Composite active bone cement containing sustained release drug-loading nanoparticles and preparation method of bone cement

A drug-loaded nano and bone cement technology, applied in medical science, surgical adhesives, prostheses, etc., can solve the problems of poor bone conduction effect, poor water solubility, small pore size, etc., and achieve the effect of reducing the burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a revitalized bone cement containing sustained-release drug-loaded nanoparticles, comprising the steps of:

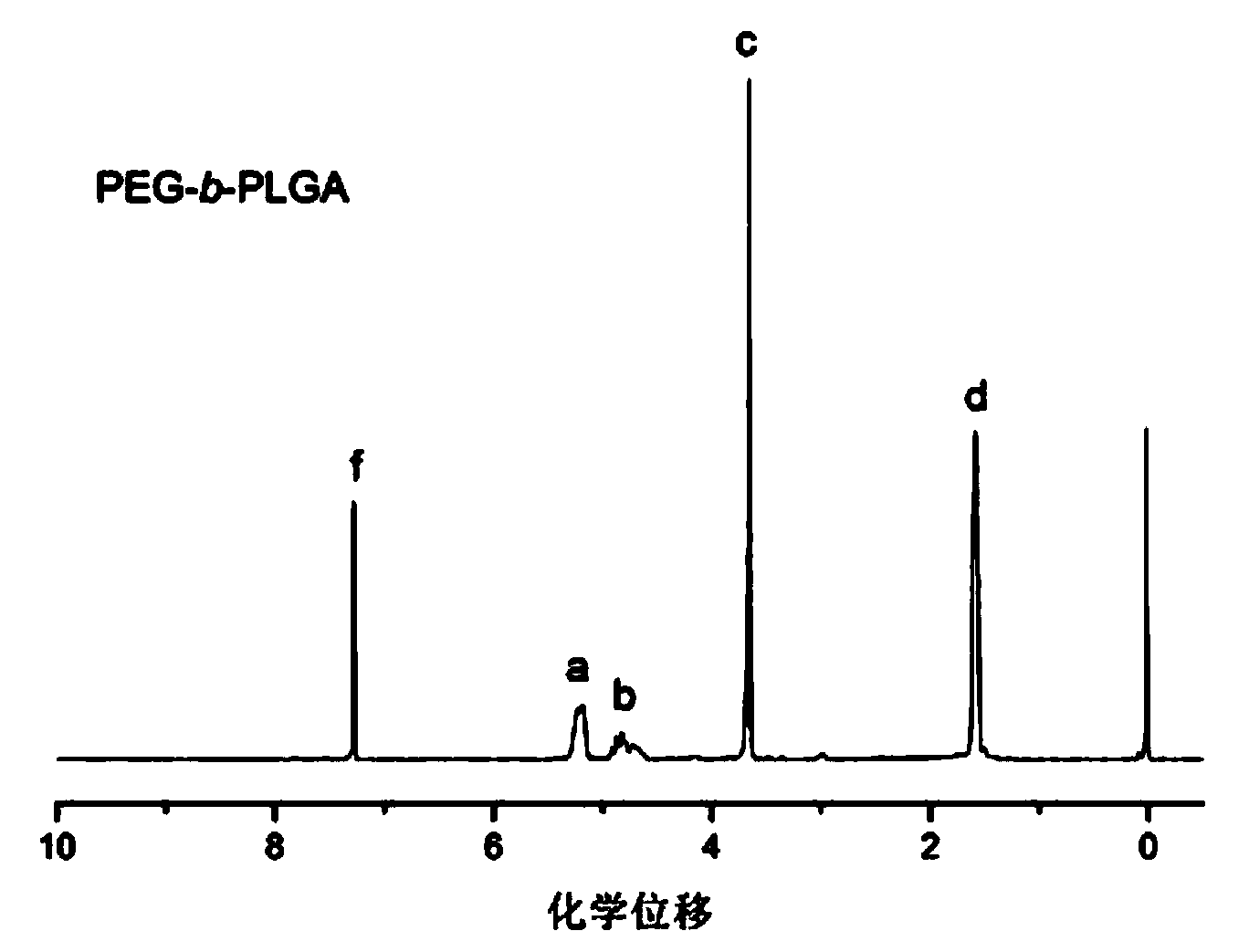

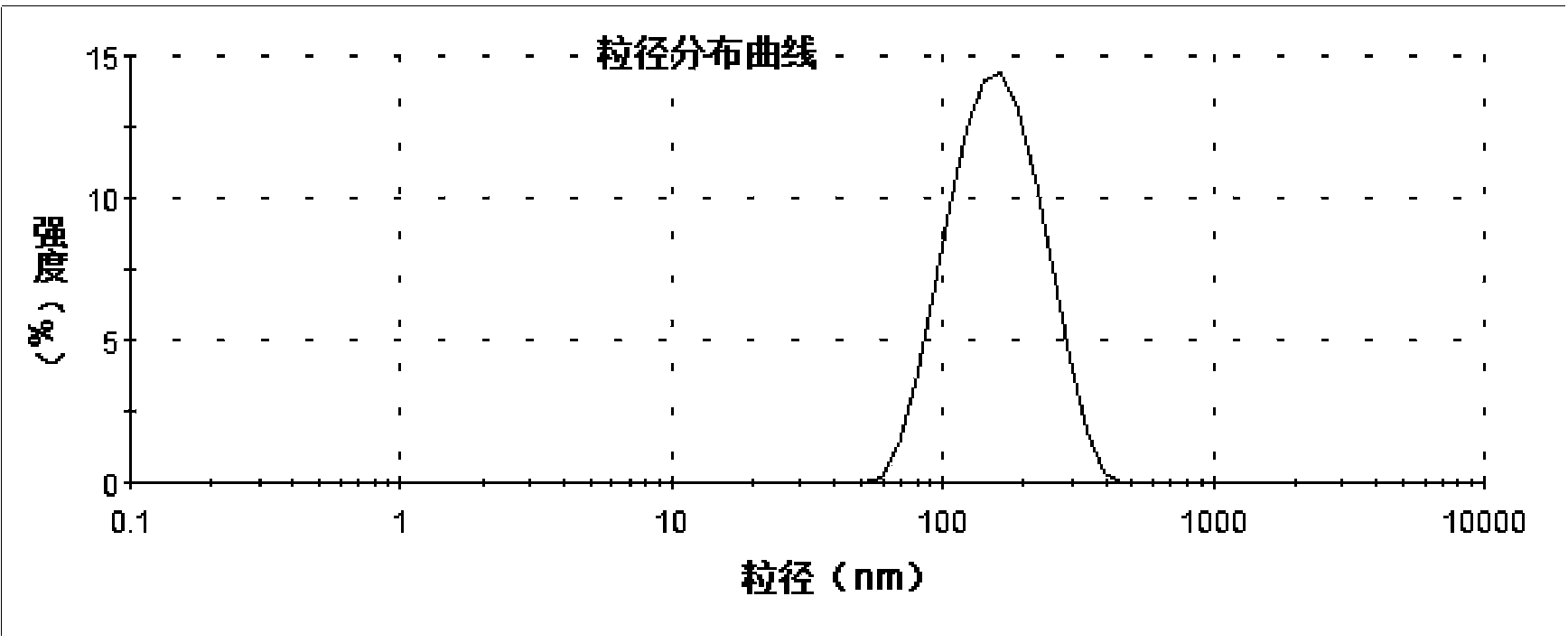

[0053] (1) Preparation of nanoparticles loaded with docetaxel:

[0054] Weigh 30% lactide monomer, 40% glycolide monomer and 29.9% polyethylene glycol (M w =5000) mix, put into the polymerization tube, then add the tributyl tin chloride that mass percent is 0.1% to obtain the mixed reaction raw material; Carry out vacuumizing and degassing and then fill with nitrogen, repeat three times, make the formation of nitrogen protection in the polymerization tube environment; the polymerization tube is sealed, and the ring-opening polymerization reaction is carried out under heating in an oil bath at 150°C, and the polymerization product is obtained after 6 hours of reaction; the obtained polymerization product is dissolved in the first organic solvent dichloromethane after cooling, and the polymerization The product includes the polymer generated...

Embodiment 2

[0076] A method for preparing a revitalized bone cement containing sustained-release drug-loaded nanoparticles, comprising the steps of:

[0077] (1) Preparation of nanoparticles loaded with doxorubicin:

[0078] Weigh 35% of lactide monomer, 29% of glycolide monomer and 35% of polyethylene glycol (Mw=5000) by mass percentage, mix them, put them into a polymerization tube, and add mass percentage Tributyltin chloride with a content of 1% is used to obtain mixed reaction raw materials; after vacuuming and degassing, nitrogen is filled, and repeated three times, so that nitrogen is formed in the polymerization tube to protect the environment; the polymerization tube is sealed and heated in an oil bath at 150°C. Ring-opening polymerization, reacting for 8 hours to obtain a polymer product; the resulting polymer product is cooled and dissolved in the first organic solvent chloroform, the polymer product includes polymers generated by the polymerization reaction, unreacted lactide ...

Embodiment 3

[0083] A method for preparing a revitalized bone cement containing sustained-release drug-loaded nanoparticles, comprising the steps of:

[0084] (1) Preparation of nanoparticles loaded with 5-fluorouracil:

[0085] Weigh 50% of lactide monomer, 40% of glycolide monomer and 9% of polyethylene glycol (Mw=2000) by mass percentage, mix them, put them into a polymerization tube, and add mass percentage The content of stannous isooctanoate with a content of 1% is obtained as a mixed reaction raw material; after vacuuming and degassing, nitrogen is filled, and repeated three times, so that nitrogen is formed in the polymerization tube to protect the environment; the polymerization tube is sealed, and the ring is opened under heating in an oil bath at 170°C Polymerization reaction, after 12 hours of reaction, a polymer product is obtained; the resulting polymer product is cooled and dissolved in tetrahydrofuran, the first organic solvent, and the polymer product includes the polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com