Portable core gas logging permeability measuring device

A gas permeability measurement and measurement device technology, which is applied in the field of portable core gas permeability measurement device and core permeability measurement field, can solve the problems of difficult measurement, low data accuracy, inaccuracy, etc., so as to avoid inaccurate measurement. , high measurement efficiency and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

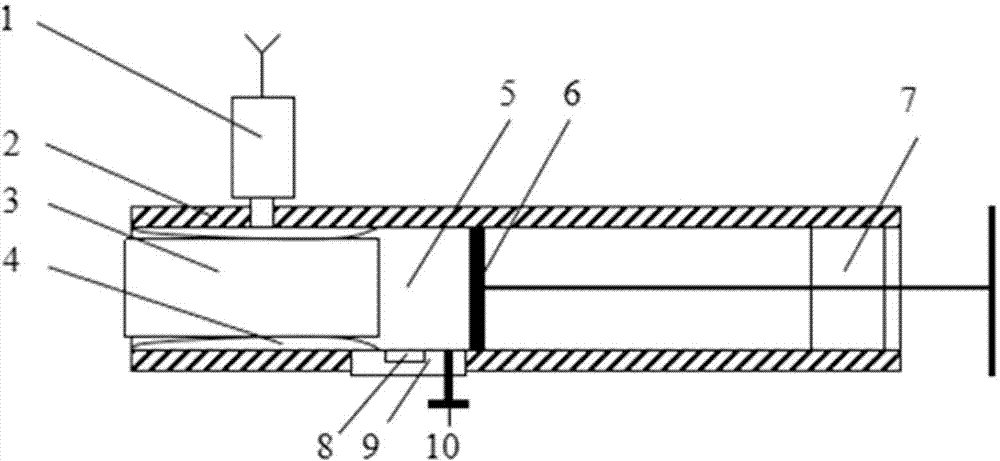

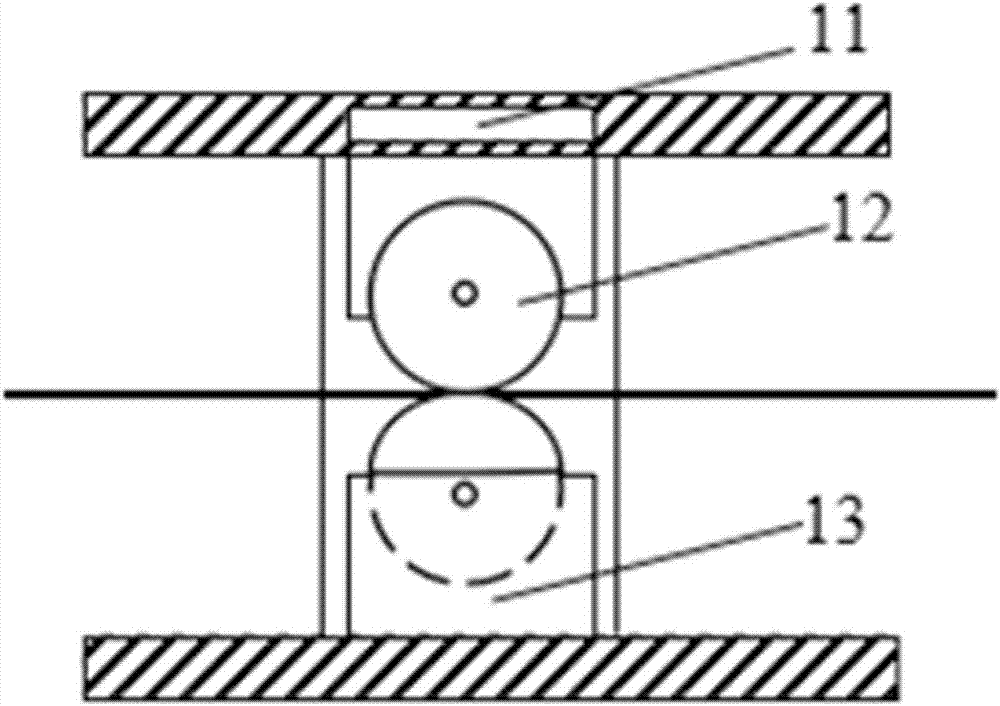

[0114] like figure 1 As shown, a portable rock core gas permeability measuring device, which includes a core 3, a pressure sensor 8, a cylinder 2, a hand hydraulic pump 1, a rubber sleeve 4, a piston 6, a piston driving device 7, a computing chip and a liquid crystal display 9. Vent valve 10. The core 3 is placed in the cylinder body 2, the rubber sleeve 4 is arranged between the core 3 and the cylinder body 2, the hydraulic pump is arranged on the outside of the cylinder body 2, and is connected with the rubber sleeve 4, the The piston 6 and the piston driving device 7 are arranged in the cylinder 2, an inner cavity 5 is formed between one end face of the core 3 and the piston 6, the pressure sensor 8, the computing chip and the liquid crystal display 9 and The vent valve 10 is arranged on the outer side of the cylinder body 2 and is connected with the inner cavity 5 .

[0115] The pressure sensor 8 is embedded in the wall of the cylinder 2 . One end face of the core 3 pro...

Embodiment 2

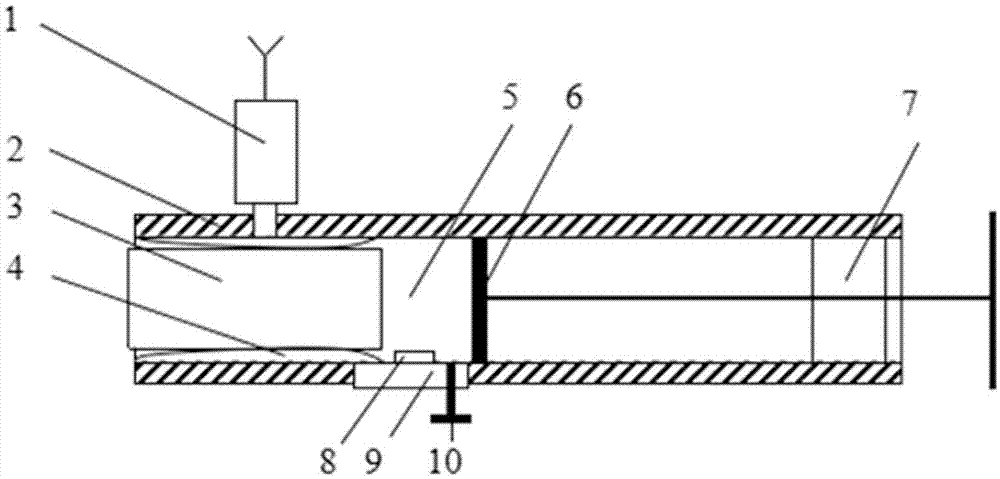

[0144] The portable rock core gas permeability measuring device, the measuring method of rock core gas permeability and the calculation formula and derivation process of rock core gas apparent permeability are the same as those in Embodiment 1, and the difference is: image 3As shown, the pressure sensor in the portable core gas permeability measuring device protrudes from the inner wall of the cylinder. The cylinder is made of stainless steel, the length of the cylinder is 60cm, the wall thickness of the cylinder is 1.0cm, and the thickness of the piston is 3.5cm. The power supply in the piston driving device is a battery, and the battery is placed in a power supply groove embedded in the wall of the cylinder. The length of the core is 3.0cm; the hand-operated hydraulic pump exerts a confining pressure of 0.5MPa on the core; the speed of the uniform motion of the piston is 0.1cm / s.

Embodiment 3

[0146] The portable core gas permeability measurement device, the measurement method of the core gas permeability, and the calculation formula and derivation process of the core gas apparent permeability are the same as those in the first embodiment, except that the cylinder body is made of stainless steel, and the cylinder body is made of stainless steel. The length is 55cm, the wall thickness of the cylinder is 0.8cm, and the thickness of the piston is 4.0cm. The length of the core is 8.0cm; the hand-operated hydraulic pump exerts a confining pressure of 3.0MPa on the core; the speed of the uniform motion of the piston is 0.8cm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com