A kind of treatment method of antibiotic fermentation bacteria residue

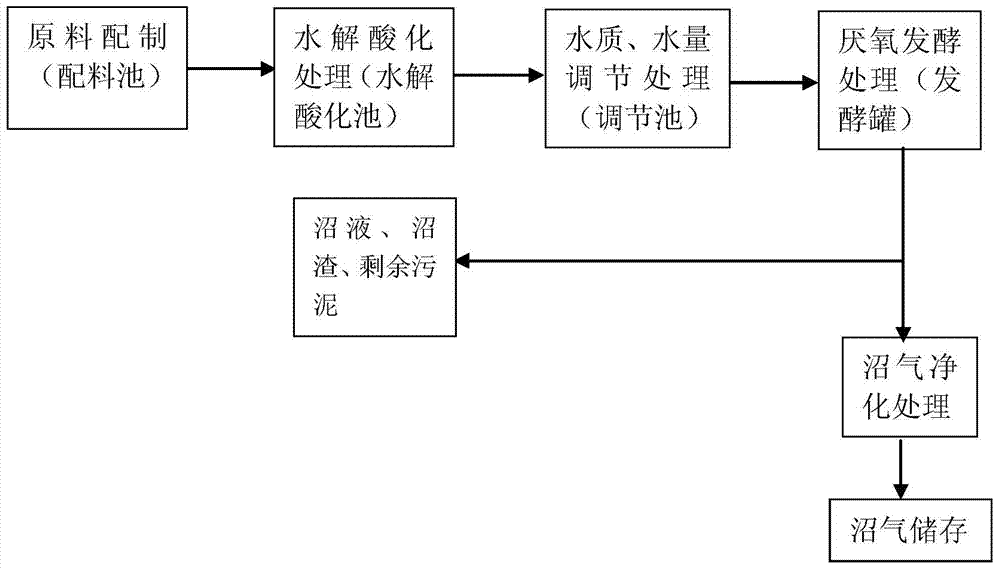

A treatment method and fermentation bacteria technology, which is applied in the field of high-efficiency fermentation treatment process of lincomycin hydrochloride and gentamicin residues, can solve the problems of increasing the load of anaerobic fermentation tanks, residual precipitation of bacteria residues, increasing gas production, etc. , to achieve the effect of improving biodegradability, reducing pollution and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

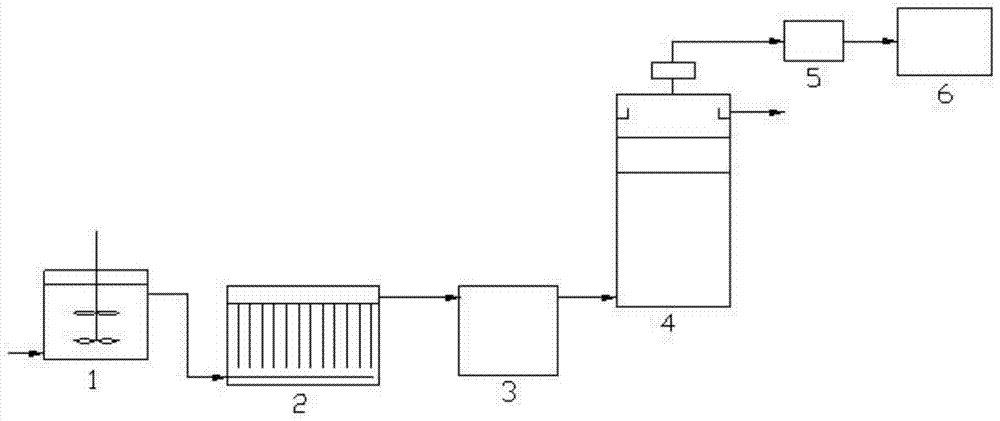

[0061] 1. Preparation of fermentation suspension

[0062] Put the gentamicin residue and lincomycin hydrochloride residue into the batching tank 1 according to the weight ratio of 1:2, the total weight of gentamicin residue and lincomycin hydrochloride is 0.33kg, then pass into water in batching tank 1, stir and mix evenly, be mixed with the bacterium residue suspension that solid content is 6.6%, the chemical oxygen demand COD of bacterium residue suspension is 33000mg / L;

[0063] In the present invention, the water passed into the batching tank can be selected from tap water, reused water, and the effluent of the secondary sedimentation tank for sewage treatment of relevant antibiotic production units. Except for tap water, other chromaticity≤30; pH: 6.5-7.5; COD≤100mg / L; SS≤30mg / L; NH 3 - Water with N≤20mg / L; TP≤1mg / L is applicable to the present invention.

[0064] 2. Hydrolysis and acidification treatment

[0065] Pass the suspension of bacterial residue into the hydr...

Embodiment 2

[0083] 1. Raw material preparation

[0084] Put the gentamicin residue and lincomycin hydrochloride residue into the batching pool 1 according to the weight ratio of 1:2.5, the total weight of gentamicin residue and lincomycin hydrochloride is 0.35kg, then pass into water in batching tank 1, stir and mix evenly, be mixed with the bacterium slag suspension that solid content is 7%, the chemical oxygen demand COD of bacterium slag suspension is 35000mg / L;

[0085] 2. Hydrolysis and acidification treatment

[0086] Pass the suspension of bacterial residue into the hydrolytic acidification tank 2 and carry out hydrolysis and acidification treatment on the suspension of bacterial residue under stirring state to obtain a mixed solution of hydrolyzed bacterial residue, wherein the hydrolytic acidification tank is filled with Akeman ecological base filler, and the filling ratio of the filler is 32%; the lignin-degrading bacteria Bacillus licheniformis CH15 cultivated by the Institute...

Embodiment 3

[0092] 1. Raw material preparation

[0093] The gentamicin slag and lincomycin hydrochloride slag are put into batching pool 1 according to the weight ratio of 1:1.5, the total weight of gentamicin slag and lincomycin hydrochloride is 0.25kg, then pass into water in batching tank 1, stir and mix evenly, be mixed with the bacterium residue suspension that solid content is 6%, the chemical oxygen demand COD of bacterium residue suspension is 30000mg / L;

[0094] 2. Hydrolysis and acidification treatment

[0095] Pass the suspension of bacterial residue into the hydrolytic acidification tank 2 and carry out hydrolysis and acidification treatment on the suspension of bacterial residue under stirring state to obtain a mixed solution of hydrolyzed bacterial residue, wherein the hydrolytic acidification tank is filled with Akeman ecological base filler, and the filling ratio of the filler is 28%; the lignin-degrading bacteria Bacillus licheniformis CH15 cultivated by the Institute of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com