Rubber asphalt, preparation and application thereof

A technology of rubber asphalt and asphalt, which is applied in the composition and preparation of high-performance, environmentally friendly and stable rubber asphalt, which can solve the problems of performance attenuation, rubber asphalt storage segregation, easy precipitation, etc., achieve good elastic performance and storage resistance, and achieve low temperature Effects of environmentally friendly processing, easy swelling and reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

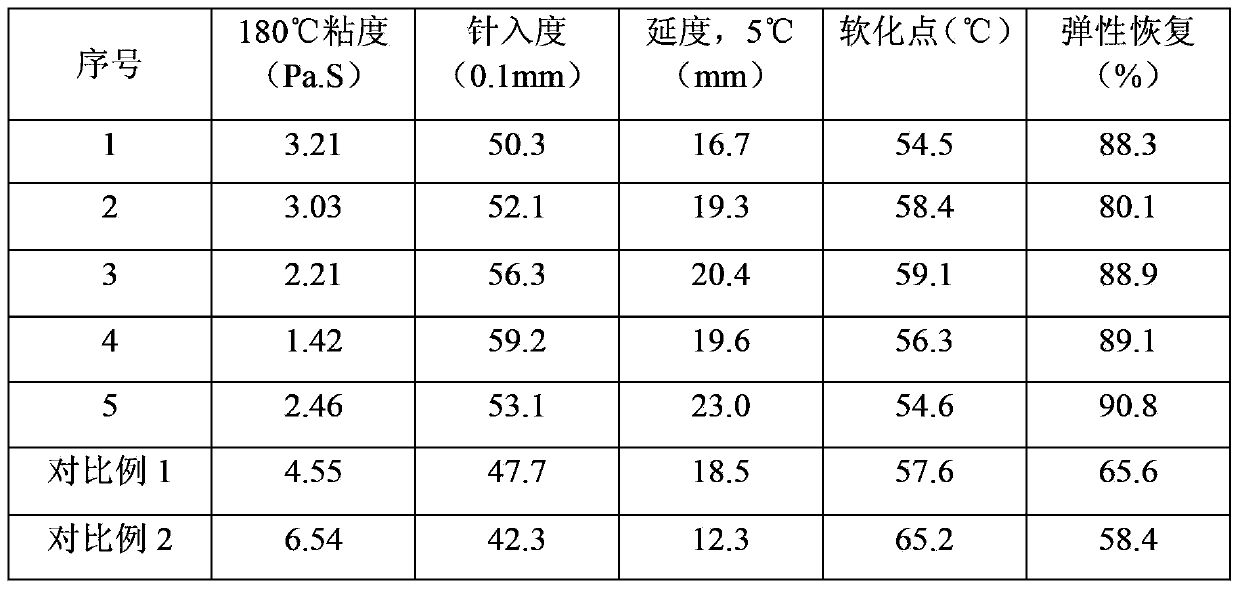

Examples

Embodiment 1

[0022] Weigh 1000g of rubber powder processed from waste tires, the mesh number is 30 mesh, extract oil from 100g of furfural, and put 150g of polyolefin elastomer into a mixer for mixing. The extruder is extruded, the extrusion temperature is 190°C, the extruded material is desulfurized and devolatilized by the extruder, and the extruded material is made into pellets through the die face pelletizing equipment, the size of the pellets is 2-6mm, and the density is 0.85g / cm 3 , Weigh 0.5% of the weight of desulfurization and devolatilization granules as a cross-linking agent, add the mixture of cross-linking agent and desulfurization and devolatization granules to Kunlun No. 70 asphalt in a proportion of 20% to prepare asphalt modified granules. Shear at high temperature for 20 minutes to prepare rubber asphalt.

Embodiment 2

[0024] Weigh 1000g of rubber powder processed from waste tires, the mesh number is 30 mesh, extract oil from 100g of furfural, and put 150g of polyolefin elastomer into a mixer for mixing. The extruder is extruded, the extrusion temperature is 220°C, the extruded material is desulfurized and devolatilized by the extruder, and the extruded material is made into granules through the die surface granulation equipment, the size of the granules is 2-6mm, and the density is 0.85g / cm 3 , Weigh 0.5% of the weight of sulfur desulfurization and devolatilization particles as a reactive cross-linking agent, and add the mixture of cross-linking agent and desulfurization and devolatization particles into Kunlun No. 70 asphalt in a proportion of 20% to prepare asphalt modified particles. The rubber asphalt was prepared by shearing at ℃ for 20 minutes.

Embodiment 3

[0026]Weigh 1000g of rubber powder processed from waste tires, the mesh number is 30 mesh, extract oil from 100g of furfural, and put 150g of polyolefin elastomer into a mixer for mixing at a mixing temperature of 50-80°C, and extrude the mixture with reclaimed rubber desulfurization The extruder is extruded, the extrusion temperature is 250°C, the extruded material is desulfurized and devolatilized by the extruder, and the extruded material is made into granules through the die surface granulation equipment, the size of the granules is 2-6mm, and the density is 0.85g / cm 3 , Weigh 0.5% of the weight of sulfur desulfurization and devolatilization particles as a reactive cross-linking agent, and add the mixture of cross-linking agent and desulfurization and devolatization particles into Kunlun No. 70 asphalt in a proportion of 20% to prepare asphalt modified particles. The rubber asphalt was prepared by shearing at ℃ for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com