Ore dressing method for comprehensively recovering gold, zinc, sulfur and iron from abandoned tailing

A technology for waste tailings and beneficiation methods, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of poor selectivity of metal minerals and difficulty in recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

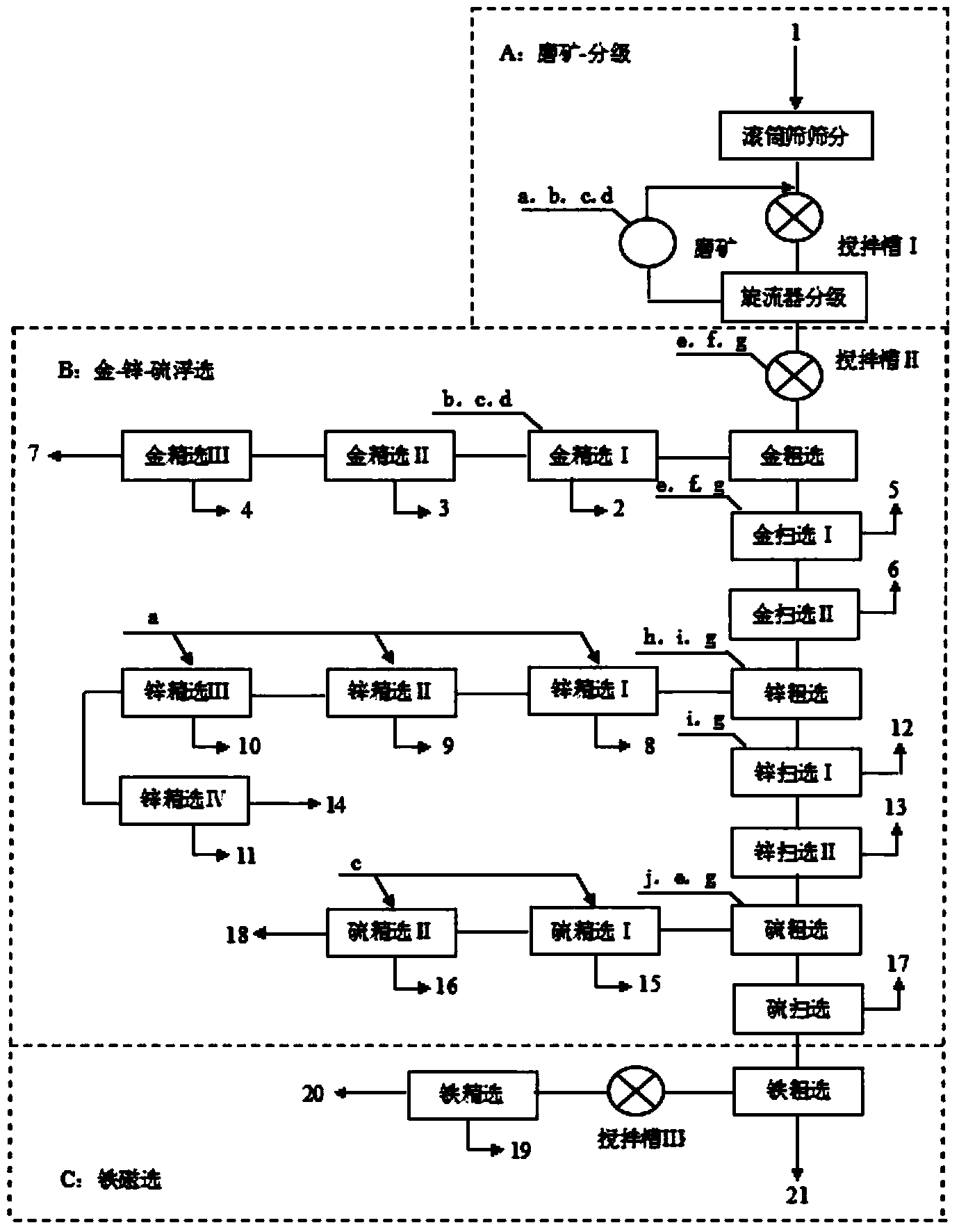

[0014] Example 1: Firstly, the waste tailings are wet-screened with a trommel screen to remove larger pieces of gravel with a particle size of more than 2 mm. The material under the screen is fed into the mixing tank for slurry adjustment and then enters the cyclone for classification. The cyclone is classified. The returned sand is fed into the ball mill for grinding, and the ball mill is discharged and then returned to the mixing tank. According to the dry weight of waste tailings per ton, add 500g / t of calcium oxide, 1000g / t of zinc sulfate, 250g / t of water glass and 250g / t of sodium hexametaphosphate into the ball mill. The graded overflow of the cyclone with a grinding fineness of -0.038mm accounting for 90% is fed to another stirring tank, and the amount of ethyl xanthate 60g / t and the amount of ethyl diazepam 60g / t are sequentially added to the stirring tank. t and 30g / t of pine alcohol oil to adjust the pulp, so that the pH value of the pulp is 7.5-8.5, firstly carry o...

Embodiment 2

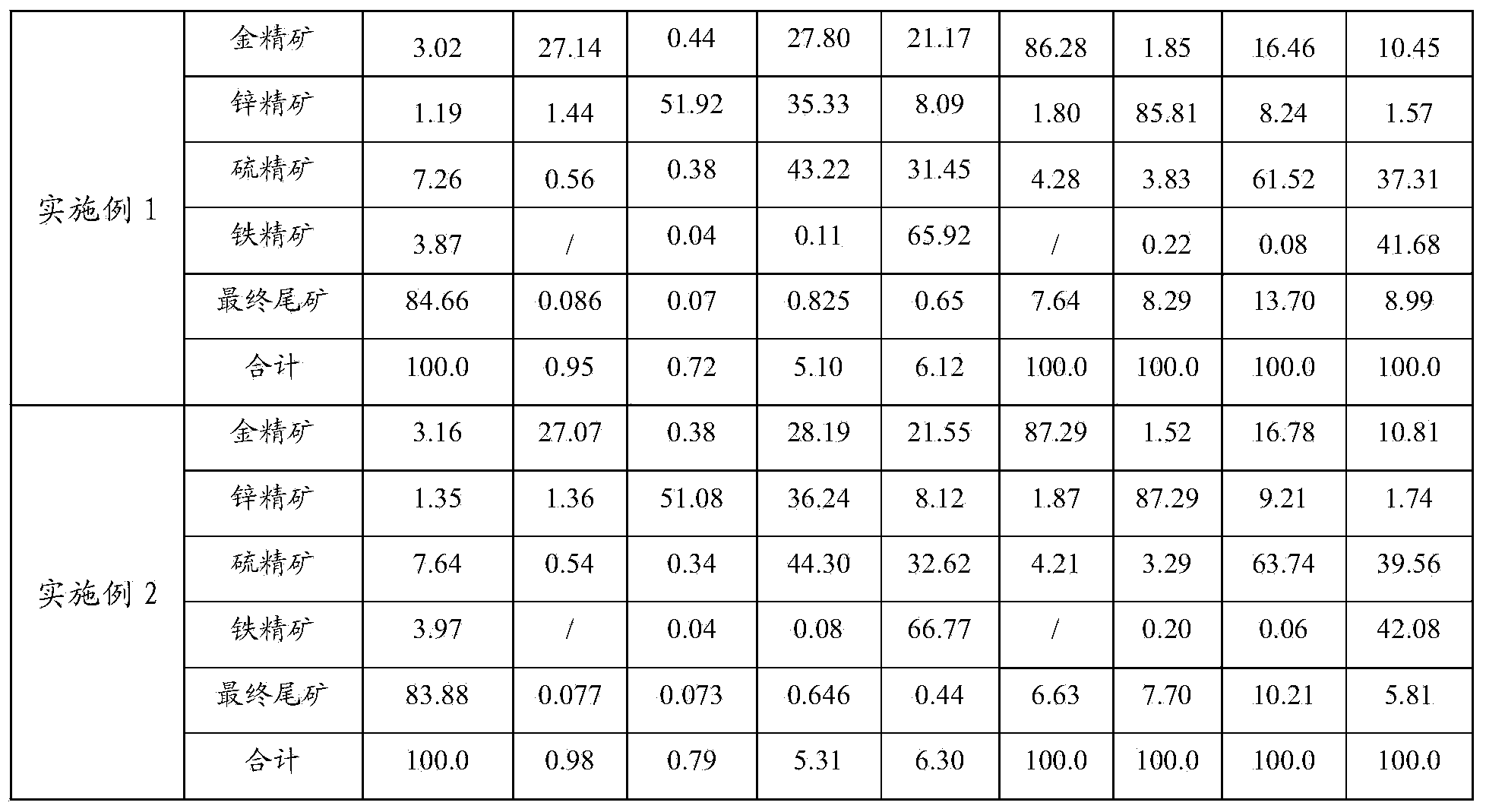

[0015] Embodiment 2: according to figure 1 The embodiment of the technological process of the present invention, the test steps, process parameters, and medicament system are exactly the same as those in Example 1. The result of the embodiment of the present invention is shown in Table 1. Show by the result shown in table 1, adopt the inventive method, the beneficiation index that embodiment 1 obtains is: gold concentrate grade 27.14g / t, gold recovery rate 86.28%, zinc concentrate grade 51.92%, zinc recovery rate 85.81%, The sulfur concentrate grade is 43.22%, the sulfur recovery rate is 61.52%, the iron concentrate grade is 65.92%, and the iron recovery rate is 41.68%. Example 2 Mineral processing indicators: gold concentrate grade 27.07g / t, gold recovery rate 87.29%, zinc concentrate grade 51.08%, zinc recovery rate 87.29%, sulfur concentrate grade 44.30%, sulfur recovery rate 63.74%, iron concentrate The grade is 66.77%, and the iron recovery rate is 42.08%. It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com