Vertical pneumatic damping grinding machine

A kind of grinding machine and vertical technology, which is applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problems of high labor intensity and serious health hazards of workers, so as to improve the quality and efficiency of grinding and ensure rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

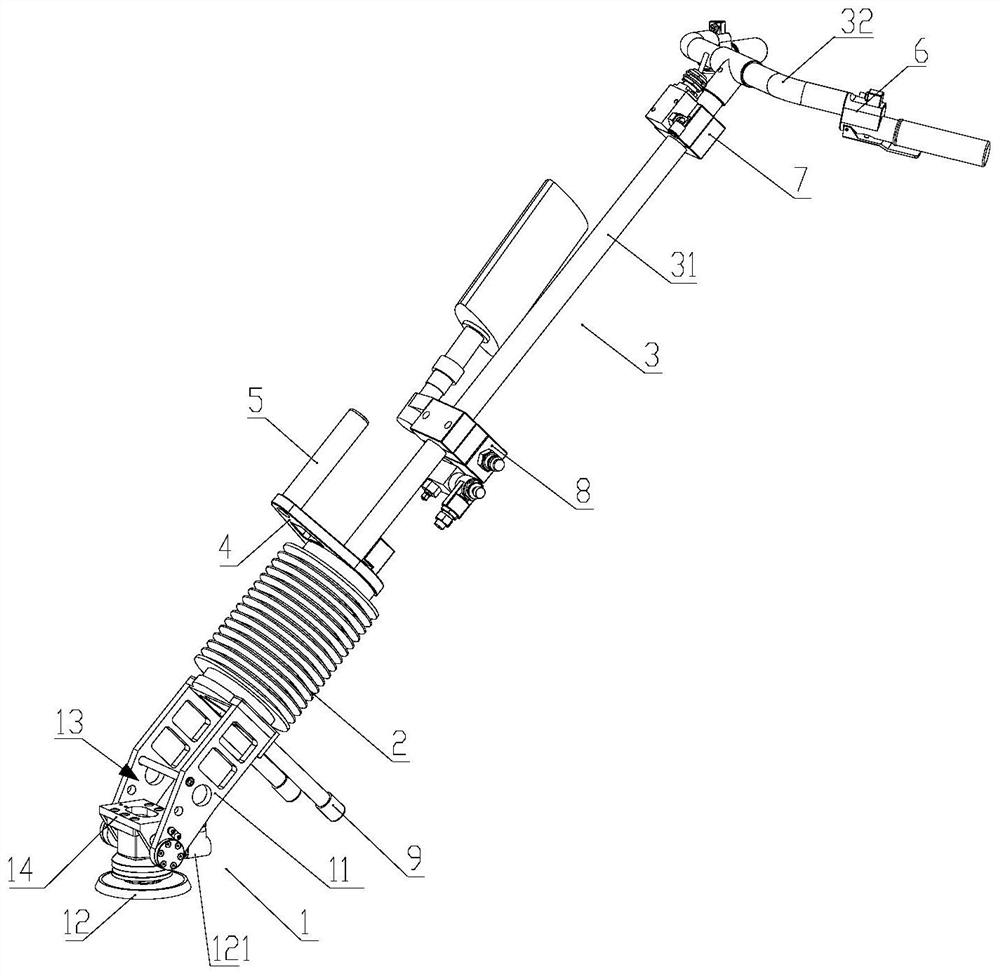

[0058] Such as figure 1 As shown, the vertical pneumatic shock-absorbing grinding machine of this embodiment includes: an end effector 1 , a shock-absorbing device 2 and a control handle 3 .

[0059] Such as figure 1 As shown, the end effector 1 includes at least one grinding bracket 11 and a pneumatic grinding head 12 installed on the grinding bracket 11; in this embodiment, the end effector 1 includes a grinding bracket 11; the pneumatic grinding The head 12 has a pneumatic joint 121 for connecting to an air source, and the air source provides power for the pneumatic grinding head 12 .

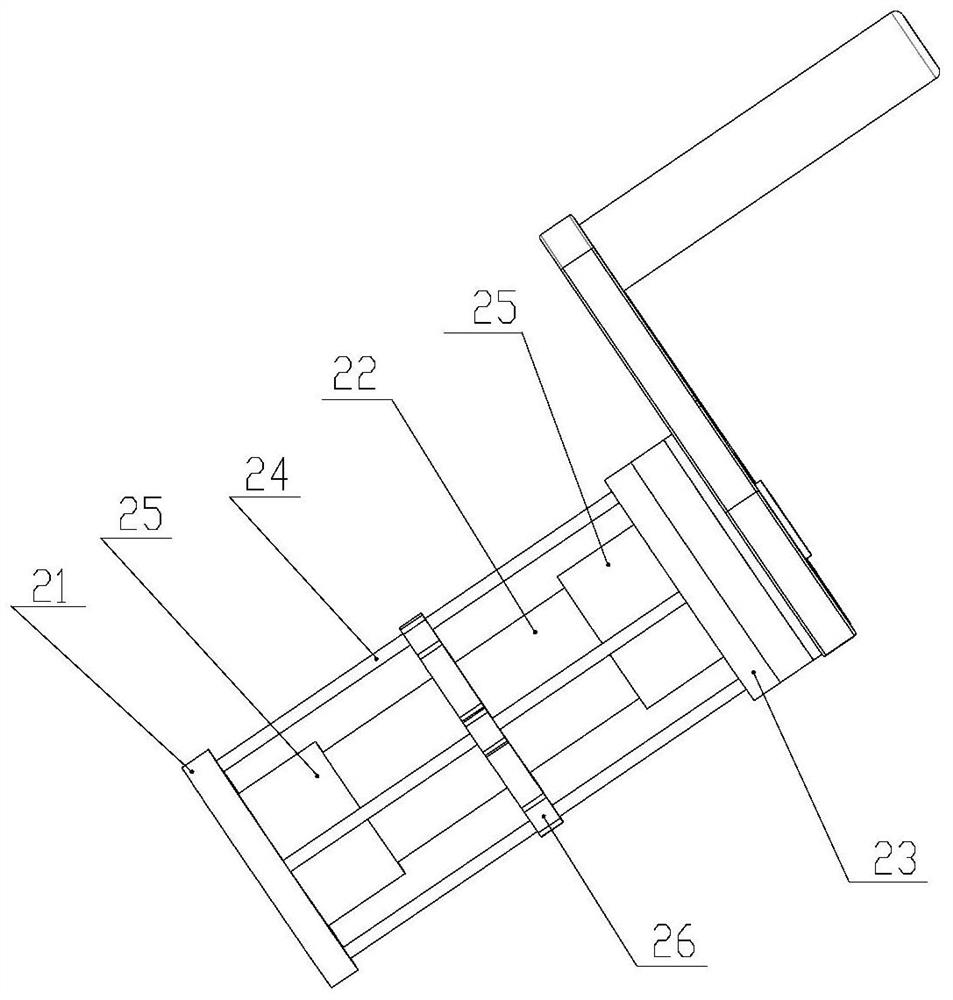

[0060] Such as figure 1 and figure 2 As shown, the shock absorbing device 2 includes a first connecting flange 21, a buffer spring 22, a second connecting flange 23 connected in sequence, and a plurality of pre-tensioned steel wires 24 evenly distributed around the buffer spring 22; wherein the first connection The flange 21 is connected to the grinding bracket 11, and the two ends of e...

Embodiment 2

[0082] The technical scheme of embodiment 2 is basically the same as embodiment 1, and its main difference is: as Figure 6 As shown, the vertical rod 31 forms an obtuse angle with the central axis of the buffer spring 22, and the distance between the horizontal rod 32 and the pneumatic grinding head 12 is the same as the distance between the operator's hand and the desktop when standing. Fitting: the end effector 1 is rotatably connected to the first connecting flange 21 . Specifically, the vertical rod 31 is a short rod, and it forms an obtuse angle with the central axis of the buffer spring 22, so that the operator can directly polish the fixed parts on the desktop or the workbench in a standing posture, which is more ergonomic, and The end effector 1 and the shock absorbing device 2 can rotate relatively, and the end effector 1 can adapt to the deflection angle of the grinding surface during the grinding process.

[0083]In order to facilitate the movement of the vertical...

Embodiment 3

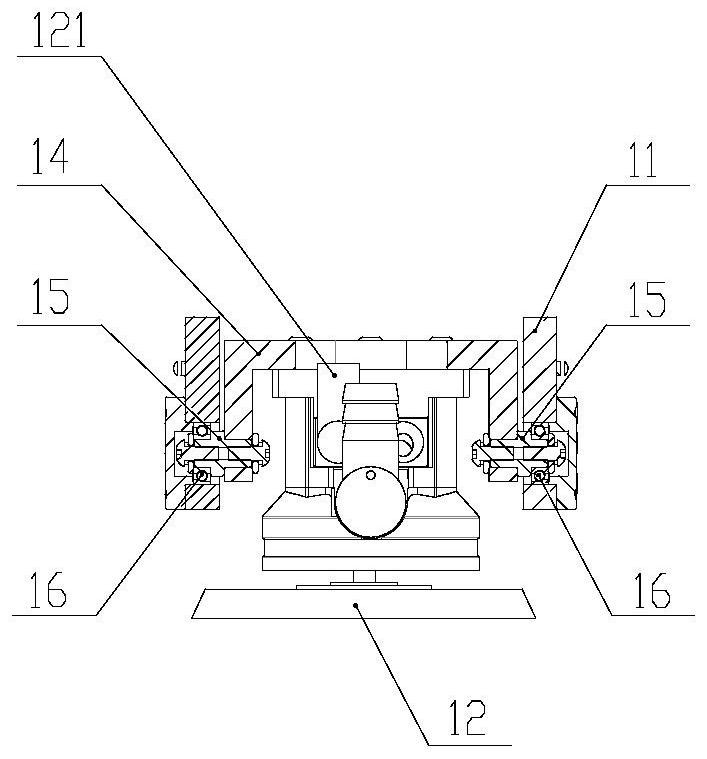

[0085] Such as Figure 8 As shown, the end effector 1 of the vertical pneumatic shock-absorbing grinding machine of this embodiment has two grinding brackets 11, and each grinding bracket 11 is provided with a pneumatic grinding head 12, a grinding fixed plate 14, a rotating shaft 15 and a bearing 16 . The pneumatic grinding head 12 on each grinding support 11 can be rotated independently to adapt to different radians at different positions on the grinding surface.

[0086] It should be noted that Embodiment 3 can be obtained by making improvements on the basis of Embodiment 1 or Embodiment 2. Without affecting understanding, this embodiment only shows a vertical pneumatic shock-absorbing grinder with a long vertical rod .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com