A kind of water-soluble hydrophobic association polymer and preparation method thereof

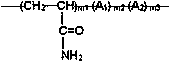

A hydrophobic association, polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of poor temperature resistance and salt resistance, difficult to meet the requirements of high temperature and high salt oil fields, poor shear stability, etc. problems, to achieve excellent temperature and salt resistance, good temperature resistance, and good shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In order to overcome the problems that the existing HPAM products have poor temperature and salt resistance, poor shear stability, and difficulty in meeting the use requirements of high-temperature and high-salt oilfields for enhanced recovery. This example provides a water-soluble hydrophobic association polymer and its preparation method. The raw material formula of the polymer is as follows: by mass percentage, acrylamide is 16% to 26%, hydrophobic monomer is 0.08% to 0.1%, and hydrophilic Water monomer 2.6%~9%, persulfate 0.03%~0.08%, sodium lauryl sulfate 3%~5%, defoamer 0.002%~0.004%, deionized water 60%~81.3%.

[0035] The preparation method of this water-soluble hydrophobic association polymer of the present invention comprises the following steps:

[0036] Step 1): 16% to 26% of acrylamide monomer is placed in a jar, and 30% to 41.3% of deionized water is added to dissolve;

[0037] Step 2): Put 0.08%~0.1% hydrophobic monomer and 3%~5% sodium lauryl sulfate in...

Embodiment 2

[0043] This embodiment provides a water-soluble hydrophobic association polymer, and its preparation method is as follows:

[0044] Dissolve 16g of acrylamide monomer in 41.3g of deionized water and place it in a jar; first dissolve 0.08g of tetradecyl methacrylate and 3g of sodium lauryl sulfate in 40g of deionized water in a beaker, and then Move the mixed solution in the beaker into the jar, and add 2.6g sodium allyl sulfonate into it at the same time; stir the mixed solution in the jar with an electric mixer, let it stand for 12 minutes, and then pour it into the jar Nitrogen gas was introduced, 0.002 g of defoamer was added, and nitrogen was passed to remove oxygen for 15 minutes at room temperature. Add 0.015g of potassium persulfate, initiate at 35°C for 20 minutes, then add 0.015g of potassium persulfate, initiate at 60°C for 45 minutes, stop nitrogen flow, and polymerize at constant temperature for 10 hours to obtain a colloidal polymerization product; colloidal polym...

Embodiment 3

[0051] This embodiment provides a water-soluble hydrophobic association polymer, and its preparation method is as follows:

[0052]Dissolve 20g of acrylamide monomer in 35g of deionized water and place it in a jar; first dissolve 0.09g of tetradecyl methacrylate and 4g of sodium lauryl sulfate in 40g of deionized water in a beaker, and then put The mixed solution in the beaker was moved into a jar, and 5g of sodium allyl sulfonate was added thereinto at the same time; stirred with an electric mixer for 5 minutes, allowed to stand for 15 minutes, then nitrogen gas was introduced into the jar, and 0.003g of defoaming agent was added agent, nitrogen deoxygenation at room temperature for 30 minutes. Add 0.03g of ammonium persulfate, initiate at 30°C for 20 minutes, then add 0.03g of ammonium persulfate, initiate at 65°C for 55 minutes, stop nitrogen flow, and polymerize at constant temperature for 12 hours to obtain a colloidal polymerization product; colloidal polymerization prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com