Amorphous metal glass forming system and process with cold-hot circulation

A metal glass, cold and heat cycle technology, used in metal processing equipment, manufacturing tools, heating/cooling equipment, etc., can solve the problems of amorphous alloys that cannot achieve uniform temperature, low production efficiency, and uneven deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

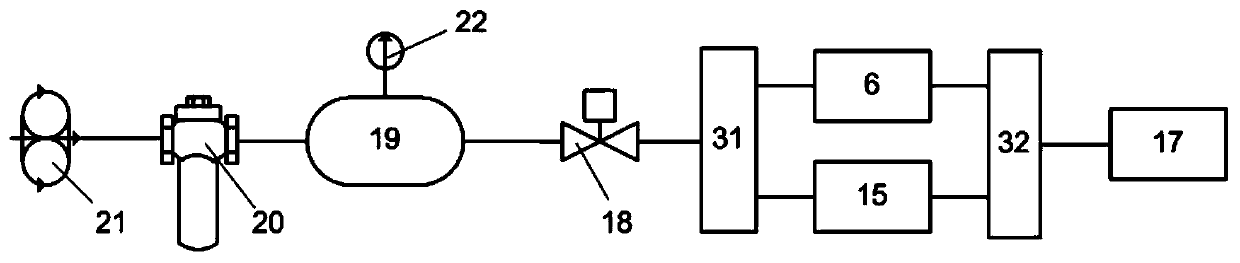

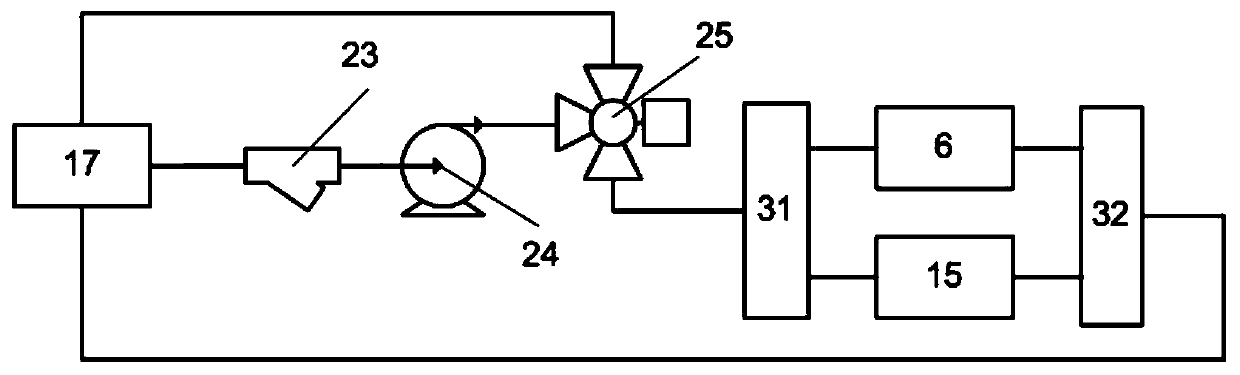

[0036] An amorphous metallic glass forming system with a cooling and heating cycle, comprising an upper mold 6 fixed on the upper workbench 8 of the forming equipment, a lower mold 15 fixed on the lower workbench 13 of the forming equipment, and the bottom of the lower mold 15 The ejection mechanism 14 that connects is all provided with electric heating element 29 in upper mold 6 and lower mold 15, and electric heating element 29 is connected with temperature control device 2 by wire, and upper mold 6 and lower mold 15 are all provided with cooling passage. hole, the copper tube 28 is placed in the cooling through hole, the copper tube 28 is the common channel of cooling water and high-pressure gas, communicates with the external cooling water device 4 and high-pressure gas device 5, and has Blind hole and a contact temperature measuring device 30 is placed in the blind hole. There is a non-contact temperature measuring device 11 for testing the temperature of the blank at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flow stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com