Compact high-power speed reduction gear ring for starting machine of diesel vehicle

A starter, compact technology, applied in the direction of engine components, machine/engine, engine starting, etc., can solve the problems of weight increase, development limitation, cost increase, etc., and achieve the goal of reducing volume, optimizing wall thickness, and optimizing height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

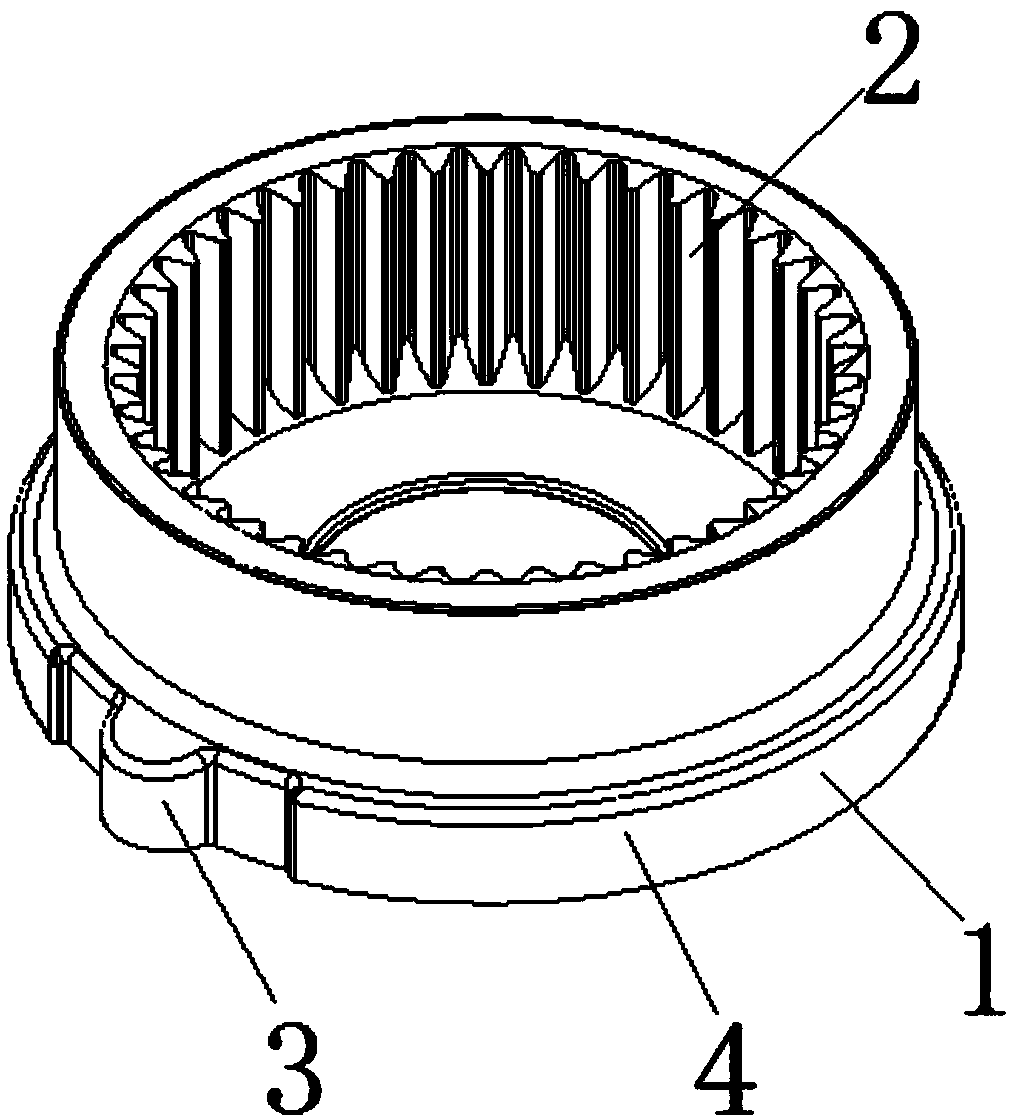

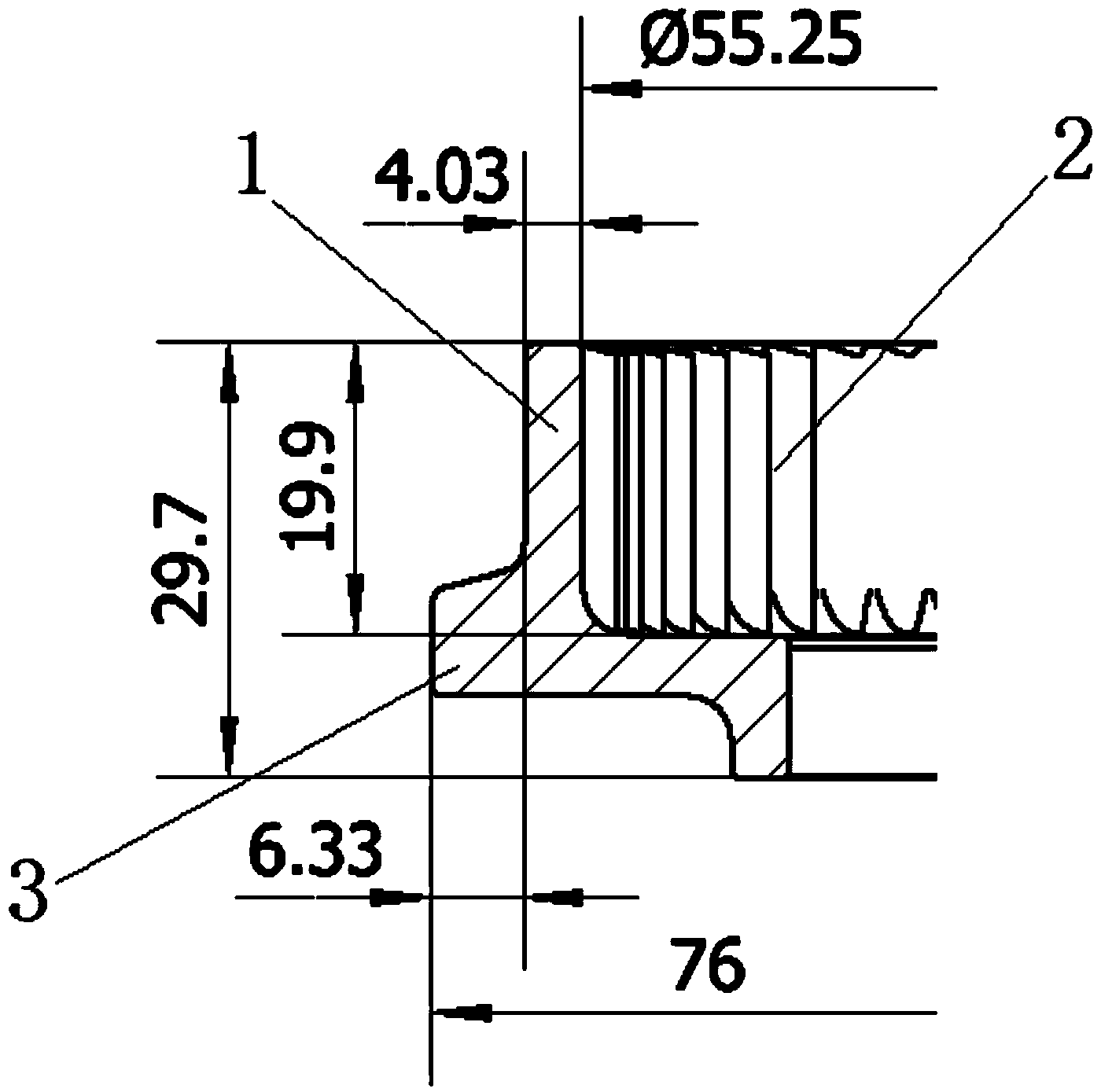

[0016] Such as figure 1 , 2 As shown, the ring gear body 1 of the existing powder metallurgy deceleration ring gear is provided with a deceleration tooth 2, and the ring gear body 1 is provided with a full ring flange edge 4, and the flange edge 4 is provided with a positioning rib 3, and the ring gear body 1 The thickness (wall thickness) is 4mm, and the thickness of the flange side 4 and the positioning rib 3 is 6.33mm.

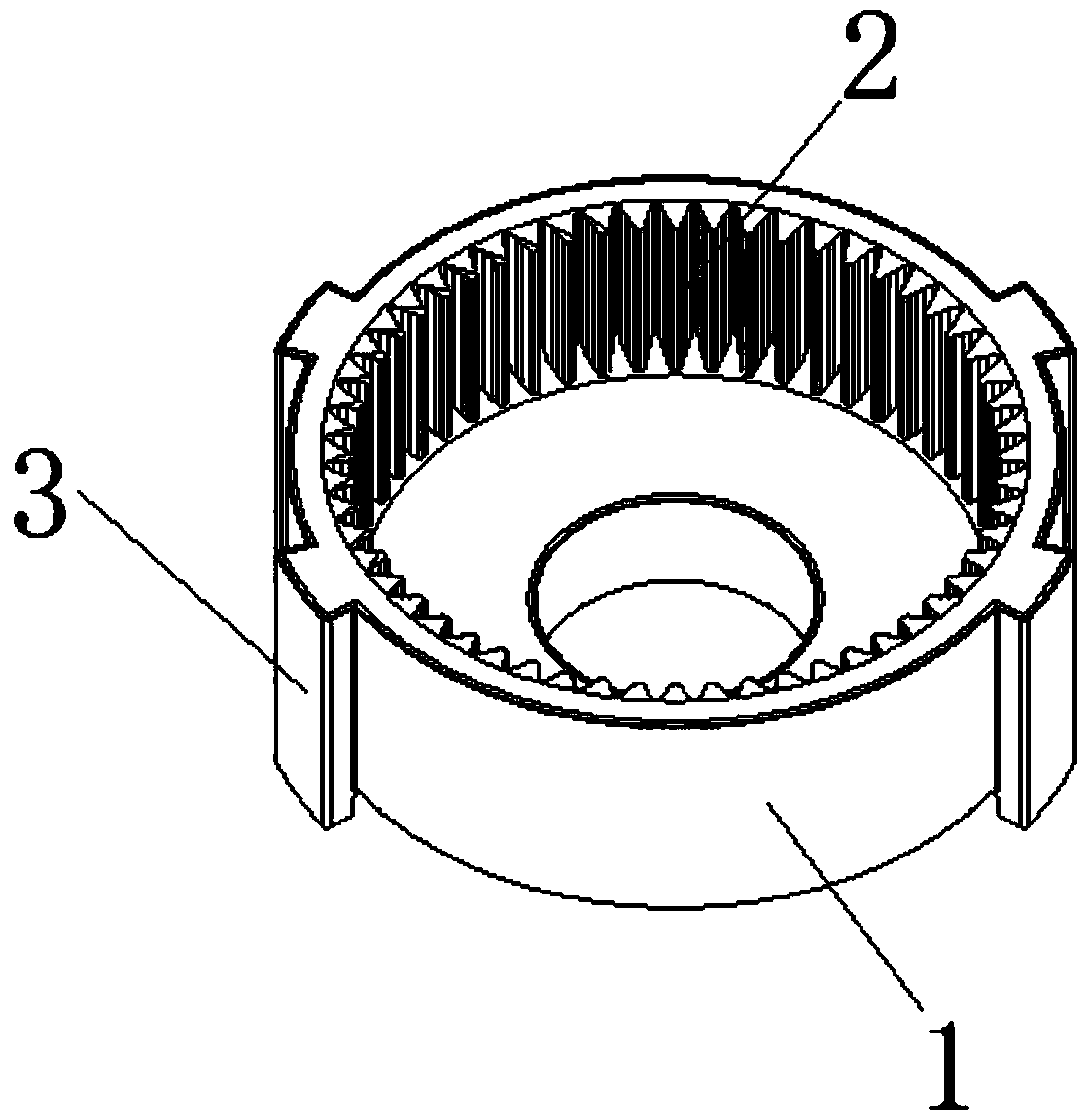

[0017] Such as image 3 , 4 As shown, the deceleration ring gear of the present invention cancels the whole ring flange 4, the thickness of the ring gear body 1 is changed to 3.2mm, and there are four strip-shaped positioning ribs 3 evenly distributed outside the ring gear body 1, and the positioning ribs 3 protrude from the teeth. Circle the bottom of the body 1 . The thickness of the positioning rib 3 is 2.74 mm, and the width of the positioning rib 3 is increased to 9 mm to increase the positioning contact area.

[0018] In general, the outer diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com