A kind of amphiphilic comb composite polymer light stabilizer and preparation method thereof

A light stabilizer and polymer technology, applied in the field of amphiphilic comb-shaped composite polymer light stabilizer and its preparation, can solve the problems of poor compatibility of wood-plastic composite materials, loss of light stabilization effect, and the like, Achieve the effect of being beneficial to transportation and storage, improving poor compatibility and high thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

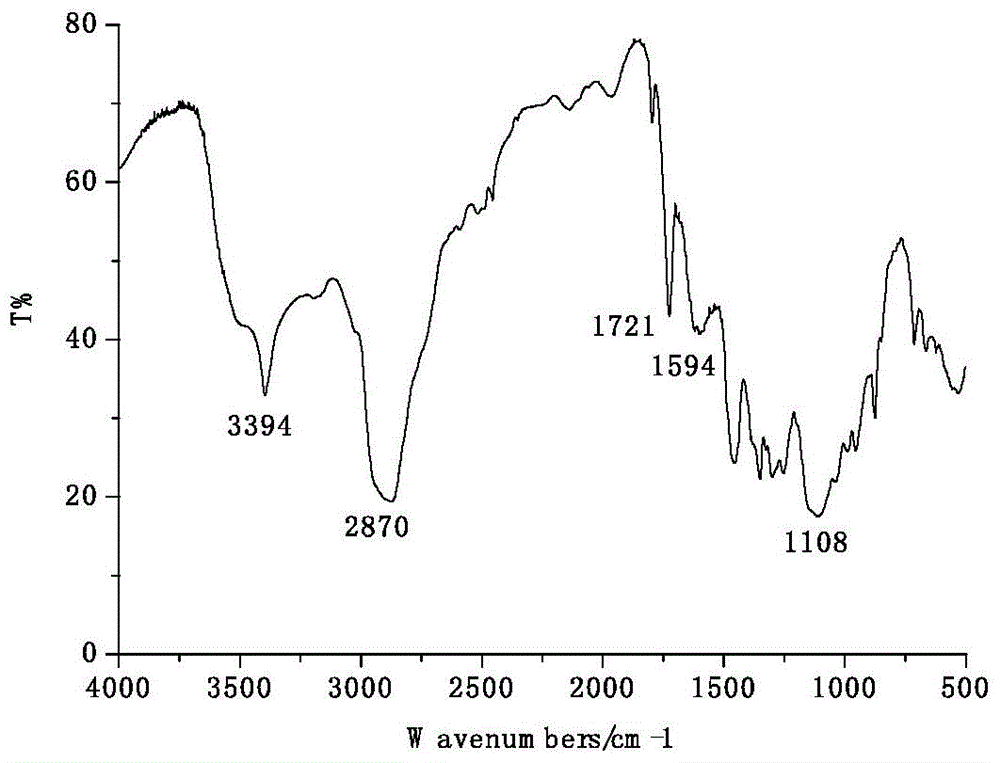

Image

Examples

preparation example Construction

[0105] A preparation method of an amphiphilic comb-shaped composite polymer light stabilizer includes the following steps:

[0106] Step 1. Provide and / or prepare intermediate I of formula V

[0107]

[0108] Where R 1 When it is H, the intermediate I is fumaric acid 2,2,6,6-tetramethylpiperidinol polyethylene glycol monomethyl ether diester;

[0109] R 1 For CH 3 When the intermediate I is fumaric acid 1,2,2,6,6-pentamethylpiperidinol polyethylene glycol monomethyl ether diester;

[0110] n=13, 22, 26, 45;

[0111] Step two, provide and / or prepare intermediate II of formula VI

[0112]

[0113] Where R 2 For H, R 3 When it is H, the intermediate II is 2-hydroxy-4 acrylate benzophenone;

[0114] R 2 For H, R 3 When it is COOH, the intermediate II is 2'-carboxy-2-hydroxy 4-acrylate benzophenone:

[0115] R 2 For CH 3 , R 3 When it is H, the intermediate II is 2-hydroxy-4-methacrylate benzophenone;

[0116] R 2 For CH 3 , R 3 When it is COOH, the intermediate II is 2'-carboxy-2-hydroxy 4-meth...

Embodiment 1

[0138] The amphiphilic comb-shaped composite polymer light stabilizer of the present invention has the general structural formula:

[0139]

[0140] Where R 0 Is C 18 ;

[0141] R 1 Is H;

[0142] R 2 Is H;

[0143] R 3 Is H;

[0144] n=26, which is polyethylene glycol monomethyl ether 1200

[0145] The value of x is any integer ranging from 1 to 100;

[0146] The value of y is any integer ranging from 1 to 100;

[0147] The value of z is an arbitrary integer from 1 to 100.

[0148] The preparation method of the amphiphilic comb-shaped composite polymer light stabilizer of the present invention includes the following steps:

[0149] Step 1. Provide and / or prepare intermediate I;

[0150] Specifically:

[0151] a. Feed monomethyl fumarate and polyethylene glycol monomethyl ether at a molar ratio of 1:1.1, add 2 times the volume of the mixture of toluene solvent, heat to 45°C and stir to dissolve, then add 3.5% of the total weight of the mixture The temperature of p-toluenesulfonic acid is incr...

Embodiment 2

[0165] The amphiphilic comb-shaped composite polymer light stabilizer of the present invention has the general structural formula:

[0166]

[0167] Where R 0 Is C 4 ;

[0168] R 1 Is H;

[0169] R 2 Is H;

[0170] R 3 Is H;

[0171] n=26, which is polyethylene glycol monomethyl 1200;

[0172] The value of x is any integer ranging from 1 to 100;

[0173] The value of y is any integer ranging from 1 to 100;

[0174] The value of z is an arbitrary integer from 1 to 100.

[0175] The preparation method of the amphiphilic comb-shaped composite polymer light stabilizer of the present invention includes the following steps:

[0176] Step 1. Provide and / or prepare intermediate I;

[0177] Specifically:

[0178] a. Feed monomethyl fumarate and polyethylene glycol monomethyl ether at a molar ratio of 1:1.05, add 4 times the volume of the mixture of toluene solvent, heat to 45°C and stir to dissolve, then add 3.5% of the total weight of the mixture The p-toluenesulfonic acid is heated to 100°C, protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com