Multifunctional self-adaption ball valve grinding miller

A grinding machine and self-adaptive technology, which is applied in the direction of grinding machine tools, grinding devices, grinding/polishing equipment, etc., can solve the problems of contact error between the ball and the valve seat sealing surface, difficult quality assurance, and inability to process ball valves, etc., to achieve improved sealing High performance, high production efficiency, and the effect of ensuring the quality of the contact surface and contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

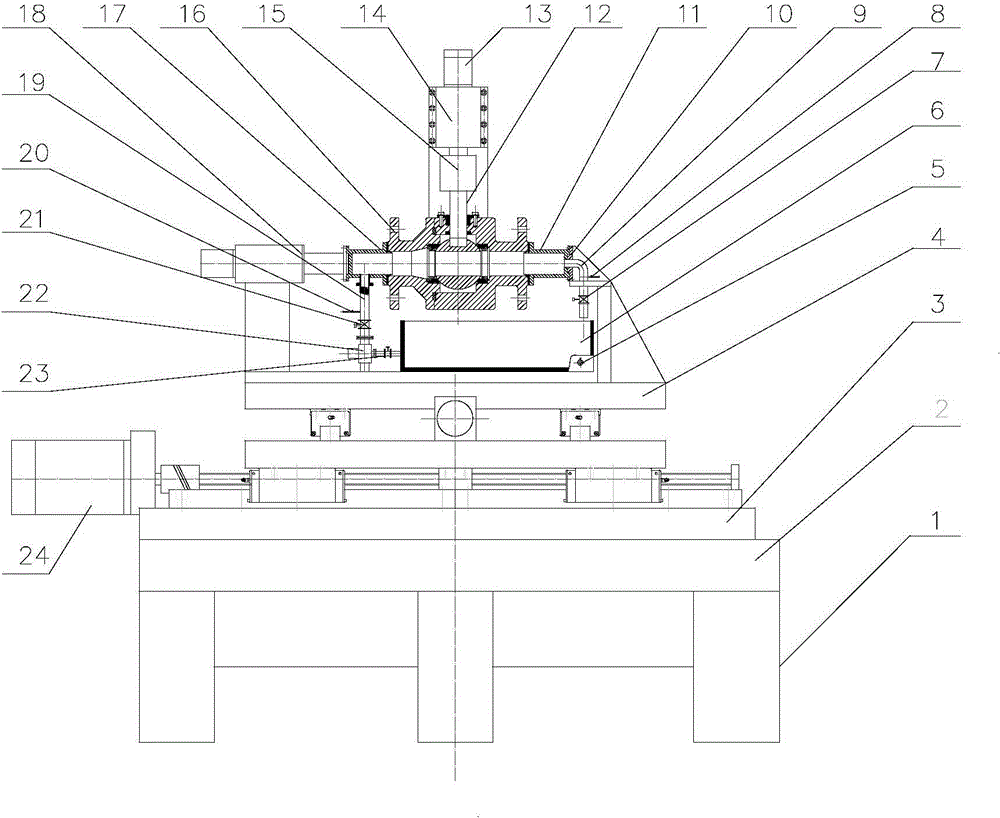

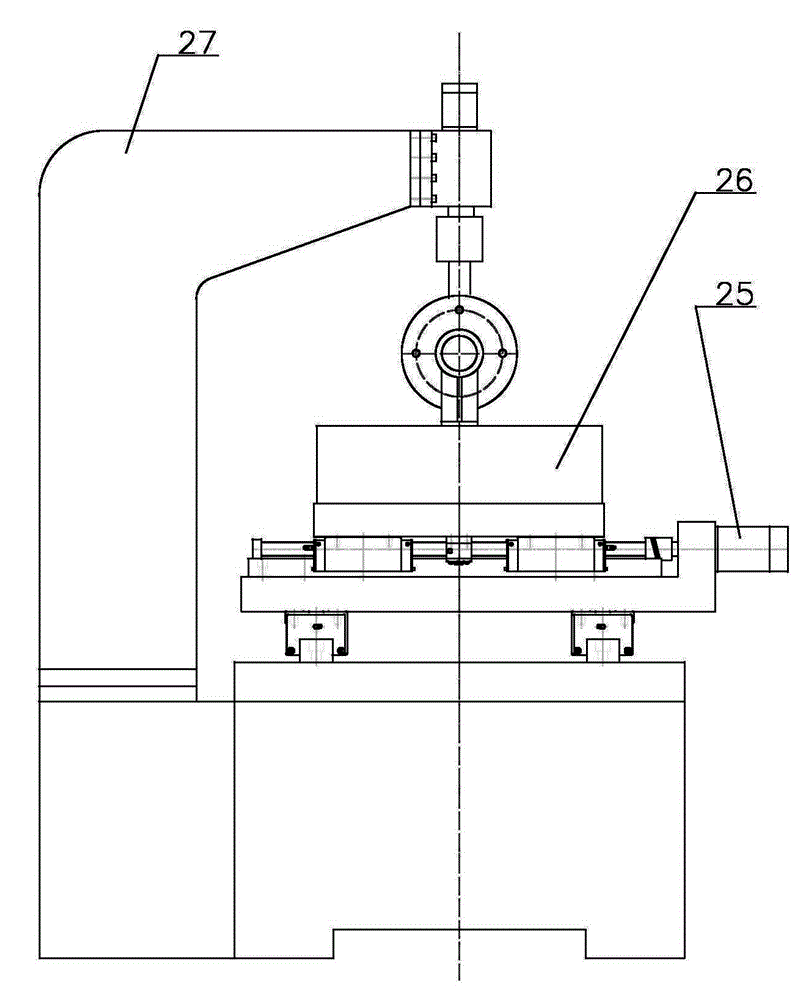

[0028] A multifunctional self-adaptive ball valve grinding machine, its structure is as follows Figure 1-2 As shown, the grinding machine includes a grinding structure, a liquid inlet and outlet structure, and a control structure.

[0029] The grinding structure is composed of a grinding head motor 13, a cone head valve stem 12, a grinding head 14, a valve stem chuck 15, and a workbench 4. The ball valve 16 to be processed is set on the workbench 4. The grinding head motor 13, the grinding head 14. The valve stem chuck 15 and the conical valve stem 12 are connected sequentially from top to bottom, and the ball valve 16 of the ball valve to be processed is ground. The grinding head motor 13 is connected to the grinding head column 27 on the workbench 4, and drives the valve core of the ball valve 16 to rotate at a high speed through the valve stem chuck 15 to achieve matching grinding with the valve seat, improve the grinding quality and efficiency, and ensure the sealing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com