Microelement-rich liquid urea ammonium nitrate solution fertilizer and preparation method thereof

A liquid urea and trace element technology, which is applied in ammonium nitrate fertilizer, ammonium salt fertilizer, nitrate fertilizer and other directions, can solve the problems of single element and can not meet nutritional elements, etc., and achieves low raw material cost, prolongs nitrogen fertilizer effect, and improves fertilizer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

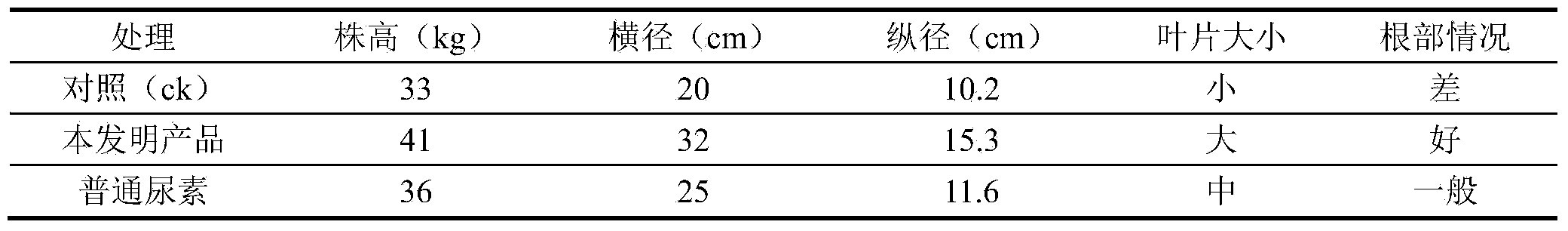

Image

Examples

Embodiment 1

[0026] (1) Add 130kg of pure water to the enamel reaction kettle, the temperature is controlled at 80°C, add 484kg of urea to it, stir at a constant speed for 30min, and make a urea solution;

[0027] (2) Add 130kg of water in the enamel reaction kettle, the temperature is controlled at 100°C, add 595kg of ammonium nitrate therein, stir at a constant speed for 30min, and make an ammonium nitrate solution;

[0028] (3) Mix urea solution and ammonium nitrate solution evenly according to the formula ratio, and stir for 30 minutes;

[0029] (4) Add 2kg liquid ammonia, 1.5kg magnesium nitrate, 1kg ammonium bicarbonate to the above mixed solution, 0.6kg polyaspartic acid mass fraction is 50% polyaspartic acid sodium (polymerization degree 200), stir 30min, The above substances have anti-corrosion and scale-inhibiting effects;

[0030] (5) Add 1 kg of urease inhibitor to the above mixed solution: N-methyl-2-pyrrolidone, and stir for 20 minutes;

[0031] (6) 13kg of citric acid was ...

Embodiment 2

[0041] (1) Add 80kg of pure water to the enamel reaction kettle, the temperature is controlled at 100°C, add 286kg of urea to it, stir at a constant speed for 60min, and make a urea solution;

[0042] (2) Add 70kg of water to the enamel reaction kettle, the temperature is controlled at 130°C, add 387kg of ammonium nitrate to it, stir at a constant speed for 60min, and make an ammonium nitrate solution;

[0043] (3) Mix urea solution and ammonium nitrate solution evenly according to the formula ratio, and stir for 60 minutes;

[0044] (4) Add 0.4kg of liquid ammonia, 0.6kg of magnesium nitrate, 0.2kg of ammonium bicarbonate, 0.1kg of sodium polyaspartate (polymerization degree 200) to the above mixture, and stir for 30-60min. Effect;

[0045] (5) Add 0.3 kg of urease inhibition to the above mixed solution: N-methyl-2-pyrrolidone, and stir for 20 min;

[0046](6) Add 4kg of citric acid to the above mixed solution, and the reaction temperature is controlled at 150°C;

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com