Drawing device and method for small-batch multi-variety high-uniformity glass tubes

A glass tube and multi-variety technology, applied in the vertical drawing of molten glass, glass forming, glass manufacturing equipment, etc., can solve the problem that large-scale industrialized production methods cannot be adopted, the pipe diameter and wall thickness cannot be effectively guaranteed, and the operation Workers' skill requirements are extremely high, to achieve the effect of increasing residence time and heat exchange area, accelerating exchange and flow, accelerating flow and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

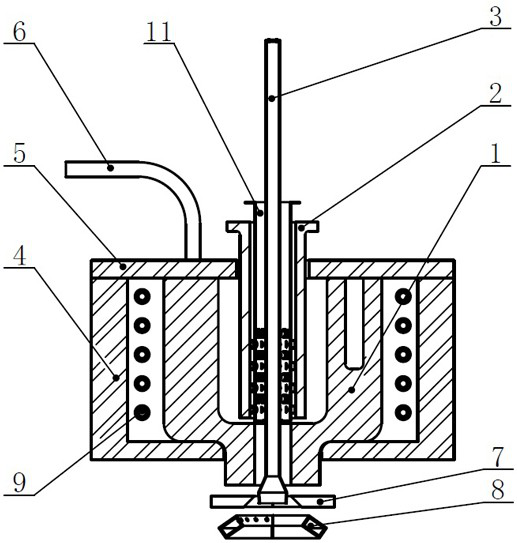

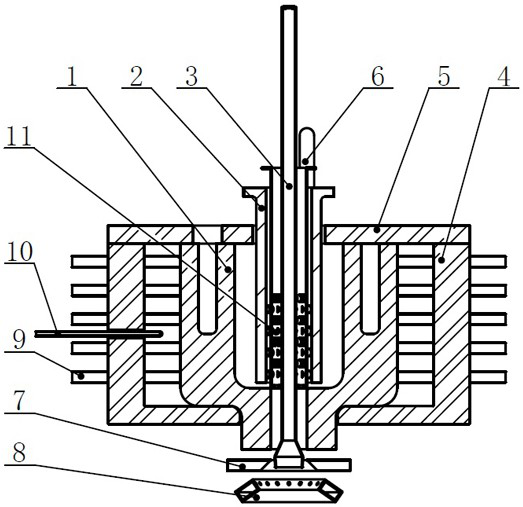

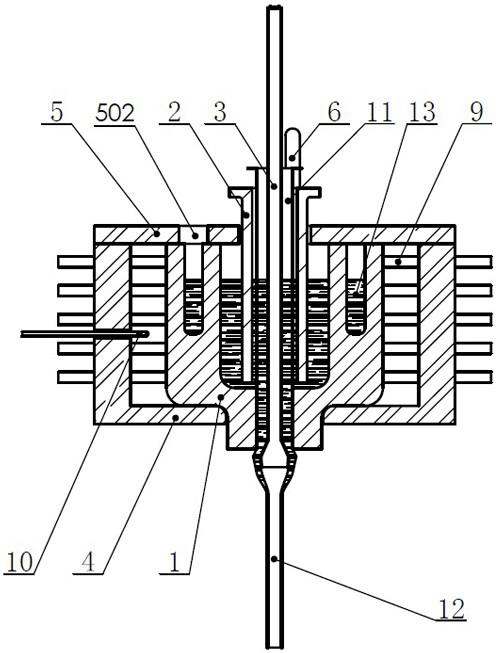

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

[0054] Such as Figure 1 to Figure 9 shown. An embodiment of a small-batch, multi-variety and high-uniformity glass tube drawing device of the present invention, the structure includes: material basin 1, uniform material cylinder 2, mandrel 3, furnace wall 4, cover plate 5, introduction pipe 6, ring Water seal 7, ring burner 8, heating rod 9, thermocouple 10 and stirrer 11. Wherein, the furnace wall 4, the cover plate 5, the heating rod 9 and the thermocouple 10 constitute a molding furnace body. The mandrel 3, the annular water seal 7 and the annular burner 8 constitute the forming part. The uniform material cylinder 2 and the agitator 11 are placed in the cavity of the material basin 1, and the lower edge of the uniform material cylinder 2 and the agitator 11 is provided with a gap with the inner bottom surface of the material basin 1. match.

[0055] Furnace wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com