In 2 Se 3 Mixed phase with Se. From the results of the stoichiometric ratio of the synthetic products in Examples 11, 12, and 6, with the increase of hydrazine hydrate, the stoichiometric ratio of the synthetic product is closer to the ideal stoichiometric ratio of In:Se=1:1.5. At the same time, in Example 6, Se is fully reduced to form a single phase β-In 2 Se 3 . From the above analysis, it can be seen that, for the parameters of the amount of hydrazine hydrate added, Example 6 is the optimum amount of hydrazine hydrate added, which is 0.1 ml.

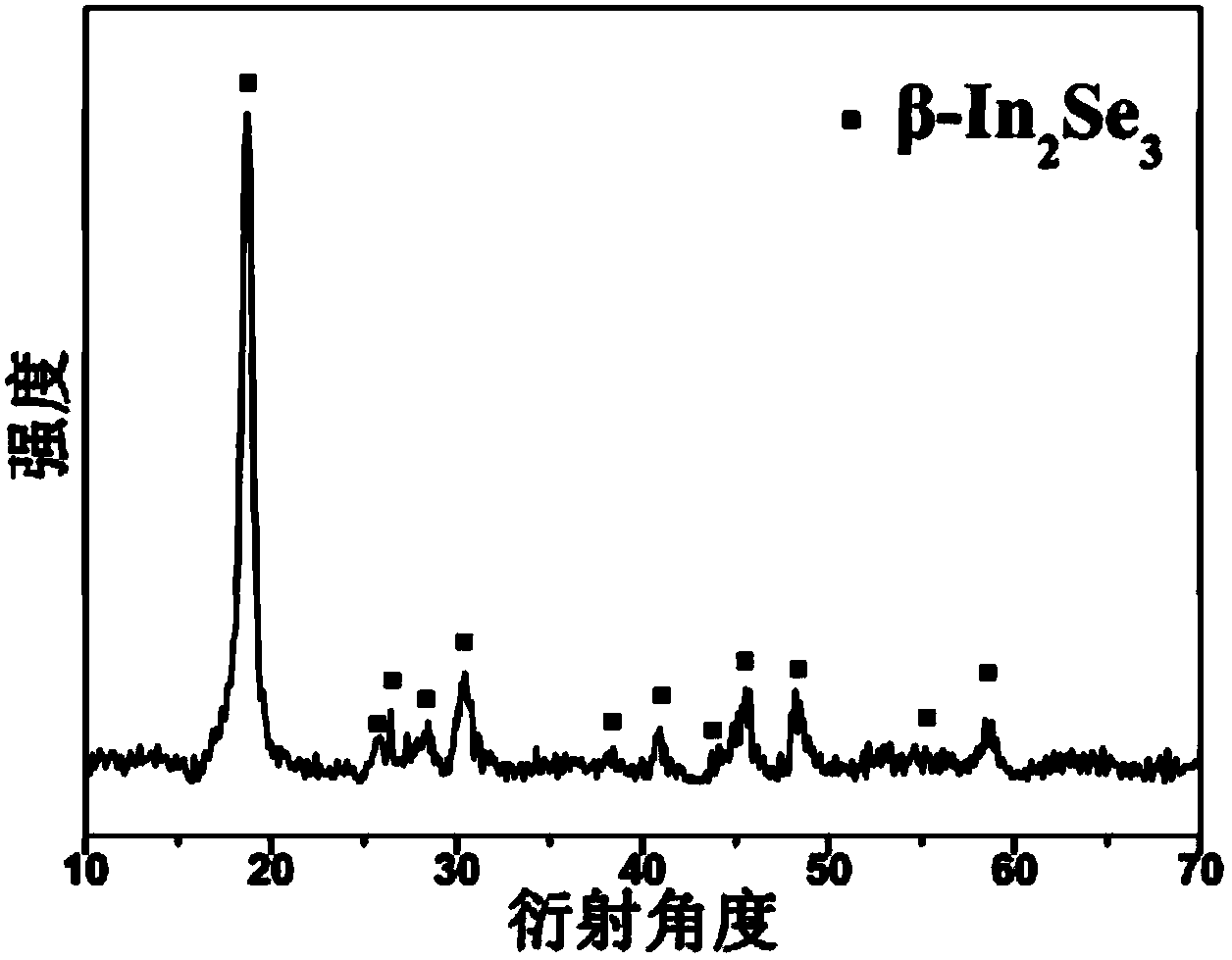

[0042] figure 1 It is the XRD spectrum of the synthetic product of Example 6, as can be seen from the figure that the product is a single sheet-like β-In 2 Se 3 .

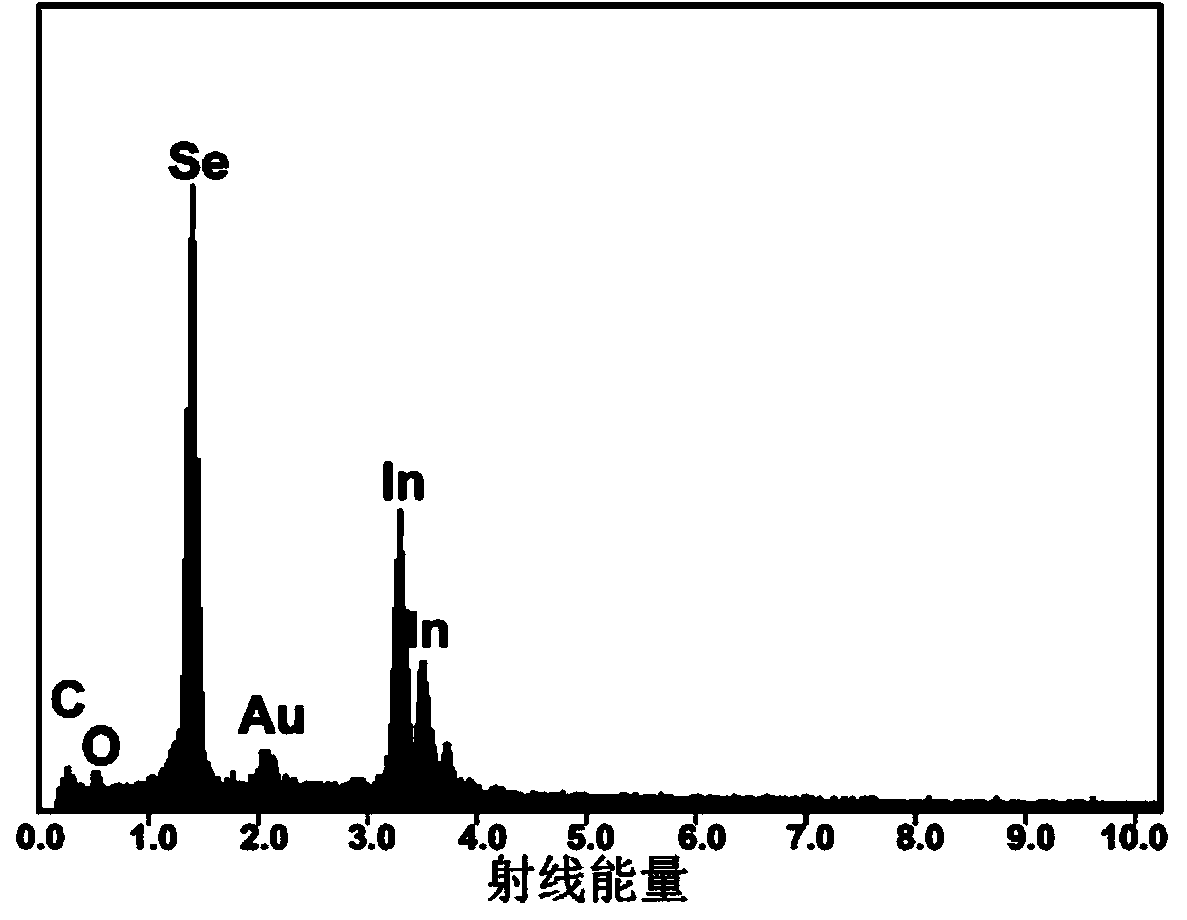

[0043] figure 2 It is the SEM pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com