Flexible conductive adhesive capable of being used in direct coating manner and preparation method of flexible conductive adhesive

A flexible conductive and coating technology, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems that cannot meet the needs of flexible conductive connections, reduce the conductive performance, and easily destroy the conductive path, and achieve the goal of overcoming Easy to crack, excellent electrical conductivity, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

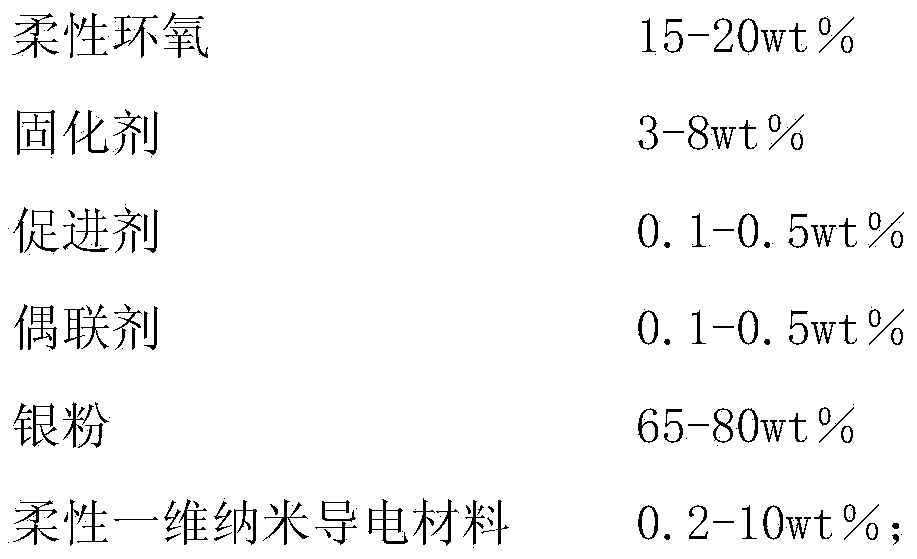

[0036] 1) First weigh the following components:

[0037]

[0038] 2) Fully mix TKM-828, DER732, methylhexahydrophthalic anhydride, 2-ethyl-4-methylimidazole, and KH560 weighed in 1) to obtain a matrix;

[0039] 3) Add the ethanol solution of silver nanowires to the matrix of 2), mix well, and vacuumize for 24 hours to remove ethanol; then add the flake silver powder SF-0340 weighed in 1), mix well, Get a flexible conductive adhesive for direct coating use.

[0040] The silver nanowire ethanol solution used in this embodiment has a length of 15-60 μm, a diameter of 150-350 nm, and a concentration of 0.05 g / ml.

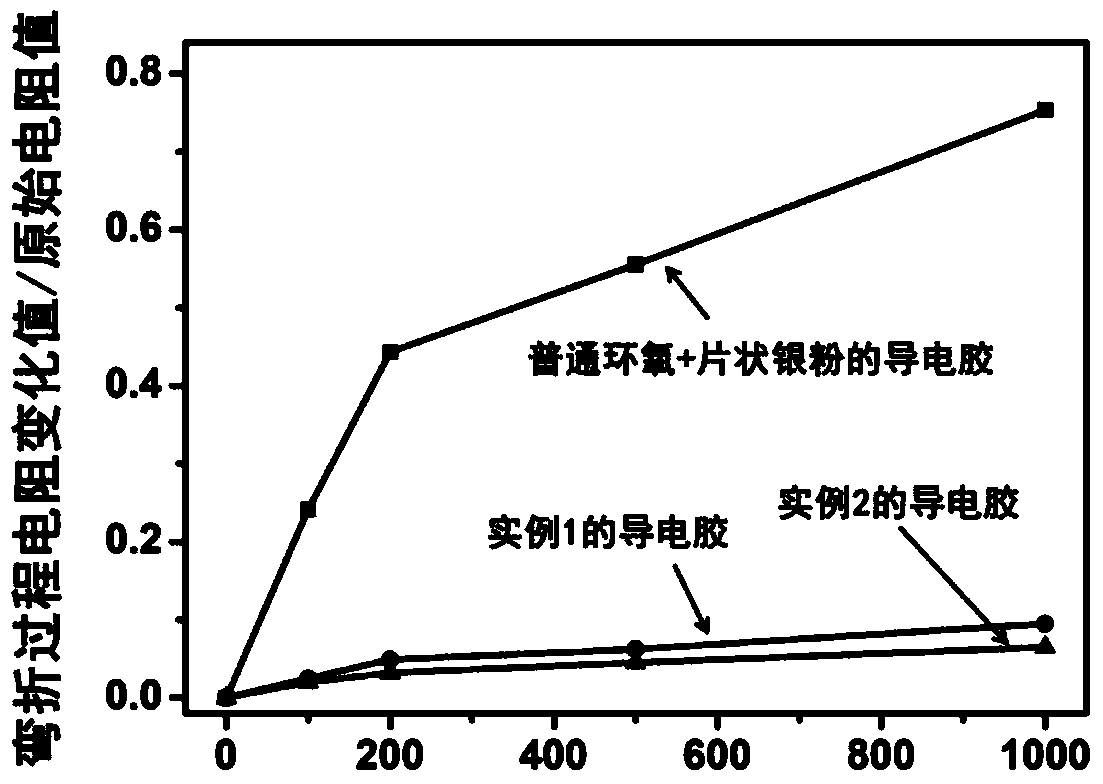

[0041] The flexible conductive adhesive of this embodiment is cured for 2 hours at 150°C, and the resistivity is 6.65×10 -5 Ω·cm, excellent electrical conductivity; and, if figure 1 As shown, the bending resistance of the flexible conductive adhesive is much better than that of the conductive adhesive prepared with ordinary epoxy as the matrix and flake silver pow...

Embodiment 2

[0043] 1) First weigh the following components:

[0044]

[0045] 2) Fully mix the TKM-828, DER732, methyltetrahydrophthalic anhydride, Ni-imidazole complex, and KH550 weighed in 1) to obtain a matrix;

[0046] 3) Add the ethanol solution of copper nanowires to the matrix of 2), mix well, and vacuumize for 24 hours to remove ethanol; then add the flake silver powder SF-0340 weighed in 1), mix well, Get a flexible conductive adhesive for direct coating use.

[0047] The ethanol solution of copper nanowires used in this embodiment has a length of 0.8-6 μm, a diameter of 100-200 nm, and a concentration of 0.2 g / ml.

[0048] The flexible conductive adhesive of this embodiment is cured for 2 hours at 150°C, and the resistivity is 8.56×10 -5 Ω·cm, excellent electrical conductivity; and, if figure 1 As shown, the bending resistance of the flexible conductive adhesive is much better than that of the conductive adhesive prepared with ordinary epoxy as the matrix and flake silver ...

Embodiment 3

[0050] 1) First weigh the following components:

[0051]

[0052] 2) TKM-828, DER732, methyl hexahydrophthalic anhydride, methyl tetrahydrophthalic anhydride, 2-ethyl-4-methylimidazole, 2-ethyl Mix imidazole and KH570 thoroughly to obtain a matrix;

[0053] 3) Add the ethanol solution of gold nanowires to the matrix of 2), mix well, and vacuumize for 24 hours to remove ethanol; then add the flaky silver powder SF-0340 weighed in 1), mix well, Get a flexible conductive adhesive for direct coating use.

[0054] The ethanol solution of gold nanowires used in this embodiment has a length of 3-6 μm, a diameter of 20-50 nm, and a concentration of 0.1 g / ml.

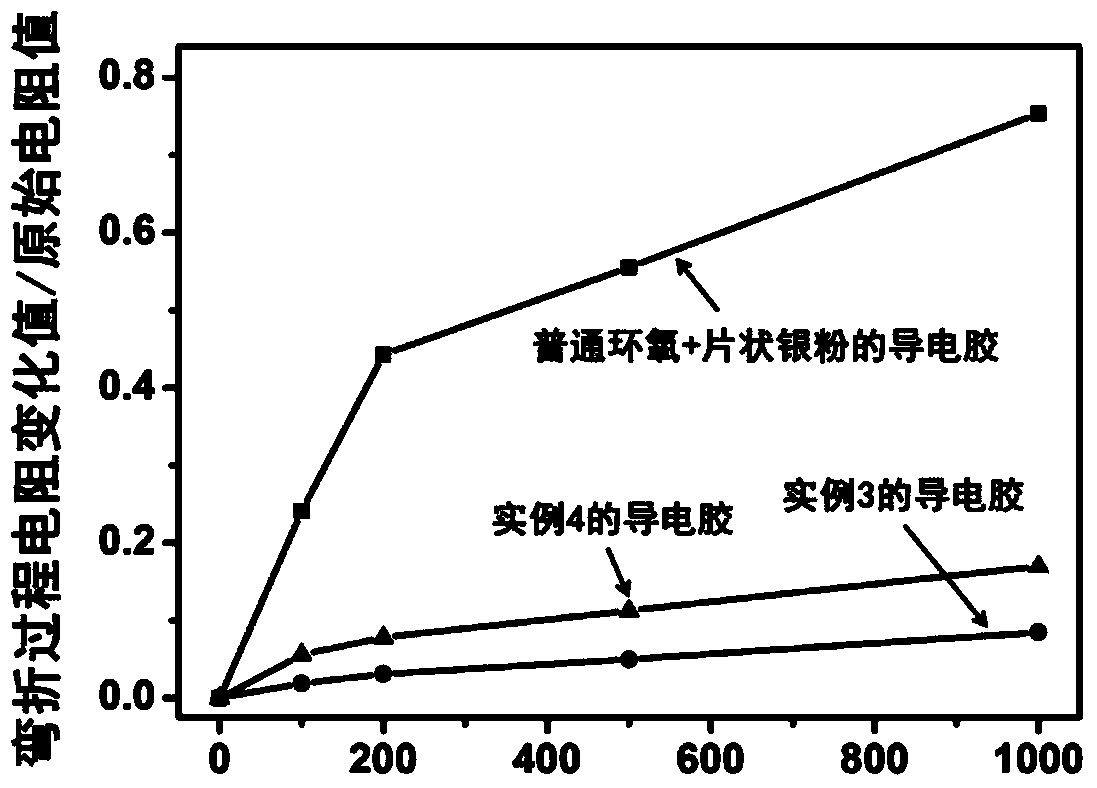

[0055] The flexible conductive adhesive of this embodiment is cured for 2 hours at 150°C, and the resistivity is 7.83×10 -5 Ω·cm, excellent electrical conductivity; and, if figure 2 As shown, the bending resistance of the flexible conductive adhesive is much better than that of the conductive adhesive prepared with ordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com