Concentration method for low-content natural mixed tocopherol

A tocopherol, low-content technology, applied in the field of chemical engineering, can solve the problems of large sewage treatment volume, use of labor, complex production equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

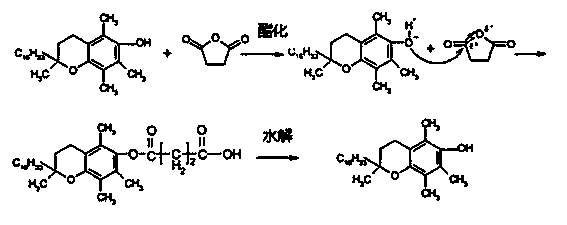

Method used

Image

Examples

Embodiment 1

[0034] A method for concentrating low-content natural mixed tocopherols, comprising adding 50 g of natural mixed tocopherols with a mixed tocopherol content of 38.2%, 5.5 g of succinic anhydride, 10 g of sodium hydroxide and 10 g of butanone, and stirring at 40° C. for 6 hours; After the reaction was over, butanone was distilled off under reduced pressure, and 250g of cyclohexane was added to wash with water to neutrality, cooled to 10°C and allowed to stand for crystallization for 24 hours, the crystalline solid was separated and dried to obtain natural tocopherol succinate; take 50g of natural tocopherol Add 100g of ethanol and 10g of 50% potassium hydroxide solution to the succinate for hydrolysis. The hydrolysis temperature is 60°C and the hydrolysis time is 4 hours. After hydrolysis, 100g of cyclohexane is added to wash with water until neutral. After recovery of cyclohexane by pressure distillation, 40 g of mixed tocopherol concentrate with mixed tocopherol content greate...

Embodiment 2

[0036] A method for concentrating low-content natural mixed tocopherols, comprising 50 g of natural mixed tocopherols with a mixed tocopherol content of 18.5%, adding 3 g of succinic anhydride, 10 g of sodium hydroxide and 150 g of butanone, and stirring at 60° C. for 4 hours; After the end, the methyl ethyl ketone was distilled off under reduced pressure, and 250g cyclohexane was added to wash with water to neutrality, and the temperature was lowered to 13°C to stand for crystallization for 20 hours, and the crystalline solid was separated and dried to obtain natural tocopherol succinate; natural tocopherol succinic acid Add 150g of ethanol and 10g of 50% potassium hydroxide solution to 50g of ester for hydrolysis. The hydrolysis temperature is 65°C and the hydrolysis time is 5 hours. After hydrolysis, add 150g of cyclohexane to wash with water until neutral, and decompress the solvent layer after separation. After recovering cyclohexane by distillation, a mixed tocopherol con...

Embodiment 3

[0038] A method for concentrating low-content natural mixed tocopherols, comprising adding 50 g of natural mixed tocopherols with a mixed tocopherol content of 42.2%, 5.8 g of succinic anhydride, 15 g of sodium hydroxide and 150 methyl ethyl ketone, and stirring at 70° C. for 6 hours; After the reaction was over, butanone was distilled off under reduced pressure, and 250 g of cyclohexane was added to wash with water to neutrality, and the temperature was lowered to 15° C. to stand for crystallization for 24 hours. The crystalline solid was separated and dried to obtain natural tocopherol succinate; natural tocopherol succinate Add 100g of ethanol and 10g of 50% potassium hydroxide solution to 50g of ester for hydrolysis. The hydrolysis temperature is 70°C and the hydrolysis time is 6 hours. After hydrolysis, 150g of cyclohexane is added to wash with water until neutral. After recovery of cyclohexane by pressure distillation, a mixed tocopherol concentrate with a mixed tocophero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com