Saw blade grinding frame of stone combined saw

A combined saw and saw blade technology, which is applied to the tool trimming of sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of uneven grinding, heavy grinding workload, time-consuming and labor-intensive, etc., to reduce labor and improve The effect of polishing quality and efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

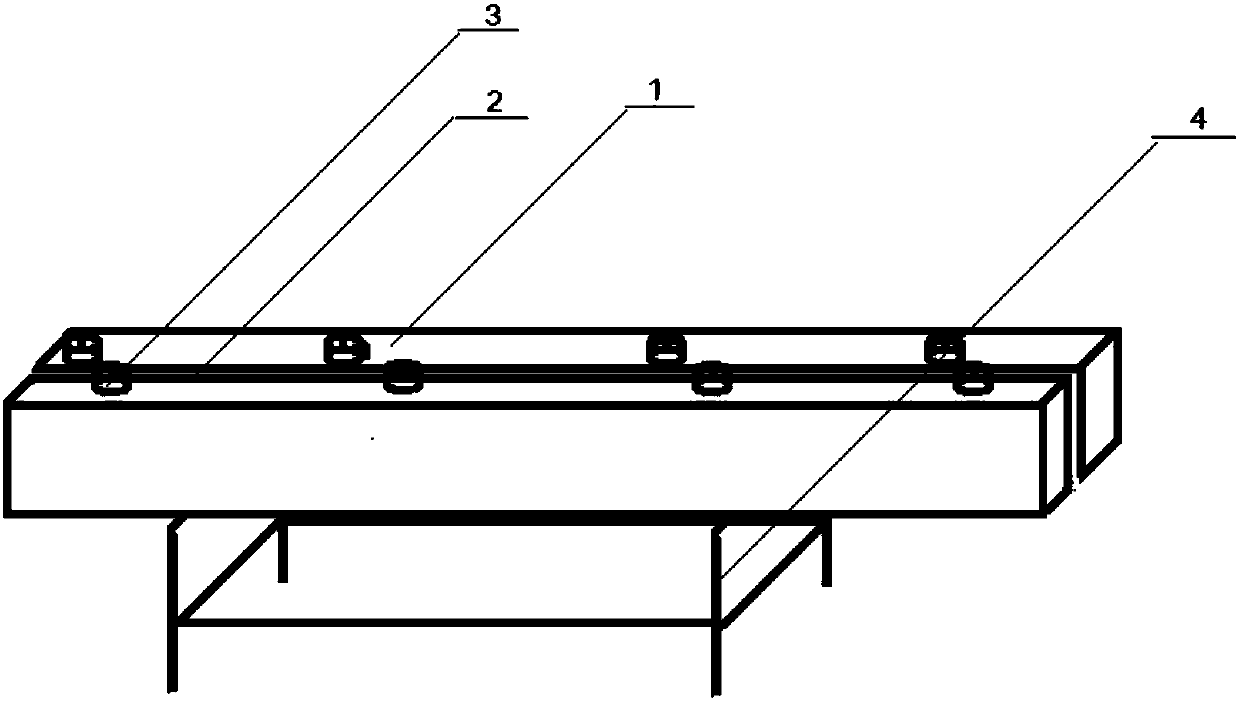

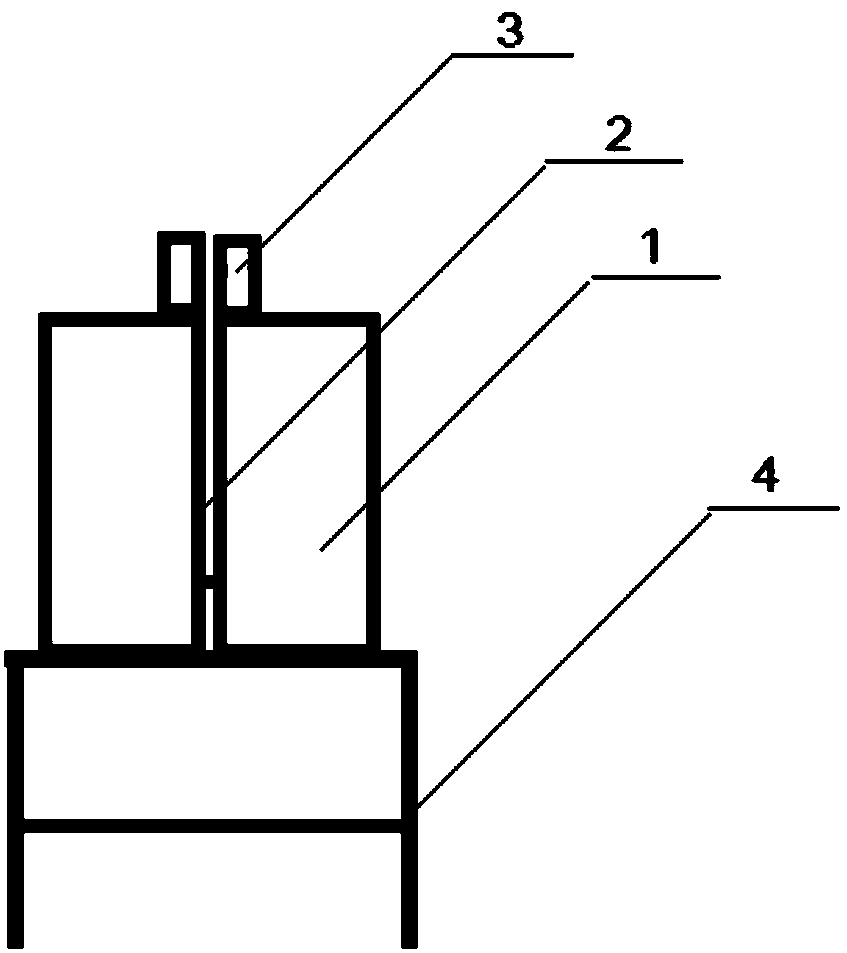

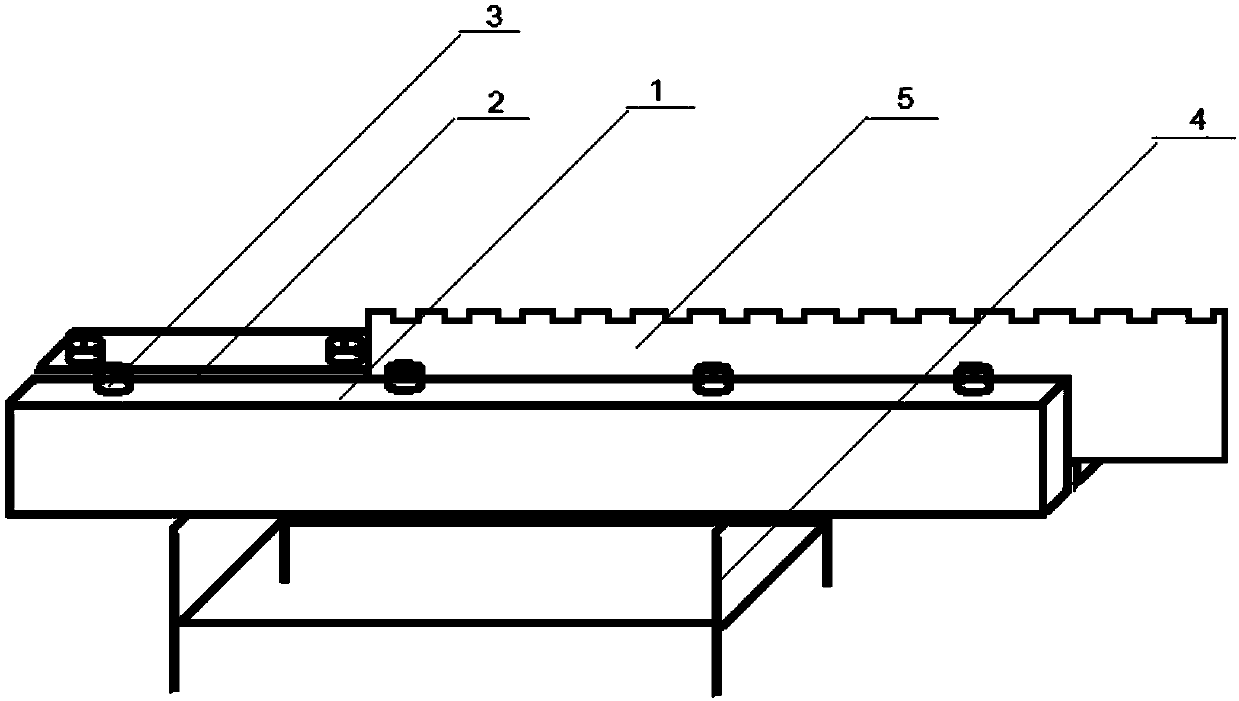

[0016] Embodiment 1: A saw blade grinding frame for a stone combined saw. The saw blade grinding frame for a stone combined saw is composed of a bracket 1, a saw blade groove 2, a guide wheel 3 and a support frame 4. The bracket 1 is in the shape of a rectangular strip , the upper middle part of the bracket 1 is provided with a saw blade slot 2 for placing the saw blade 5, the top saw blade slot 2 of the bracket 1 is provided with a guide wheel 3 to facilitate the sliding of the saw blade 5, a support frame 4 is provided under the bracket 1, and the stone The saw blade grinding frame of the combination saw is made of metal material, and the width of the saw blade groove 2 is 3 mm larger than the thickness of the saw blade 5 .

Embodiment 2

[0017] Embodiment 2: A saw blade grinding frame for a stone combined saw. The saw blade grinding frame for a stone combined saw is composed of a bracket 1, a saw blade groove 2, a guide wheel 3 and a support frame 4. The bracket 1 is in the shape of a rectangular strip , the upper middle part of the bracket 1 is provided with a saw blade slot 2 for placing the saw blade 5, the top saw blade slot 2 of the bracket 1 is provided with a guide wheel 3 to facilitate the sliding of the saw blade 5, a support frame 4 is provided under the bracket 1, and the stone The saw blade grinding frame of the combination saw is made of metal material, and the width of the saw blade groove 2 is 4mm larger than the thickness of the saw blade 5 . The depth of the saw blade groove 2 is 2 / 3 of the width of the saw blade 5 .

Embodiment 3

[0018] Embodiment 3: A saw blade grinding frame for a stone combined saw. The saw blade grinding frame for a stone combined saw is composed of a bracket 1, a saw blade groove 2, a guide wheel 3 and a support frame 4, and the bracket 1 is in the shape of a rectangular strip , the upper middle part of the bracket 1 is provided with a saw blade slot 2 for placing the saw blade 5, the top saw blade slot 2 of the bracket 1 is provided with a guide wheel 3 to facilitate the sliding of the saw blade 5, a support frame 4 is provided under the bracket 1, and the stone The saw blade grinding frame of the combination saw is made of metal material, and the width of the saw blade groove 2 is 5 mm larger than the thickness of the saw blade 5 . The depth of the saw blade groove 2 is 2 / 3 of the width of the saw blade 5 . The outer circular edge of the guide wheel 3 is on the same vertical line as the inner edge of the saw blade groove 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com