Preparation method of silver nanoparticle with controllable particle size

A technology of silver nanoparticles and particle size, applied in nanotechnology and other directions, can solve the problems of product size, shape, difficult to control, harsh high temperature reaction conditions, complex preparation process, etc., and achieve the effects of simple equipment, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

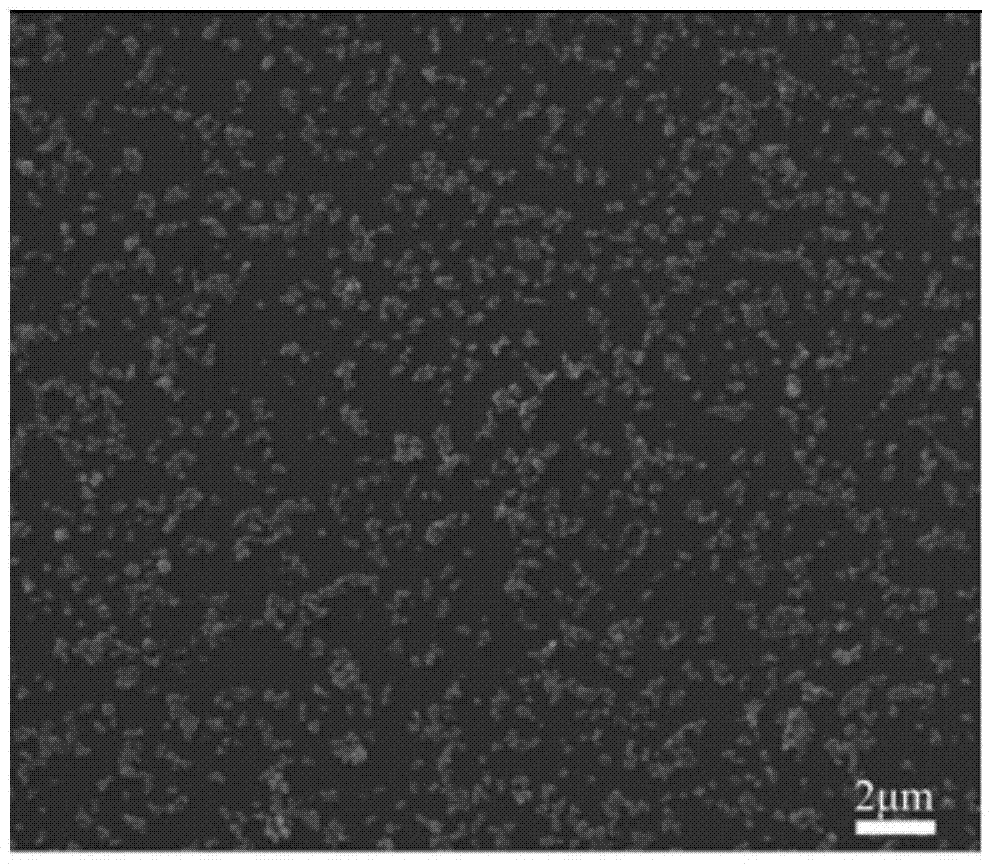

Image

Examples

Embodiment 1

[0026] The preparation method of silver nanoparticles of the present embodiment comprises the following steps:

[0027] 1) Dissolve 0.169 g of silver nitrate and 0.15 g of polyvinylpyrrolidone in 50 ml of ethylene glycol to form solution A; weigh 0.0175 g of sodium chloride and dissolve in 20 ml of ethylene glycol to form solution B;

[0028] 2) Mix 50 ml of solution A and 20 ml of solution B as a reaction solution and transfer it to an Erlenmeyer flask, and place it in a microwave for 0.5 hours to react to obtain silver nanoparticles;

[0029] 3) After microwave irradiation reaction, centrifuge the suspended reaction solution, and then wash the precipitate with deionized water and absolute ethanol;

[0030] 4) Dry the precipitate in a vacuum drying oven at 50°C for 5 hours to obtain black silver powder.

[0031] A certain amount of surfactant polyvinylpyrrolidone is added to the silver nitrate solution, the purpose is to control the morphology of the product, and also to pre...

Embodiment 2

[0033] The preparation method of silver nanoparticles of the present embodiment comprises the following steps:

[0034] 1) Dissolve 0.169 g of silver nitrate and 0.15 g of polyvinylpyrrolidone in 50 ml of ethylene glycol to form solution A; weigh 0.0297 g of sodium chloride and dissolve in 20 ml of ethylene glycol to form solution B;

[0035] 2) Mix 50 ml of solution A and 20 ml of solution B as a reaction solution and transfer it to an Erlenmeyer flask, and place it in a microwave for 0.5 hours to react to obtain silver nanoparticles;

[0036] 3) After microwave irradiation reaction, centrifuge the suspended reaction solution, and then wash the precipitate with deionized water and absolute ethanol;

[0037] 4) Dry the precipitate in a vacuum drying oven at 50°C for 5 hours to obtain black silver powder.

[0038] A certain amount of surfactant polyvinylpyrrolidone is added to the silver nitrate solution, the purpose is to control the morphology of the product, and also to pre...

Embodiment 3

[0040] The preparation method of the cobalt nanospheres of this embodiment comprises the following steps:

[0041] 1) Dissolve 0.169 g silver nitrate and 0.15 g polyvinylpyrrolidone in 50 ml ethylene glycol to make solution A; weigh 0.0597 g sodium chloride and dissolve it in 20 ml deionized water to make solution B;

[0042] 2) Mix 50 ml of solution A and 5 ml of solution B as a reaction solution and transfer it to an Erlenmeyer flask, and place it in a microwave for 0.5 hours to react to obtain silver nanoparticles;

[0043] 3) After microwave irradiation reaction, centrifuge the suspended reaction solution, and then wash the precipitate with deionized water and absolute ethanol;

[0044] 4) Dry the precipitate in a vacuum drying oven at 40°C for 6 hours to obtain black silver powder.

[0045] A certain amount of surfactant polyvinylpyrrolidone is added to the silver nitrate solution, the purpose is to control the morphology of the product, and also to prevent particle aggl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com