Ingot mold inner-hole sweeping and polishing headstock

A steel ingot mould, sweeping and grinding technology, applied in the field of steel ingot mold processing, can solve the problems of high labor intensity, poor grinding effect, and backwardness, and achieve the effect of reducing labor intensity of employees and improving grinding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

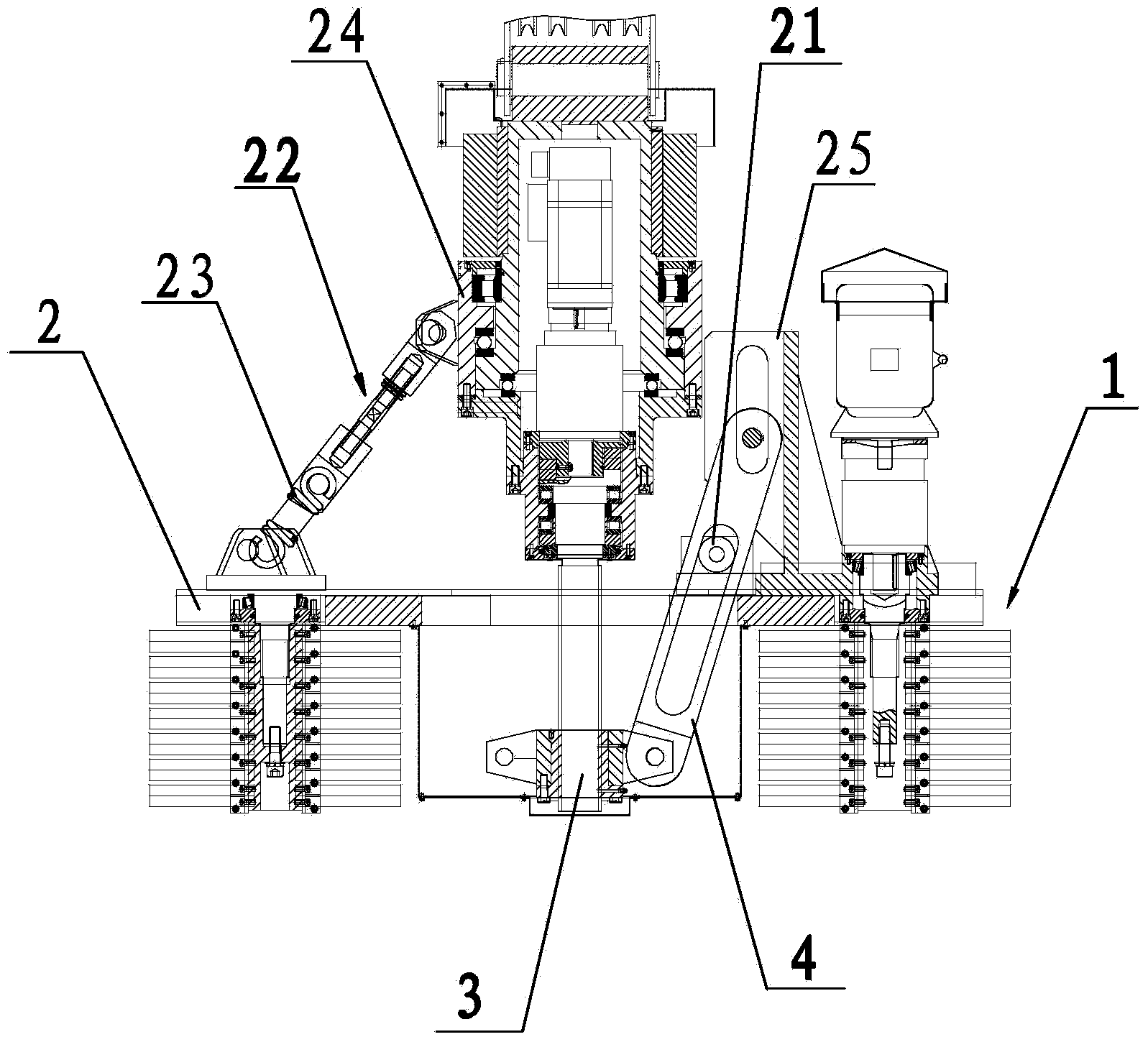

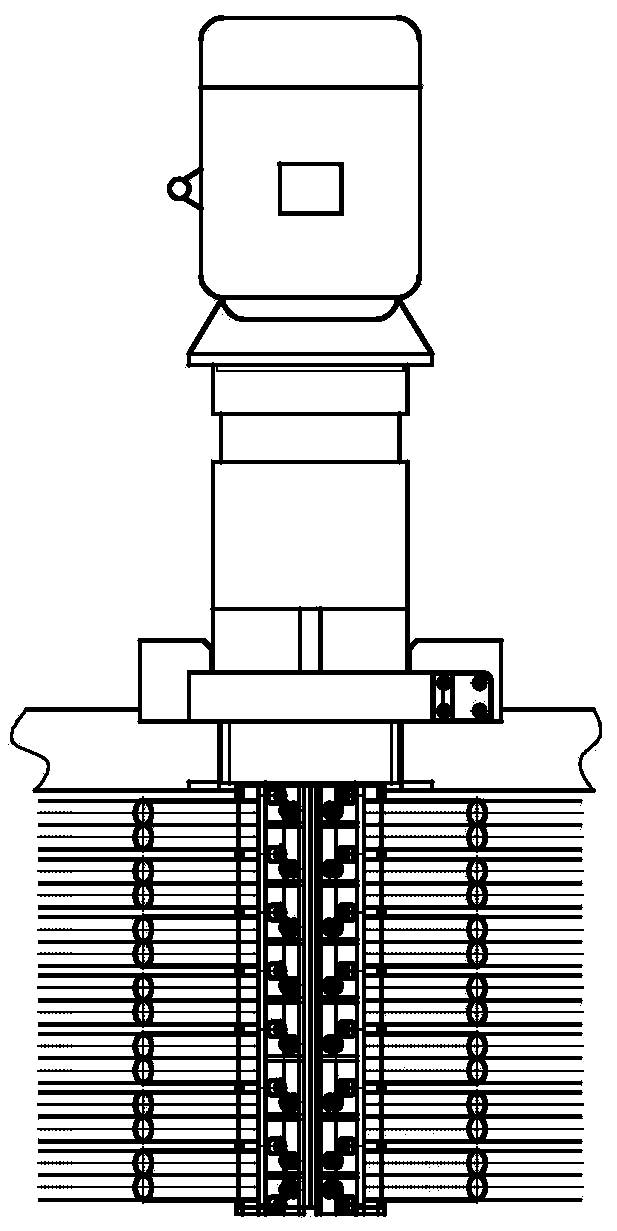

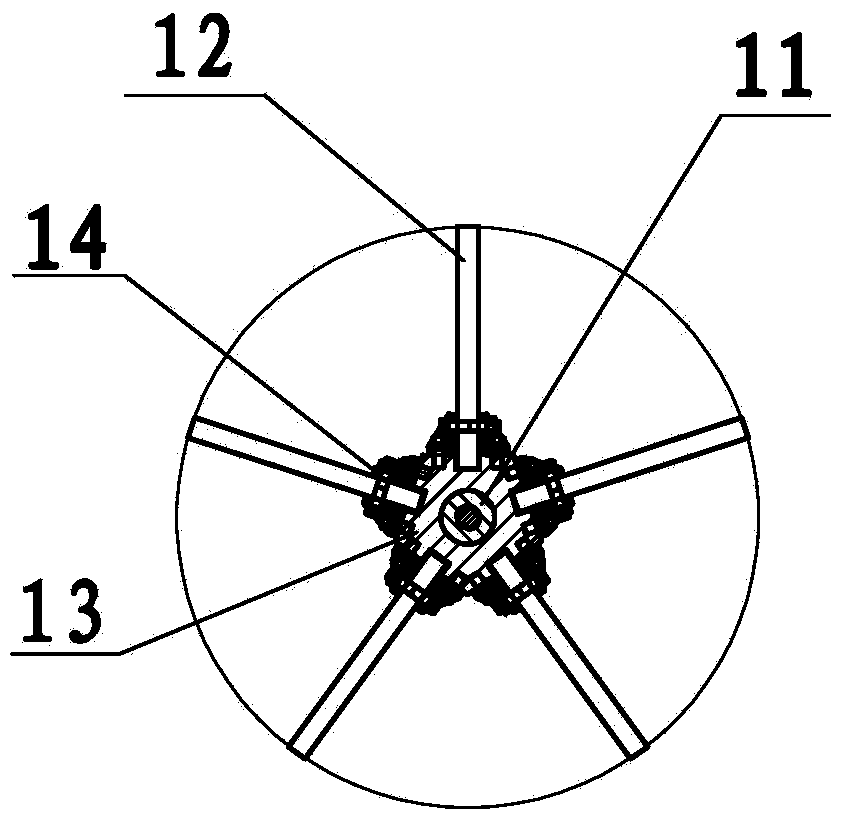

[0027] As shown in the figure (in order to show clearly, only one of the sweeping roller brush 1, connecting rod 22, and sliding seat 25 is made in the figure), a steel ingot mold inner hole sweeping head frame disclosed by the present invention includes sweeping Grinding roller brush 1, connection plate 2, said sweeping grinding roller brush 1 has six, evenly distributed in the slide seat 25 on the connection plate 2, and the slide seat 25 can slide in the chute provided in the radial direction of the connection plate 2 .

[0028] The sweeping roller brush 1 comprises a rotating shaft 11 driven by a motor, and a brush arranged on the rotating shaft 11. In this embodiment, the brush is composed of a brush cover 13 and a steel wire rope 12. The brush cover 13 is sleeved outside the rotating shaft 11. The cover 13 is a pentagonal prism, and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com