Industrialized production method for producing high-content natural vitamin E by utilizing hydrolysis reduction process

A technology of natural vitamins and production methods, which is applied in the field of producing high-content vitamin E, and can solve the problems of large floor area, large amount of sewage treatment, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

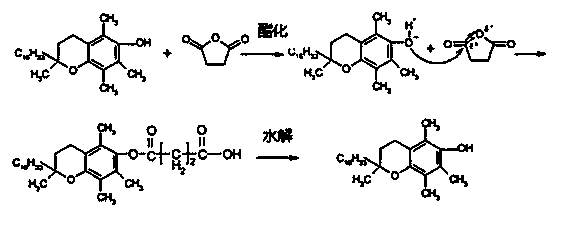

Method used

Image

Examples

Embodiment 1

[0040] 50 kg of low-content natural mixed tocopherols (vitamin E), wherein the content of mixed tocopherols is 38.2%, add 5.5 kg of succinic anhydride, 10 kg of sodium hydroxide, and 150 kg of methyl ethyl ketone, and esterify at 40 degrees Celsius for 6 hours; After the esterification is completed, butanone is distilled off under reduced pressure, and 250 kg of cyclohexane is added to wash with water, and 100 kg of water is added each time, washed three times until neutral, cooled to 15 degrees Celsius and left to crystallize for 12 hours; the crystalline solid is separated and dried to obtain Natural Tocopheryl Succinate. The content of natural tocopherol succinate is 93.6%.

[0041] After many times of the above operations, take 50 kg of natural tocopherol succinate (content 93.6%), 100 kg of ethanol, and 10 kg of 50% potassium hydroxide solution for hydrolysis. The hydrolysis temperature is 70 degrees Celsius and the hydrolysis time is 4 hours. After hydrolysis Add 100 kg...

Embodiment 2

[0043]50 kg of low-content natural mixed tocopherols (vitamin E), of which the content of mixed tocopherols is 18.5%, is added with 3 kg of succinic anhydride, 10 kg of potassium hydroxide, and 150 kg of acetone, and esterified at 65 degrees Celsius for 4 hours. After the esterification is completed, distill off the acetone and add 250 kg of petroleum ether to wash with water, adding 100 kg of water each time, washing three times until neutral. After the water was removed, the temperature was lowered to 10 degrees Celsius and left to stand for crystallization for 12 hours. The crystalline solid was separated and dried to obtain natural tocopherol succinate with a content of 92.6%.

[0044] After multiple times of the above operations, take 50 kg of natural tocopheryl succinate (92.6% content), 150 kg of methanol, and 10 kg of 50% sodium hydroxide solution for hydrolysis. The hydrolysis temperature is 60 degrees Celsius, and the hydrolysis time is 6 hours. After hydrolysis, 150...

Embodiment 3

[0046] Low-content natural mixed tocopherols (vitamin E) 50 kg, wherein the content of mixed tocopherols is 42.2%, add 5.8 kg of succinic anhydride, 15 kg of triethylamine, 150 kg of petroleum ether, carry out esterification at 65 degrees Celsius for 5 hours . After the esterification, the petroleum ether was removed by evaporation, and 250 kg of n-hexane was added to wash with water, and 100 kg of water was added each time, and washed three times until neutral. After the water is taken out, the temperature is lowered to 15 degrees Celsius for crystallization, and the natural tocopheryl succinate is obtained after separation, and its content is 92.5%.

[0047] After multiple times of the above operations, take 50 kg of natural tocopheryl succinate (92.5% content), 100 kg of methanol, and 10 kg of 50% sodium hydroxide solution for hydrolysis. The hydrolysis temperature is 65 degrees Celsius, and the hydrolysis time is 5 hours. After hydrolysis, add 150 kg of petroleum ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com