Laser screen making machine

A network machine and laser technology, applied in the field of machinery, can solve the problems of inability to achieve accurate positioning of laser exposure, affect laser operation, and low operating accuracy, so as to improve dynamic performance and moving speed, improve stability and positioning accuracy, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

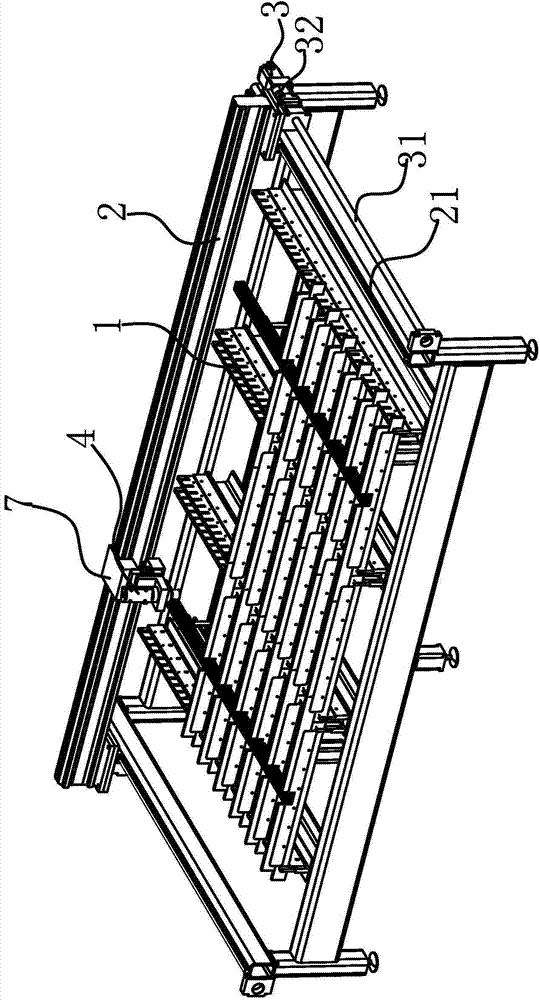

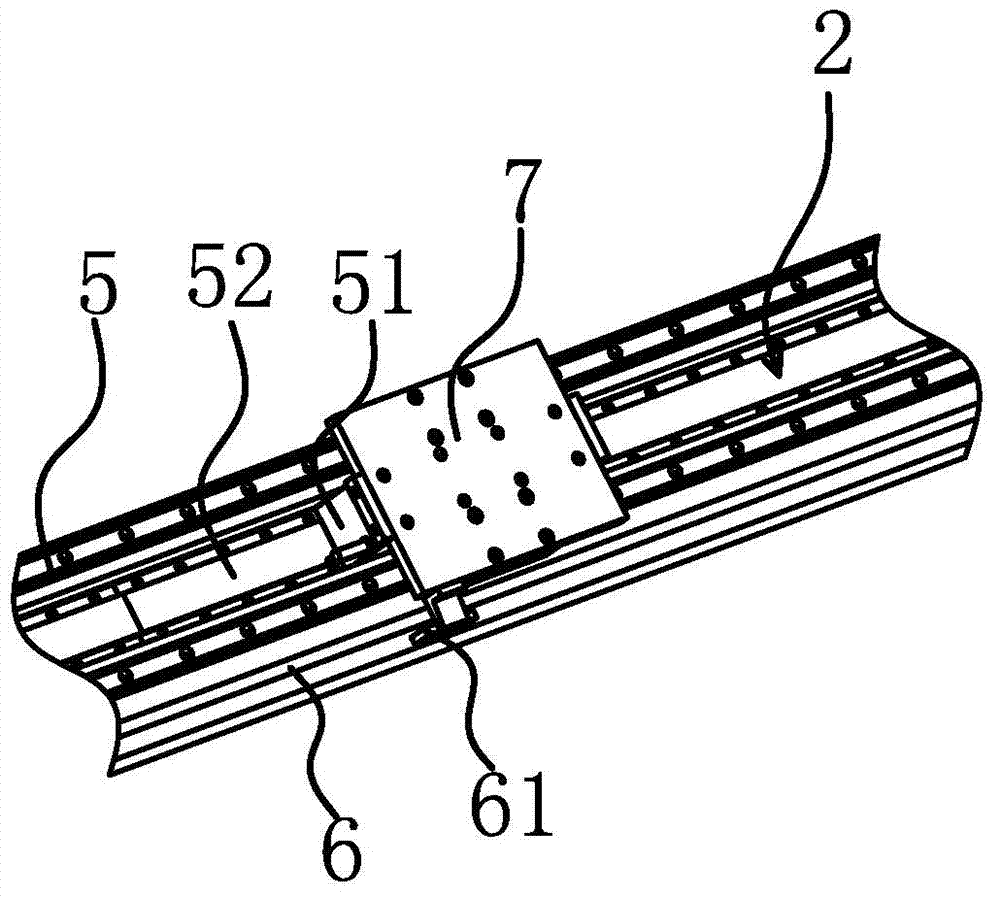

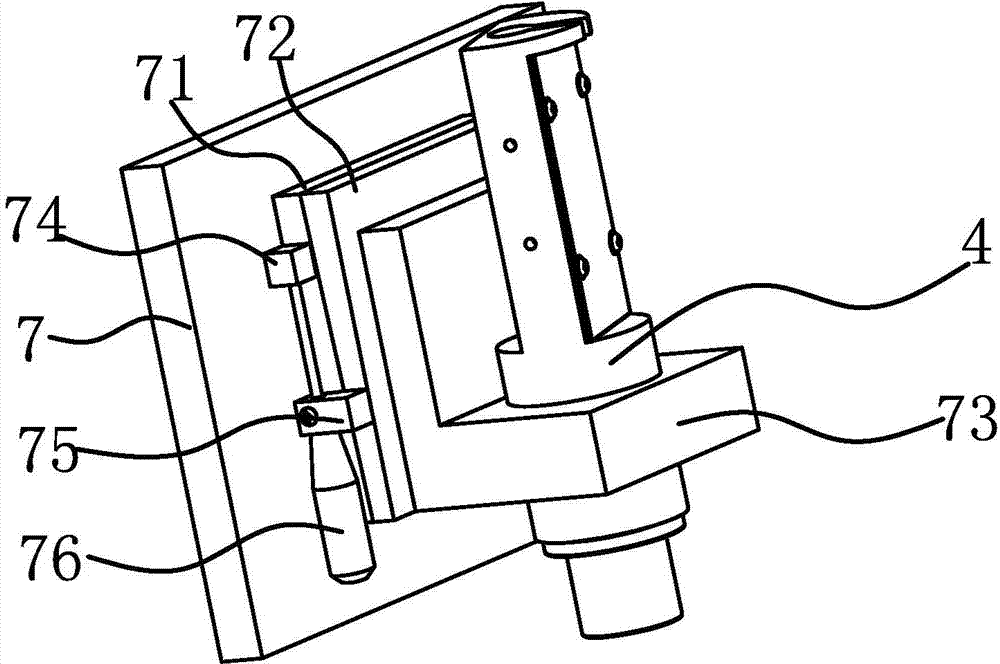

[0026] Such as figure 1 As shown, the laser netting machine includes a frame 1, which is provided with clamps for tensioning the screen and a screen coated with photosensitive glue, and the frame 1 is also provided with a laser 4 capable of emitting laser and a driver. The servo device for horizontal and vertical movement of the laser 4 relative to the screen plate, and the computer pre-installed with the printing spot color separation system and patterns, the laser 4 is connected to the computer and can control the laser 4 to turn on and off, the servo device There is also a position sensor on the top, and the sensor continuously sends position signals to the computer, and the computer can control the laser 4 to turn on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com