Ceramic composite for light conversion and light-emitting device using same

A light-emitting device and composite technology, which is applied in the application of gas discharge lamps, light-emitting materials, electric solid-state devices, etc., can solve the problem of uneven light, and achieve excellent heat resistance, high output, and suppression of uneven light emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

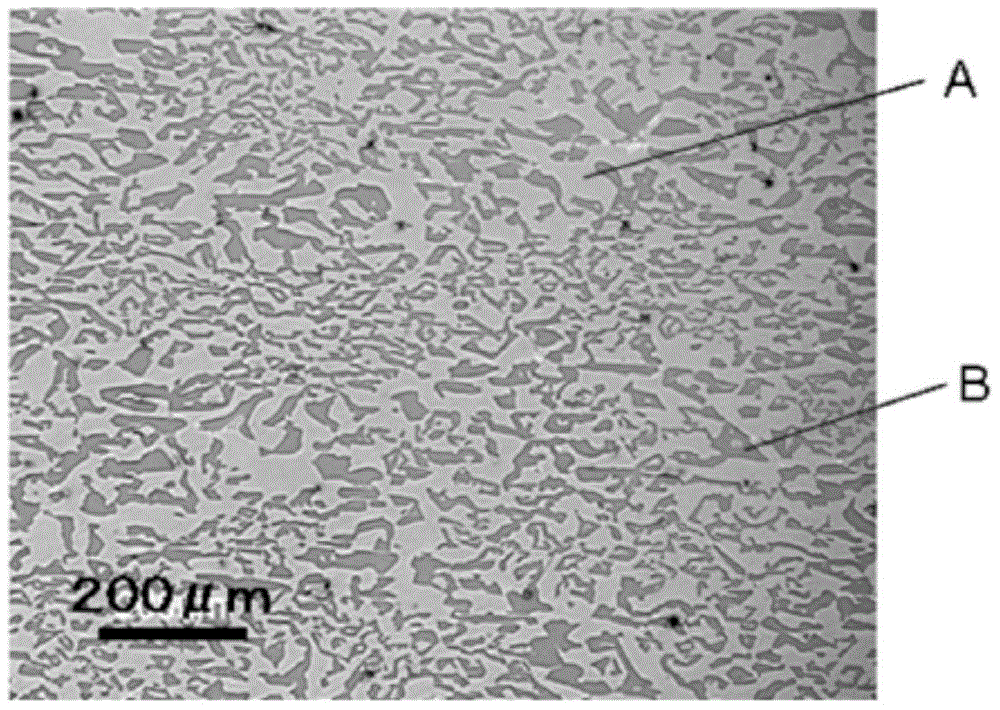

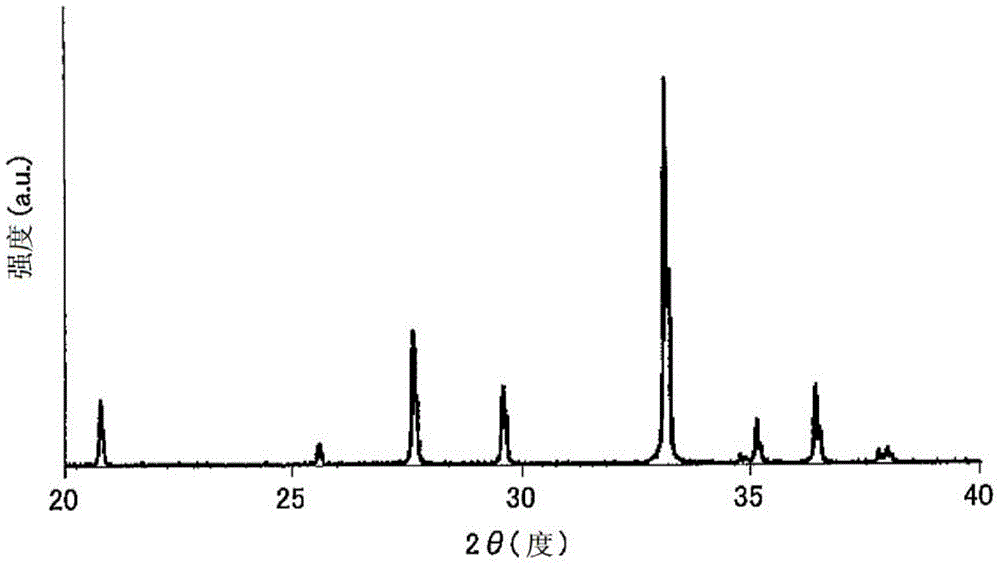

[0098] Weigh in AlO 3 / 2 Converted to 0.773 moles of α-Al 2 o 3 Powder (purity 99.99%), with TbO 7 / 4 Converted to 0.227×0.997 moles of Tb 4 o 7 Powder (purity 99.9%), 0.227 x 0.003 moles of CeO 2 Powder (purity 99.9%). After the powder was wet-mixed in ethanol by a ball mill for 16 hours, the ethanol was removed using an evaporator to obtain a raw material powder. The raw material powder is pre-melted in a vacuum furnace to obtain a unidirectionally solidified raw material.

[0099] Then, this raw material was directly put into a molybdenum crucible, and it was designed to be unidirectionally solidified by providing a melting holding zone in the upper part and a cooling zone in the lower part with a temperature gradient of 50°C / cm in the vertical direction (solidification direction). The melt holding area of the device, at 1.33 x 10 -3 Pa(10 -5 The raw material is melted under the pressure of Torr). Then, under the same environment, the molybdenum crucible is lowere...

Embodiment 2

[0105] α-Al 2 o 3 Powder (purity 99.99%) with AlO 3 / 2 Converted to 0.773 moles, Tb 4 o 7 Powder (purity 99.9%) with TbO 7 / 4 Converted to 0.227×0.994 mol, CeO 2 The raw material was weighed so that the powder (purity: 99.9%) was 0.227×0.006 mol. A ceramic composite for light conversion of Example 2 was obtained in the same manner as in Example 1 except that the moving speed of the molybdenum crucible was 10 mm / hr. By the same method as in Example 1, it was confirmed that the photoconverting ceramic composite of Example 2 was made of Tb activated by Ce. 3 Al 5 o 12Phase and Al 2 o 3 constituted by phase. Table 1 shows the dominant fluorescence wavelength and relative fluorescence intensity of the obtained ceramic composite for light conversion.

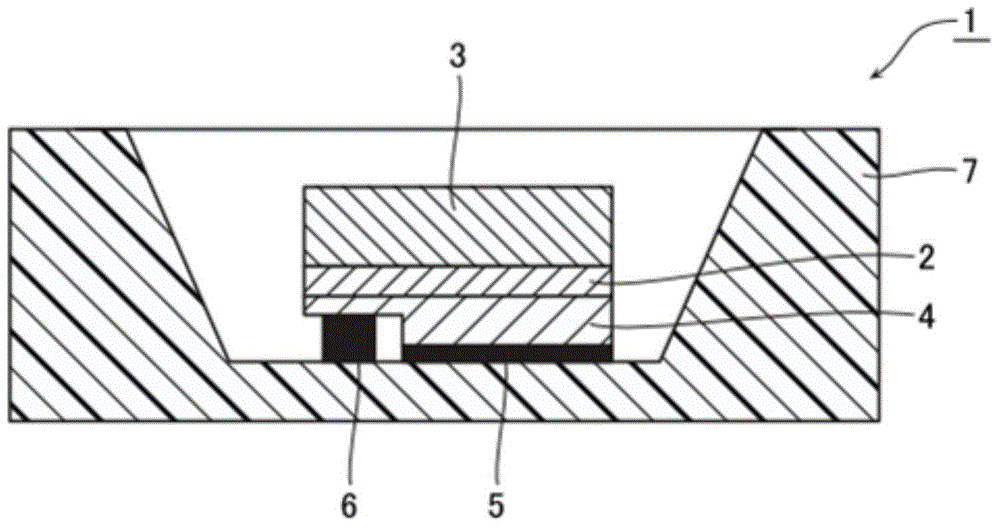

[0106] In addition, except that the thickness of the flat plate-shaped ceramic composite for light conversion was set to 0.14, 0.19, and 0.24 mm, a light-emitting device was produced for each thickness of the ceramic composi...

Embodiment 3

[0108] Weigh in AlO 3 / 2 Converted to 0.773 moles of α-Al 2 o 3 Powder (purity 99.99%), with TbO 7 / 4 Converted to 0.227×0.99 moles of Tb 4 o 7 Powder (purity 99.9%), 0.227×0.01 mol of CeO 2 Powder (purity 99.9%). A ceramic composite for light conversion was obtained by the same method as in Example 1 except that the moving speed of the molybdenum crucible was 10 mm / hr. By the same method as in Example 1, it was confirmed that the photoconverting ceramic composite of Example 3 was made of Tb activated by Ce. 3 al 5 o 12 Phase and Al 2 o 3 constituted by phase. Table 1 shows the dominant fluorescence wavelength and relative fluorescence intensity of the obtained ceramic composite for light conversion.

[0109] In addition, except that the thickness of the flat plate-shaped ceramic composite for light conversion was set to 0.10, 0.15, and 0.19 mm to produce a light-emitting device, the same method as in Example 1 was used to determine the thickness of the flat plate sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com