Degradable quick-forming PET/PBS (polyethylene terephthalate/phosphate buffer solution) alloy and preparation method thereof

A technology of alloy and nucleating agent, which is applied in the field of rapid forming PET/PBS alloy and its preparation, and degradable, which can solve the problem of PET’s high strength, high modulus, high thermal deformation, difficulty in taking advantage of two phases, and deterioration of materials Performance and other issues, to achieve the effect of biodegradability, flexibility, and improved crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

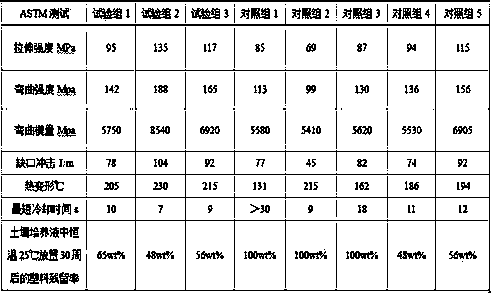

Examples

Embodiment 1

[0023] Example 1 Preparation of a degradable and rapid-forming PET / PBS alloy of the present invention (1)

[0024] Composition: 100 parts of PET, 20 parts of PBS, 3 parts of ethylene-acrylic acid sodium salt Aclyn285, 2 parts of EPDM-g-GMA, 15 parts of alkali-free long fiber, 0.5 part of cyclobutylene terephthalate; the PET The intrinsic viscosity of the PBS is 0.70dL / g, and the intrinsic viscosity of the PBS is 1.0 dL / g.

[0025] Preparation process: dry the PET at 110°C for 6 hours, put PET, PBS, ethylene-acrylic acid sodium salt Aclyn285, EPDM-g-GMA, cyclobutylene terephthalate into a high-speed mixer Mixing for 4 minutes; adding the mixed material into the hopper of the twin-screw extruder, adding the alkali-free long fiber from the glass fiber port, extruding through melt blending, drawing, then water cooling, drying, and pelletizing; The rotating speed of the twin-screw extruder is 400r / min, and the temperature of each zone of the twin-screw extruder is controlled at 2...

Embodiment 2

[0026] Example 2 Preparation of a degradable and rapid-forming PET / PBS alloy of the present invention (2)

[0027] Composition: 100 parts of PET, 40 parts of PBS, 5 parts of sodium acetoacetate, 3 parts of POE-g-MAH, 30 parts of alkali-free long fiber, 1 part of cyclobutylene terephthalate; the intrinsic viscosity of the PET It is 0.80dL / g, and the intrinsic viscosity of described PBS is 1.2 dL / g.

[0028] Preparation process: dry the PET at 120°C for 5 hours, put PET, PBS, sodium acetoacetate, POE-g-MAH, and cyclobutylene terephthalate into a high-speed mixer and mix for 4 minutes; Add the mixed material into the hopper of the twin-screw extruder, add the alkali-free long fiber from the glass fiber port, melt and blend, extrude, draw strands, then water-cool, dry, and pelletize; the twin-screw The rotating speed of the extruder is 300r / min, and the temperature of each zone of the twin-screw extruder is controlled at 250°C.

Embodiment 3

[0029] Example 3 Preparation of a degradable and rapid-forming PET / PBS alloy of the present invention (3)

[0030] Composition: 100 parts of PET, 20 parts of PBS, 5 parts of ethylene-acrylic acid sodium salt Aclyn285, 2 parts of POE-g-MAH, 30 parts of alkali-free long fiber, 0.5 part of cyclobutylene terephthalate; the PET The intrinsic viscosity of the PBS is 0.75dL / g, and the intrinsic viscosity of the PBS is 1.1dL / g.

[0031] Preparation process: Dry the PET at 110°C for 5 hours, put PET, PBS, ethylene-acrylic acid sodium salt Aclyn285, POE-g-MAH, and cyclobutylene terephthalate into a high-speed mixer Mixing for 3 minutes; adding the mixed material into the hopper of the twin-screw extruder, adding the alkali-free long fiber from the glass fiber port, extruding through melt blending, drawing, then water cooling, drying, and pelletizing; The rotational speed of the twin-screw extruder is 200r / min, and the temperature of each zone of the twin-screw extruder is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com