Reformer of methanol-water hydrogen manufacturing equipment, and manufacturing technology of reformer

A technology of hydrogen production equipment and manufacturing process, applied in the field of methanol water hydrogen production equipment, can solve the problems of heat energy loss, easy corrosion, reduced performance and service life, etc., and achieve the effects of low surface temperature, good insulation, and good heat preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

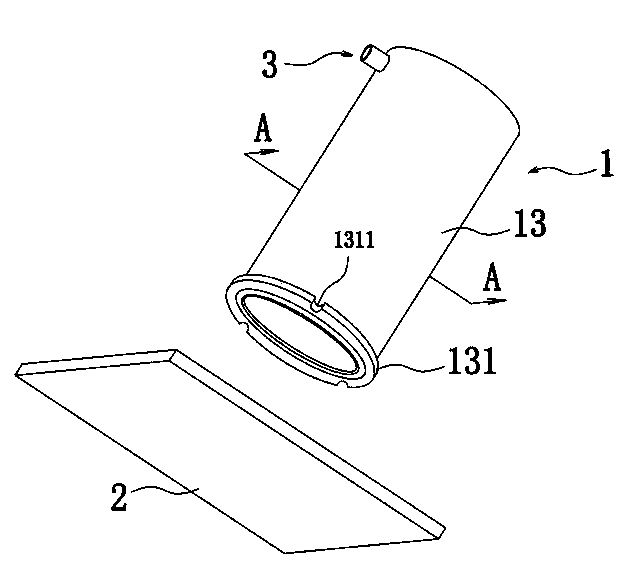

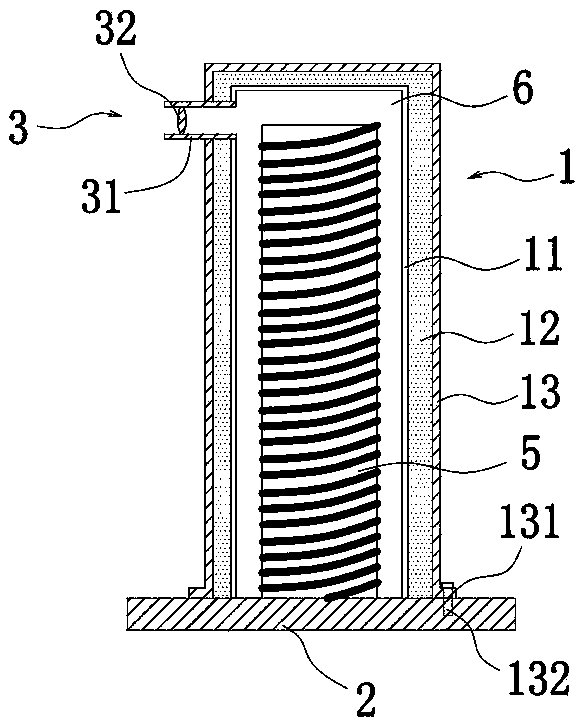

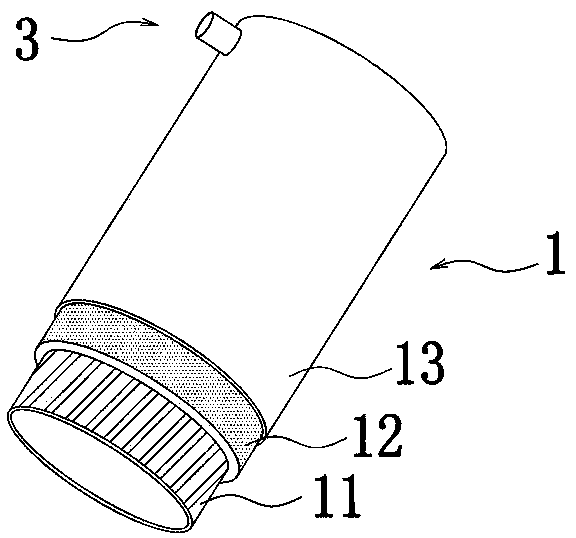

[0041] Such as Figure 1 to Figure 4 As shown, a reformer of methanol-water hydrogen production equipment is provided with a reforming chamber 5 and a combustion chamber 6 in the reformer. In the reforming chamber 5, under the action of a catalyst, methanol cracking reaction and carbon monoxide generation occur. The conversion reaction generates hydrogen and carbon dioxide, and the temperature in the reforming chamber 5 is between 350-409°C; in the combustion chamber 6, the hydrogen burns to provide heat for the reforming chamber 5, and the temperature in the combustion chamber 6 is 405-570 between ℃. The reformer includes a reformer shell 1, which sequentially includes a stainless steel inner shell 11, an insulating cotton layer 12, and a mica shell 13 from the inside to the outside, and the reformer shell 1 and the stainless steel inner shell The diameter-thickness ratio of the shell 11 is 150:0.8-150:2.5, the diameter-thickness ratio of the reformer shell 1 and the insulat...

Embodiment 2

[0046] Such as Figure 5 It is shown that a reformer manufacturing process of methanol water hydrogen production equipment, including the manufacturing process of the mica shell of the reformer shell, the manufacturing process of the thermal insulation cotton layer of the reformer shell and the stainless steel inner shell of the reformer shell Manufacturing process, of which:

[0047] The manufacturing process of the mica shell of the reformer shell comprises the following steps:

[0048] (1) Mica, aluminosilicate, carbonate and high refractoriness inorganic minerals are crushed and ground into powders with a size of 50 μm ~ 300 μm, calculated according to the total weight of 100, and the ratio is 35 ~ 45: 25 ~ 35: 10~15: 5~15 Take materials and mix them, and stir them evenly;

[0049] (2) Add 10-15% binder of the total weight of the mixture to evenly mix and bond the mixture;

[0050] (3) Under static pressure conditions with a pressure of 15-25Mpa, the mixed binder is sta...

Embodiment 3

[0054] Such as Image 6 As shown, the difference between this embodiment and Embodiment 2 is that the manufacturing process of the reformer in this embodiment also includes the manufacturing process of the mica base of the reformer, the mica exhaust pipe and the mica check valve. The manufacturing process includes the following steps:

[0055] (1) Crush and grind mica, aluminosilicate, carbonate and high-refractoriness inorganic minerals respectively into powders with a size of 50 μm to 300 μm, calculated according to the total weight of 100, and the ratio is 35~45:25~ 35: 10~15: 5~15 Take materials and mix them, and stir them evenly;

[0056] (2) Add 10-15% binder of the total weight of the mixture to evenly mix and bond the mixture;

[0057] (3) Under the static pressure condition of 15-25Mpa, the mixed binder is statically pressed into mica base, mica exhaust pipe and mica check valve;

[0058] (4) Send the mica shell formed by static pressure into the barbecue oven, grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com