Preparation method of heat-resisting PVC (polyvinyl chloride)/ABS (acrylonitrile butadiene styrene)/PMMA (polymethyl methacrylate) alloy material

A technology of alloy material and high temperature resistance, which is applied in the field of polymer materials, can solve the problems of wear resistance decline and achieve good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

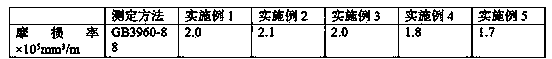

Examples

Embodiment 1

[0032] A preparation method of a high temperature resistant PVC / ABS / PMMA alloy material, comprising the following methods:

[0033] Step 1: Mix PVC140Kg, ABS10Kg, PMMA15Kg, fluorine rubber 4Kg, white carbon black 15Kg, dioctyl phthalate 5Kg, aluminum stearate 4Kg, layered silica thin rock powder 6Kg, clay 8Kg, silicon micropowder (400 Add 3Kg (mesh to 600 mesh) and 6Kg zinc oxide into the mixer, heat up, the temperature is 70°C, stir evenly, the stirring speed is 500rpm, the stirring time is 20min, and the material is cooled;

[0034] Step 2: Extrude the cooling material obtained in the first step with a twin-screw extrusion granulator, and the extrusion temperature is 190°C to obtain granules A;

[0035] The 3rd step: the particle A obtained in the 2nd step, 5Kg of chlorinated polyethylene elastomer and 4Kg of triallyl isocyanate are stirred and mixed uniformly, and the stirring speed is 700rpm;

[0036] Step 4: Add the mixture obtained in Step 3 into a single-screw extruder...

Embodiment 2

[0039] A preparation method of a high temperature resistant PVC / ABS / PMMA alloy material, comprising the following methods:

[0040] Step 1: Mix PVC180Kg, ABS12Kg, PMMA20Kg, fluororubber 6Kg, white carbon black 20Kg, dioctyl phthalate 10Kg, aluminum stearate 6Kg, layered silica thin rock powder 12Kg, pottery clay 14Kg, silicon micropowder (400 Add 6Kg of mesh to 600 mesh) and 10Kg of zinc oxide into the mixer, heat up, the temperature is 90°C, stir evenly, the stirring speed is 700rpm, the stirring time is 30min, and the material is discharged and cooled;

[0041] Step 2: Extrude the cooling material obtained in the first step with a twin-screw extrusion granulator at a temperature of 200°C to obtain granules A;

[0042] The 3rd step: the particle A obtained in the 2nd step is mixed with chlorinated polyethylene elastomer 10Kg and triallyl isocyanate 6Kg in stirring, and the stirring speed is 800rpm;

[0043] Step 4: Add the mixture obtained in Step 3 into a single-screw extru...

Embodiment 3

[0046] A preparation method of a high temperature resistant PVC / ABS / PMMA alloy material, comprising the following methods:

[0047] Step 1: Mix PVC160Kg, ABS11Kg, PMMA17Kg, fluororubber 5Kg, white carbon black 17Kg, dioctyl phthalate 7Kg, aluminum stearate 5Kg, layered silica thin rock powder 8Kg, clay 12Kg, silicon micropowder (400 Add 5Kg (mesh to 600 mesh) and 7Kg zinc oxide into the mixer, heat up, the temperature is 80°C, stir evenly, the stirring speed is 600rpm, the stirring time is 25min, and the material is cooled;

[0048] Step 2: Extrude the cooling material obtained in Step 1 with a twin-screw extrusion granulator, and the extrusion temperature is 195°C to obtain granules A;

[0049] The 3rd step: the particle A obtained in the 2nd step, 7Kg of chlorinated polyethylene elastomer and 5Kg of triallyl isocyanate are stirred and mixed evenly, and the stirring speed is 750rpm;

[0050] Step 4: Add the mixture obtained in Step 3 into a single-screw extruder, and perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com