Dry pulverized coal gasification device

A technology of gasification device and dry coal powder, which is applied in the mechanical details of gasification device, granular/powder fuel gasification, chemical industry, etc. It can achieve the effect of high comprehensive utilization rate of energy, reduction of intermediate heat loss, and reduction of fly ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

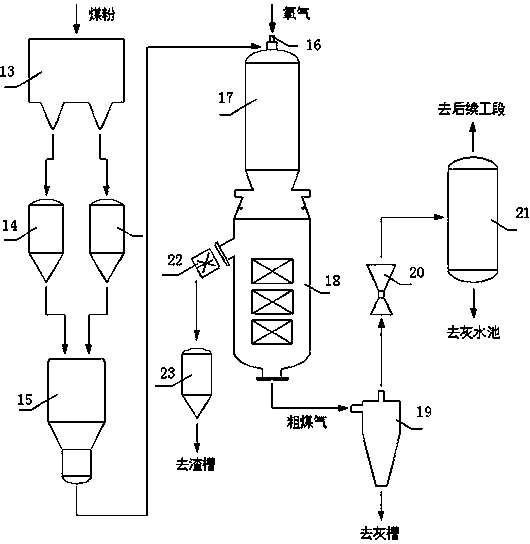

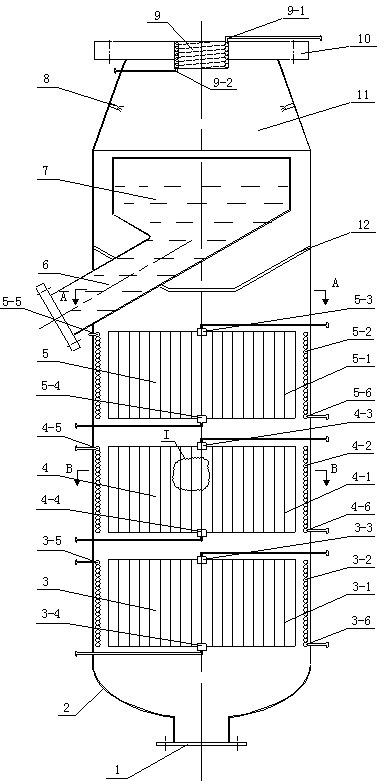

[0043] The invention includes a pulverized coal conveying mechanism, a pressurized gasification mechanism, a coal gas purification mechanism and a slag discharge mechanism. Among them, the pulverized coal delivery mechanism is composed of a pulverized coal storage bin 13, a pulverized coal lock hopper 14, and a pulverized coal delivery tank 15, and the pressurized gasification mechanism is composed of a pulverized coal burner 16, a gasification chamber 17 of a gasifier, and a The recovery device 18 is composed; the gas purification mechanism is composed of a cyclone separator 19, a venturi scrubber 20, and a washing tower 21;

[0044] Process of the present invention is as follows:

[0045] (1) After the raw coal is ground and dried, it enters the pulverized coal silo for storage, and then falls into the pulverized coal lock hopper arranged at the lower part of the silo by its own gravity. The delivery tank adopts the method of discharging from the bottom to carry out pulveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com