Method for synthesizing water-soluble conductive polymer by using nano black selenium peroxide mimic enzyme as catalyst

The technology of black selenium peroxide and conductive polymer is applied in the field of nano-black selenium peroxide simulating enzyme catalyzed synthesis of water-soluble conductive polymer, which can solve the problems of difficult purification, large environmental pollution, easy inactivation of natural enzymes, etc. Achieve the effect of green synthesis process, overcoming insoluble and infusible, and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of nanometer black selenium peroxide mimetic enzyme:

[0037] step:

[0038] Accurately weigh 0.222g selenium dioxide (SeO 2 ), dissolved in 5 mL of deionized water at room temperature, added 0.8 mL of concentrated sulfuric acid with a mass concentration of 98%, stirred for 5 minutes, added 30 mL of glycerol, continued to stir for 30 minutes, transferred the mixture to an autoclave, and reacted at 180 ° C After 6 hours, the product was centrifuged, and the centrifuged precipitate was washed three times with deionized water and ethanol respectively, and then vacuum-dried at 60° C. to obtain nano black selenium powder.

[0039] result:

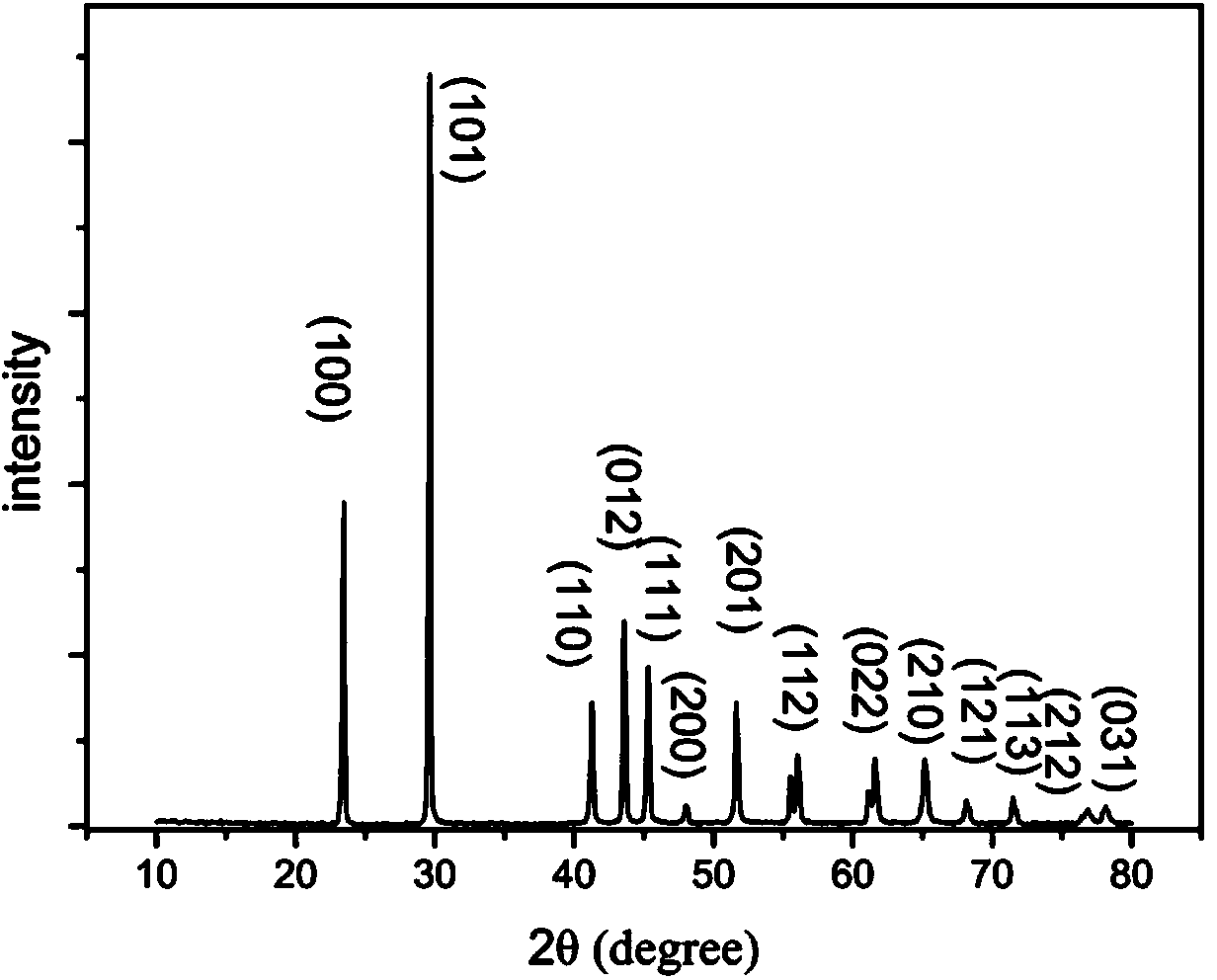

[0040] attached by figure 1 It can be seen that the prepared product is simple selenium with high purity.

[0041] attached by figure 2 It can be seen that the prepared black selenium is a spherical particle with a size between 500 nm and 10 μm.

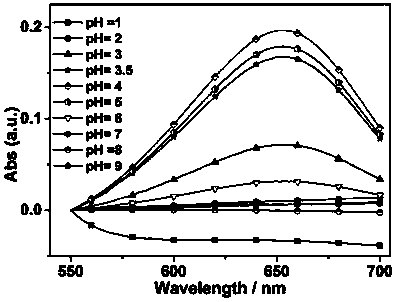

[0042] 2. Test of the simulated activity of nano black selenium peroxi...

Embodiment 2

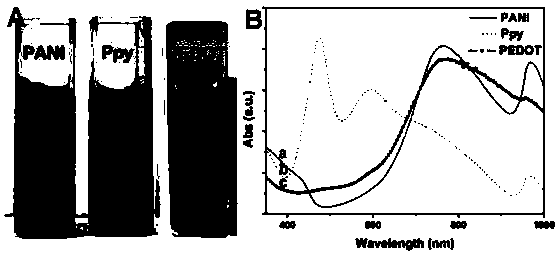

[0069] Synthesis of water-soluble conductive polyaniline PANI catalyzed by nano-black selenium peroxide mimetic enzyme:

[0070] step:

[0071] ① Accurately weigh 1 mmol (0.093 g) of aniline monomer and 1 mmol (0.206 g) of sodium polystyrene sulfonate, add them to 20 ml of citric acid-disodium hydrogen phosphate buffer solution with pH=2.2, and stir for 2 hours under ice bath .

[0072] ② Add 5 mg of nano black selenium peroxide mimetic enzyme, and react in a water bath at 40°C, so that aniline monomers can be polymerized under the catalysis of nano black selenium.

[0073] ③ The polymerization reaction was completed after 12 hours, and the reaction system was centrifuged at a speed of 3000 rpm for 10 minutes to remove the nano black selenium catalyst.

[0074] ④ Transfer the upper centrifugate into a dialysis bag with a molecular weight cut-off of 3500KDa, and dialyze in a hydrochloric acid solution with pH=5 for 24 hours to remove unreacted monomers and oligomers with smal...

Embodiment 3

[0076] Synthesis of water-soluble conductive polyaniline PANI catalyzed by nano-black selenium peroxide mimetic enzyme:

[0077] step:

[0078] ① Accurately weigh 2 mmol (0.186 g) of aniline monomer and 2 mmol (0.512 g) of sodium polystyrene sulfonate, add them to 20 ml of citric acid-disodium hydrogen phosphate buffer solution with pH=3.2, and stir for 3 hours under ice bath .

[0079] ② Add 10 mg of nano black selenium peroxide mimetic enzyme, and react in a water bath at 60°C, so that aniline monomers can be polymerized under the catalysis of nano black selenium.

[0080] ③After the polymerization reaction was completed for 24 hours, the reaction system was centrifuged at a speed of 3000 rpm for 10 minutes to remove the nano black selenium catalyst.

[0081] ④ Transfer the upper centrifugate into a dialysis bag with a molecular weight cut-off of 3500KDa, and dialyze in a hydrochloric acid solution with pH=5 for 24 hours to remove unreacted monomers and oligomers with smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com