Structural design method of rolling ball bearing

A rolling ball bearing and structural design technology, applied in the field of mechanical design and manufacturing, can solve the problems of long cycle, time-consuming and labor-intensive, ignoring constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

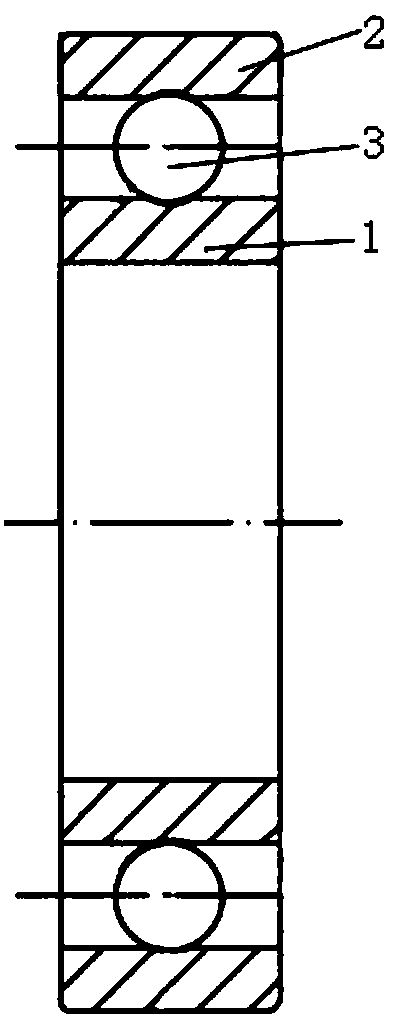

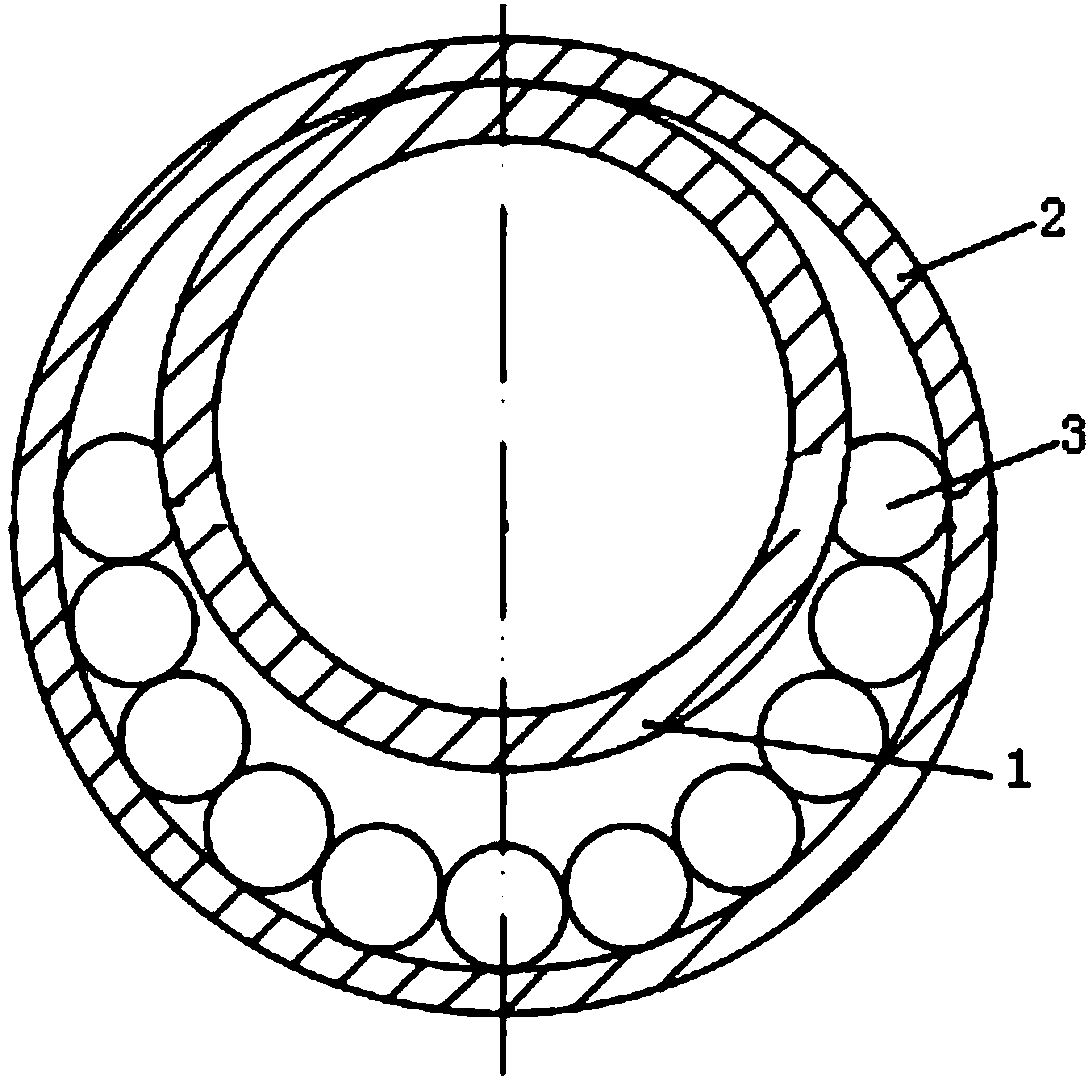

[0071] For the design of 6209 deep groove rolling ball bearings, the basic structural dimensions of the bearing are: the outer diameter of the bearing outer ring 2: D = 85mm, the inner diameter of the bearing inner ring 1: d = 45mm, and the bearing width: w = 19mm.

[0072] 1) Design variables for matlab programming:

[0073] X=[D b ,D m , Z, f i , f o , K Dmax , K Dmin ,ε,e,β] T =[x 1 , x 2 , x 3 , x 4 , x 5 , x 6 , x 7 , x 8 , x 9 , x 10 ] T

[0074] 2) In the design of bearings, the objective function is determined for the purpose of obtaining the longest life:

[0075]

[0076] in

[0077]

[0078] in α = 0 in 6209 deep groove rolling ball bearings.

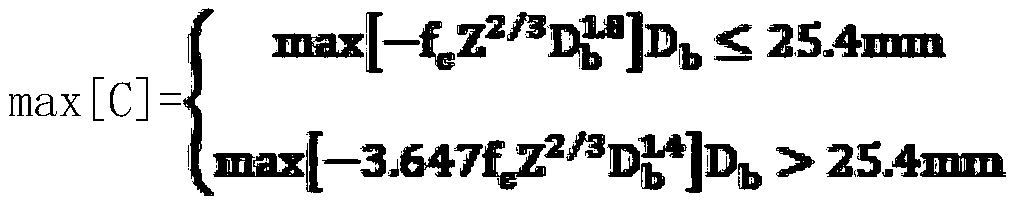

[0079] 3) According to the constraints formed by the bearing structure, assembly and service load conditions, the inequalities obtained are as follows:

[0080]

[0081] g 2 (x)=-(2x 1 -x 7 (D-d))≤0

[0082] g 3 (x)=-(x 6 (D-d)-2x 1 )≤0

[0083] g 4 (x)=-(x 2 -(0.5-x 9 )(D+d))≤0

[...

Embodiment 2

[0102] For the design of 7008C angular contact bearings, the basic structural dimensions of the bearings are D=68mm, d=40mm, w=15mm.

[0103] 3) Design variables for matlab programming:

[0104] X=[D b ,D m , Z, f i ,fo,K Dmax , K Dmin ,ε,e,β] T =[x 1 , x 2 , x 3 , x 4 , x 5 , x 6 , x 7 , x 8 , x 9 , x 10 ] T

[0105] 4) In the design of bearings, the objective function is determined for the purpose of obtaining the longest life:

[0106]

[0107] in

[0108]

[0109] in In 6209 deep groove ball bearings, α=15°.

[0110] 3) According to the constraints formed by the bearing structure, assembly and service load conditions, the inequalities obtained are as follows:

[0111]

[0112] g 2 (x)=-(2x 1 -x 7 (D-d))≤0

[0113] g 3 (x)=-(x 6 (D-d)-2x 1 )≤0

[0114] g 4 (x)=-(x 2 -(0.5-x 9 )(D+d))≤0

[0115] g 5 (x)=-((0.5+x 9 )(D+d)-x 2 )≤0

[0116]

[0117] g 7 (x)=-(0.5(D-x 2 -x 1 )-x 9 x 1 )≤0

[0118] g 8 (x)=-(x 10 w-x 1 )≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com